Perilla flavone and perilla flavone derivative extraction method

A technology of flavonoids and extraction methods in perilla, which is applied in the field of extraction of flavonoids and derivatives in perilla, and can solve the problems of few reports of flavonoids in perilla

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

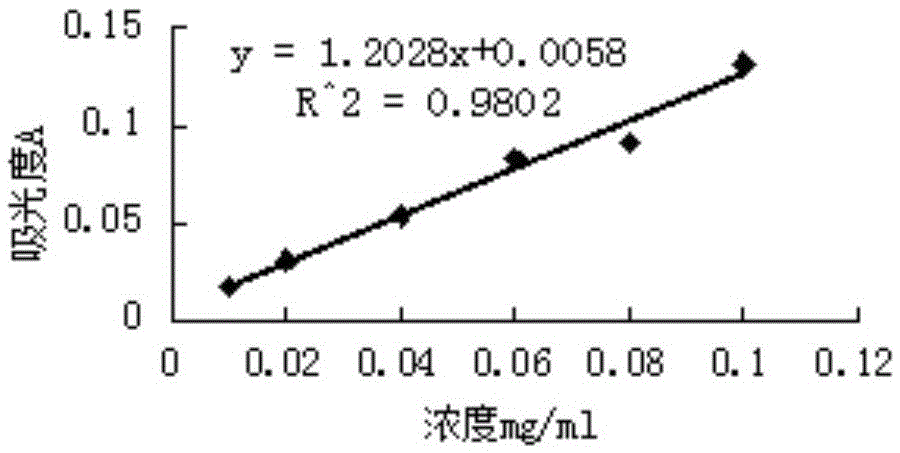

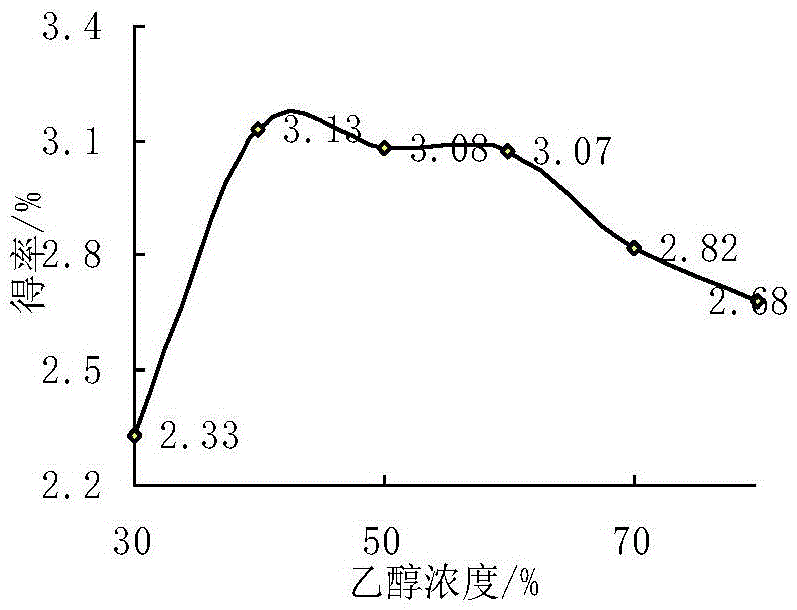

[0039] According to the extraction method of the technical scheme of the content of the invention, using ethanol as a solvent, the influence of ethanol volume (30%, 40%, 50%, 60%, 70%, 80%) on the yield of flavonoids was investigated respectively. The concentration of flavonoids was determined using rutin standard curve with absorbance. The formula for calculating the yield of flavonoids is:

[0040] Yield of total flavonoids in perilla = (total amount of flavonoids in crude extract / mass of perilla leaf) × 100%, the following calculation method is the same.

[0041] Depend on figure 2 It can be seen that there is a curvilinear relationship between ethanol concentration and flavonoid yield, and the yield of flavonoid extracted by different concentrations of ethanol is quite different. The yield of flavonoids increased sharply when the ethanol concentration was 30%-40%; the yield was relatively stable when the concentration was 40%-60% (the difference was only 0.06%); the ext...

Embodiment 2

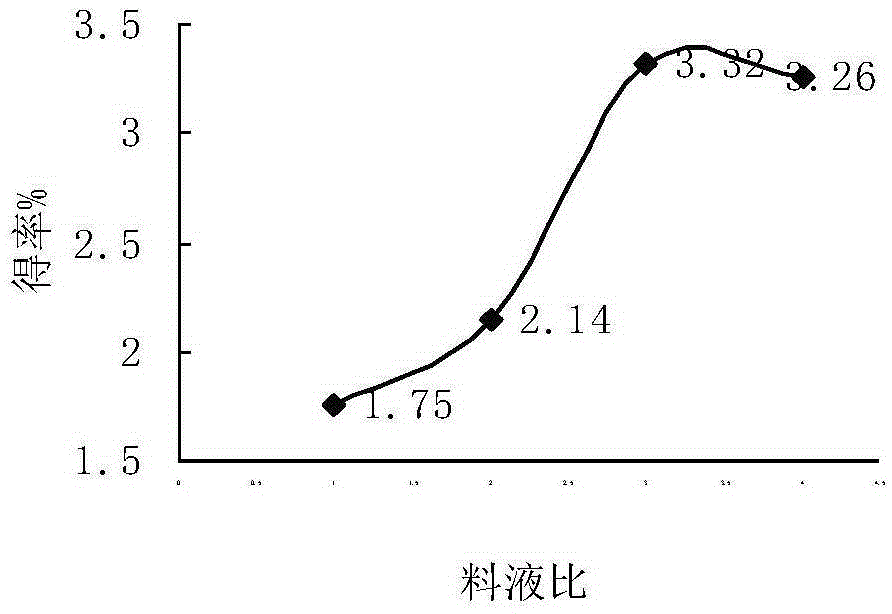

[0043] According to the extraction method of the technical scheme of the content of the invention, using ethanol as a solvent, the influence of the ratio of ethanol to liquid (1:20, 1:30, 1:40, 1:50) on the yield of flavonoids was investigated respectively. The calculation formula and calculation method are the same as above. Depend on image 3 It can be seen that with the increase of solid-liquid ratio, the yield of flavonoids gradually increased. When the ratio of solid to liquid was 1:40, the highest yield of total flavonoids was 3.32%. When the ratio of solid to liquid was 1:50, the extraction rate decreased slightly. Therefore, 1:30, 1:40, and 1:50 are selected as the conditions for the orthogonal test.

Embodiment 3

[0045] According to the extraction method of the technical scheme of the content of the invention, different ultrasonic treatment times (20, 30, 40, 50, 60 min) were selected to investigate the influence on the yield of flavonoids.

[0046] Depend on Figure 4 It can be seen that the yield of flavonoids gradually increases when the ultrasonic treatment time is 20-40. Because the cavitation and oscillation of ultrasonic waves are beneficial to the dissolution of intracellular substances. However, the extraction rate began to decrease when the ultrasonic treatment time exceeded 40 min, which may be because the structure and biological activity of flavonoids were destroyed by long-term ultrasonic treatment. Therefore, an ultrasonic time of 30 to 50 min was selected for orthogonal experiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com