Flexible nanocarbon/zinc oxide monochromatic ultraviolet fluorescence film and preparation method and application thereof

A nano-carbon and zinc oxide technology, applied in chemical instruments and methods, luminescent materials, gaseous chemical plating, etc., to achieve low cost, mass production, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

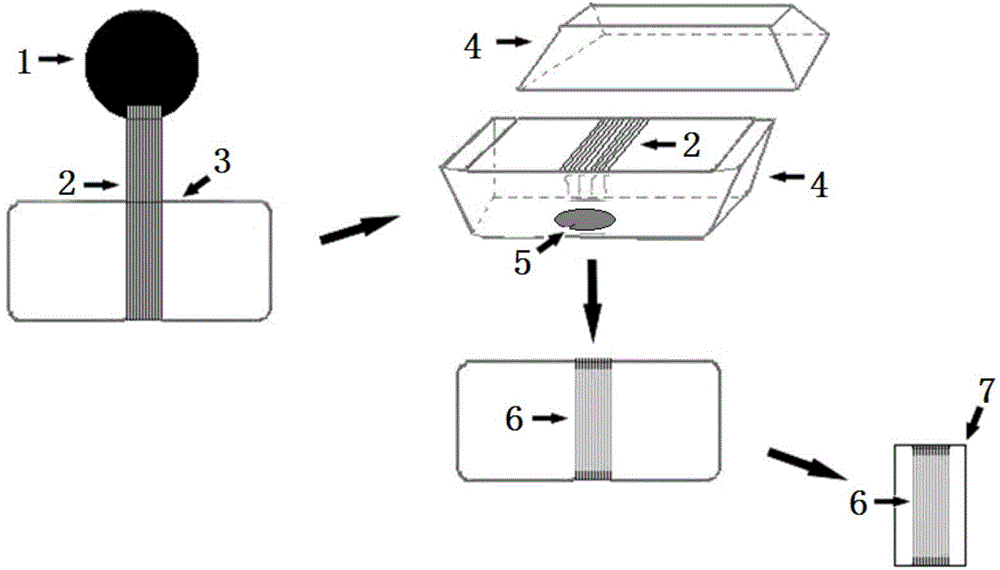

[0084] Example 1 The preparation process of the flexible carbon nanotube / zinc oxide monochromatic ultraviolet fluorescent film comprises the following steps:

[0085] Step 1: Pull out a carbon tube film with a width of about 1.7 cm and a length of about 3 cm from the spinnable array and put it on the copper frame.

