A nitrogen-doped carbon/carbon nitride photocatalyst material and its one-step synthesis method

A technology of nitrogen-doped carbon and synthesis method, which is applied in the field of photocatalysis and can solve problems such as environmental hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] Its specific preparation method steps are as follows:

[0021] 1) take a certain quality of urea and place it in the crucible, and the quality of the urea is 20g;

[0022] 2) take a small amount of citric acid, and evenly disperse it into the urea taken in step 1), the quality of citric acid is 10-1000mg;

[0023] 3) Cover the crucible in step 2, place it in a muffle furnace, and calcine it for 2-4 hours to obtain a nitrogen-doped carbon / carbon nitride photocatalyst material.

[0024] As a preferred solution, urea is used as the carbon nitride precursor.

[0025] As a preferred solution, a trace amount of citric acid is used as the carbon source.

[0026] As a preferred solution, the calcination temperature in step 3) is 400-600°C, and the holding time is 2-4h.

[0027] The photocatalytic performance of nitrogen-doped carbon / carbon nitride photocatalysts was evaluated by splitting water for hydrogen production under visible light (λ≥420 nm). The experimental procedu...

Embodiment 1

[0032] A one-step synthesis method of a nitrogen-doped carbon / carbon nitride photocatalyst is as follows: 1) weigh a certain mass of urea and place it in a crucible, and the quality of the urea is 20 g; 2) weigh a small amount of citric acid and evenly disperse it into the crucible. Step 1) In the weighed urea, the mass of citric acid is 20 mg; 3) Cover the crucible in step 2, place it in a muffle furnace, calcine at 550° C. for 4 hours, and then obtain nitrogen-doped carbon. / carbon nitride photocatalyst material, denoted as CN-20.

Embodiment 2

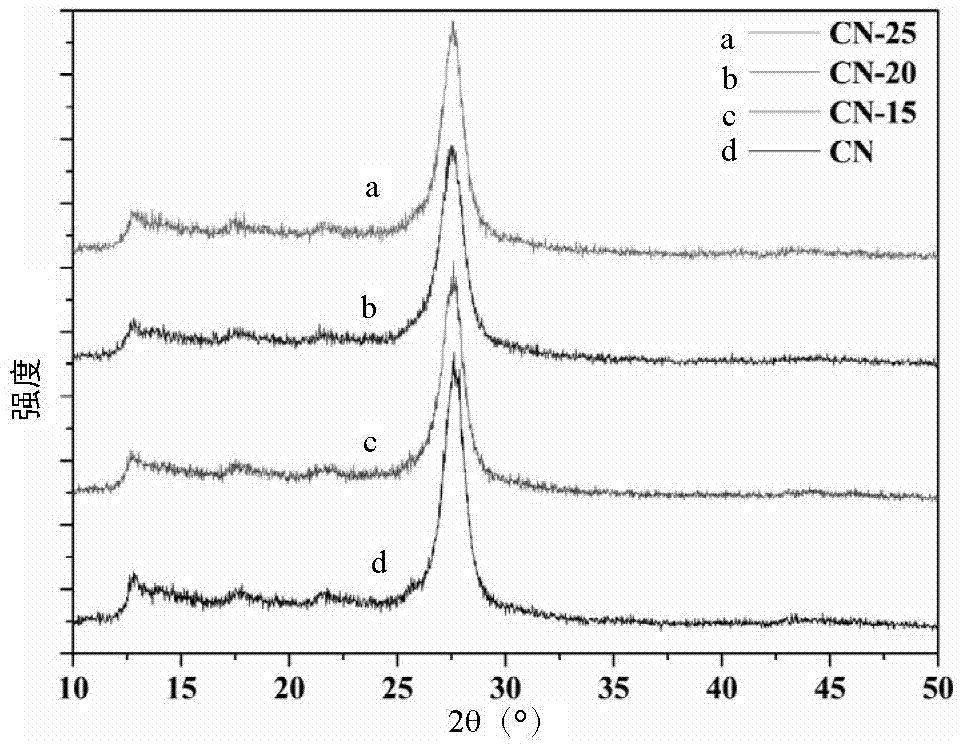

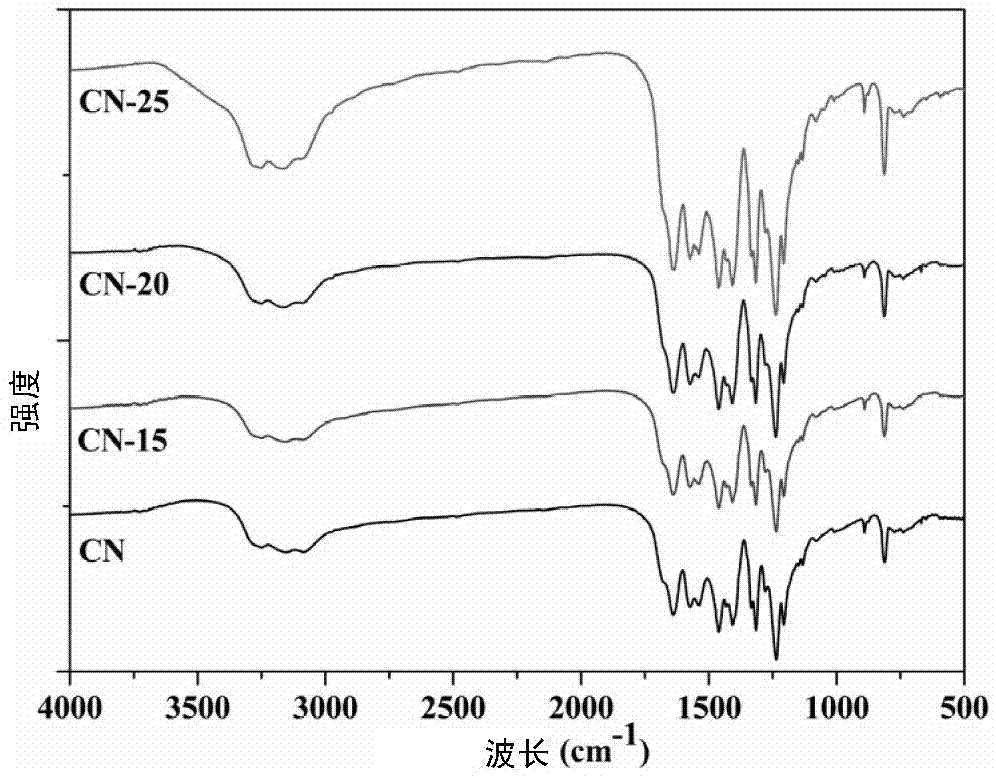

[0034] In order to examine the effect of different citric acid additions on the photocatalytic performance of nitrogen-doped carbon / carbon nitride photocatalysts, except for the different additions of citric acid, other reaction conditions such as urea addition (20 g), calcination temperature (550 °C), The holding time (4h) and the like are all the same as those in Example 1. The results show that when the amount of citric acid added is 0 mg (denoted as CN), that is, pure carbon nitride, the average photocatalytic hydrogen production is 14.5 umol h -1 ; When the amount of citric acid added was 15mg (denoted as CN-15), the average photocatalytic hydrogen production was 44.9umol h -1 ; When the amount of citric acid added was 25mg (denoted as CN-25), its average photocatalytic hydrogen production was 39.3umol h -1And in embodiment 1, when the addition amount of citric acid is 20mg, its average photocatalytic hydrogen production is 63.7umol h -1 . This indicates that the addit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com