Method for preparing tea polysaccharides by combining separating membranes with chromatographic column

A technology for separating membranes and tea polysaccharides, applied in sustainable manufacturing/processing, chemical industry, climate sustainability, etc., can solve problems such as hidden dangers of product safety, cumbersome procedures, cumbersome separation processes, etc., to reduce production costs and be widely used. Prospects, the effect of improving the concentration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

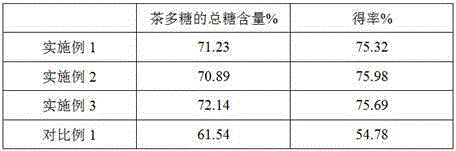

Examples

Embodiment 1

[0025] (1) After crushing the fresh tea leaves, add 10 times the mass of water or ethanol with a concentration of 70% to reflux for extraction for 2 hours, repeat once, filter the combined extract, and then concentrate to obtain the extract;

[0026] (2) Pass 100 kg of the extract obtained in step (1) through a separation membrane with a molecular weight of 50,000 Da until the solid content of the retentate is 15%, to obtain retentate I and permeate I;

[0027] (3) Pass the permeate I obtained in step (2) through a separation membrane with a molecular weight of 5000Da until the solid content of the retentate is 15%, to obtain the retentate II, combine the retentate I and the retentate II, and then mix the retentate Add 2 times the amount of purified water, then pass through a molecular weight 5000Da separation membrane for separation, repeat three times, and combine the retentate to obtain retentate III;

[0028] (4) Adjust the pH of the retentate III obtained in step (3) to 4...

Embodiment 2

[0031] (1) After crushing the fresh tea leaves, add 10 times the mass of water or 80% ethanol to reflux for extraction for 2 hours, repeat twice, filter the combined extract, and then concentrate to obtain the extract;

[0032] (2) Pass 100 kg of the extract obtained in step (1) through a separation membrane with a molecular weight of 50,000 Da until the solid content of the retentate is 20%, to obtain retentate I and permeate I;

[0033] (3) Pass the permeate I obtained in step (2) through a separation membrane with a molecular weight of 5000Da until the solid content of the retentate is 20% to obtain the retentate II, combine the retentate I and the retentate II, and then mix the retentate Add 2 times the amount of purified water, then pass through a molecular weight 5000Da separation membrane for separation, repeat three times, and combine the retentate to obtain retentate III;

[0034] (4) Adjust the pH of the retentate III obtained in step (3) to 4.5 with tartaric acid, t...

Embodiment 3

[0037] (1) After crushing the fresh tea leaves, add 10 times the mass of water or 90% ethanol to reflux for extraction for 2 hours, repeat 3 times, filter the combined extract, and then concentrate to obtain the extract;

[0038] (2) Pass 100 kg of the extract obtained in step (1) through a separation membrane with a molecular weight of 50,000 Da until the solid content of the retentate is 25%, to obtain retentate I and permeate I;

[0039] (3) Pass the permeate I obtained in step (2) through a separation membrane with a molecular weight of 5000Da until the solid content of the retentate is 25%, and then obtain the retentate II, combine the retentate I and the retentate II, and then mix the retentate in the mixed retentate Add 2 times the amount of purified water, then pass through a molecular weight 5000Da separation membrane for separation, repeat three times, and combine the retentate to obtain retentate III;

[0040] (4) Adjust the pH of the retentate III obtained in step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com