Continuous preparation of carbon nanotube macroscopic body, and film forming method and apparatus

A carbon nanotube film and technology of carbon nanotubes, applied in the field of nanomaterials, can solve the problems that cannot meet the needs of industrialization, the size of the film is limited, and it is unfavorable for industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

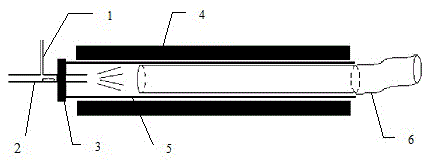

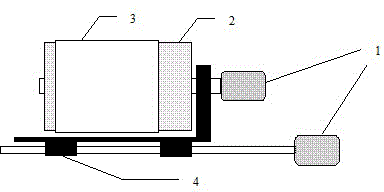

Embodiment 1

[0029] Using xylene as carbon source, ferrocene as catalyst, and thiophene as growth promoter, the mass fractions were 99.01%, 0.37%, and 0.62%, respectively, to prepare the reaction solution. The reactor is a high-temperature tube furnace, and the furnace tube is a corundum tube with a diameter of 10 mm. Raise the temperature of the reaction furnace to 1200°C, and feed nitrogen gas with a flow rate of 10 sccm. After the air in the furnace is exhausted, use an infusion pump to press the reaction solution into the quartz tube at a speed of 0.1 sccm, and enter the reaction furnace with nitrogen after being vaporized. , a high-temperature catalytic cracking reaction occurs, and carbon nanotubes are prepared and assembled into a cylindrical carbon nanotube macroscopic body, which is continuously blown out of the furnace tube with the gas at a speed of 1.2m / min. The macroscopic tube is gray, translucent, and has a diameter comparable to that of the furnace tube. For the spinning p...

Embodiment 2

[0032] The preparation process of carbon tubes and macroscopic tubes is the same as in Example 1, using n-hexane as the carbon source, ferrocene as the catalyst, and thiophene as the growth promoter, and the mass fractions are 99.01%, 0.37%, and 0.62% respectively to prepare the reaction solution. The reactor is a high-temperature tube furnace, and the furnace tube is a corundum tube with a diameter of 30 mm. Raise the temperature of the reaction furnace to 1800°C, and feed argon gas with a flow rate of 300 sccm. After the air in the furnace is exhausted, use an infusion pump to press the reaction solution into the quartz tube at a speed of 2 sccm, and enter the reaction with the argon gas after vaporization In the furnace, a high-temperature catalytic cracking reaction occurs, and carbon nanotubes are prepared and assembled into a cylindrical carbon nanotube macroscopic body, which is continuously blown out from the furnace tube at a speed of 50m / min with the gas. The macrosc...

Embodiment 3

[0036] The carbon tube macroscopic tube preparation process is the same as in Example 1, with n-hexane and acetone as the mixed carbon source, ferrocene as the catalyst, and thiophene as the growth promoter, and the mass fractions are 99.01%, 0.37%, and 0.62% respectively to prepare the reaction solution. The reactor is a high-temperature tube furnace, and the furnace tube is a corundum tube with a diameter of 60 mm. Raise the temperature of the reaction furnace to 1500°C, and feed helium gas with a flow rate of 1000 sccm. After the air in the furnace is exhausted, use an infusion pump to press the reaction solution into the quartz tube at a speed of 10 sccm, and enter the reaction with the helium after gasification In the furnace, a high-temperature catalytic cracking reaction occurs, and carbon nanotubes are prepared and assembled into a cylindrical carbon nanotube macroscopic body, which is continuously blown out from the furnace tube at a speed of 4.2m / min with the gas. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com