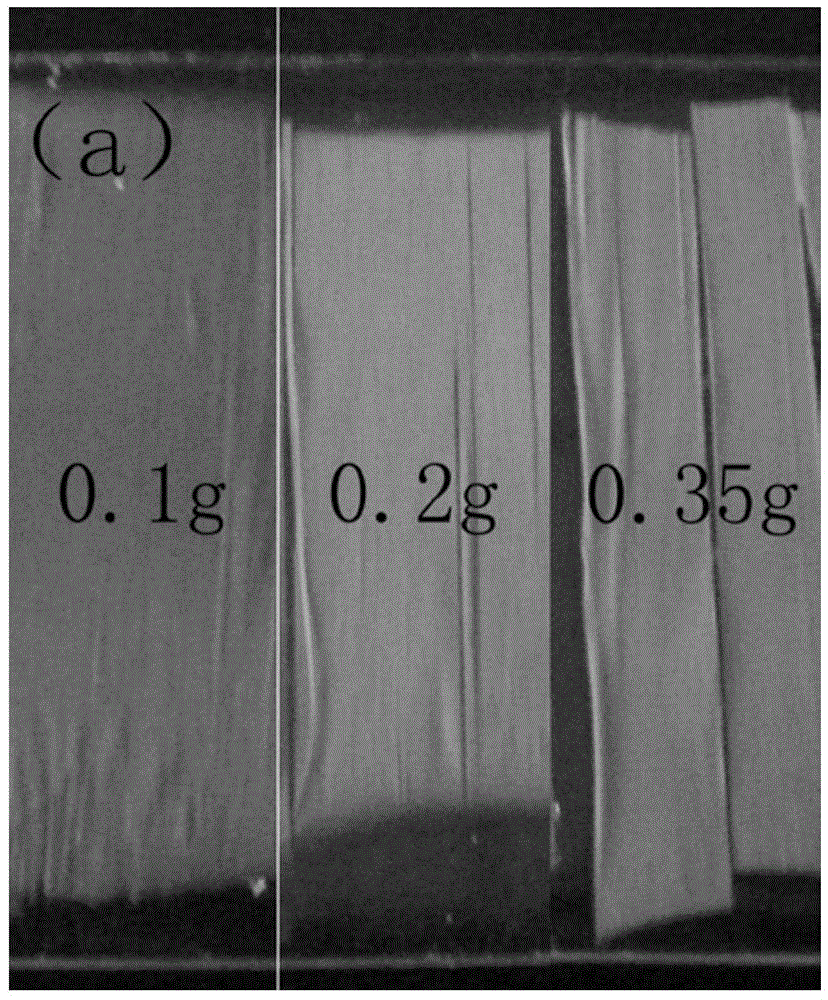

[0086] Step 2: Weigh 0.1g of zinc acetylacetonate and lay it on the porcelain boat, so that the width of the laying is basically equivalent to the width of the two carbon tube films. The edge basically coincides with the wide edge of the precursor tile, and the film as a whole is located directly above the precursor, and it is covered with another porcelain boat of the same size, with a gap of about 3mm.

[0087] Step 3 Place the whole object obtained in step 2 in the heating center of the quartz glass tube of the horizontal tube furnace, with both ends of the tube open. Start from room temperature and heat at a rate of 7°C / min. When the temperature rises to 17...

Embodiment 2

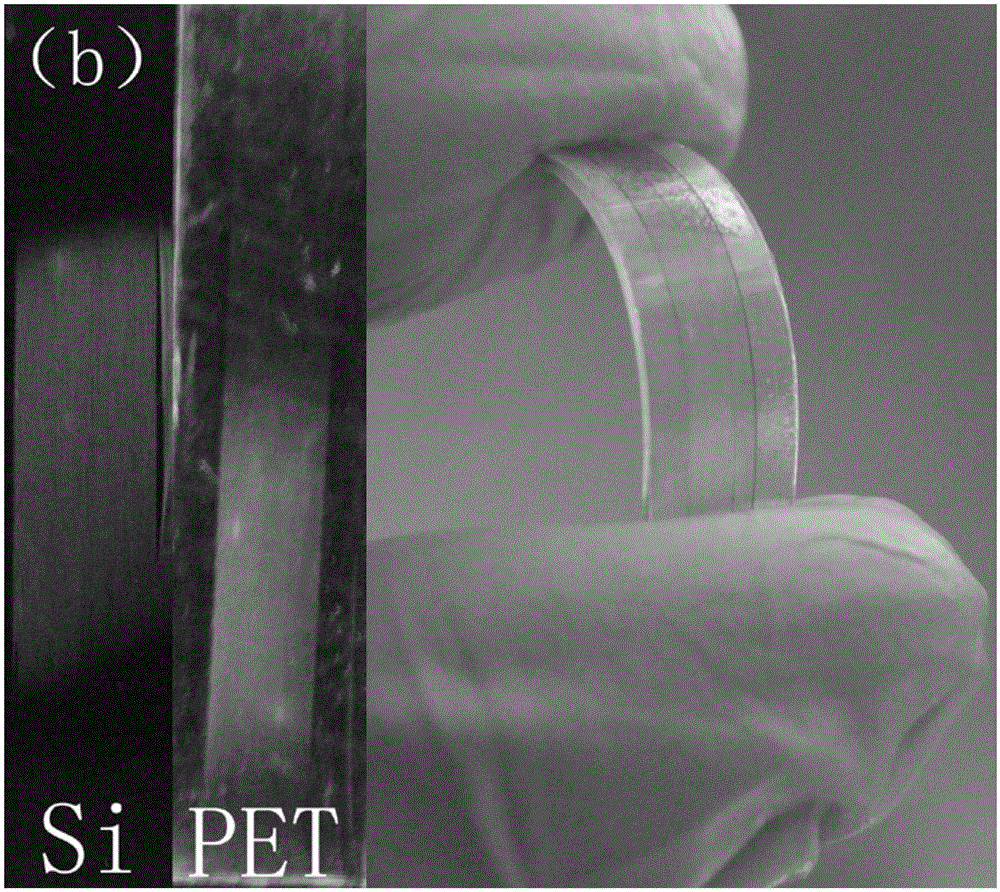

[0092] Example 2 This implementation will list as an extension of the preparation process of the flexible carbon nanotube / zinc oxide monochromatic ultraviolet fluorescent film material, and introduce the self-supported graphene oxide-zinc oxide nanoparticle composite film on the fire-resistant mosquito net with grid The preparation process comprises the following steps:

[0093]Step 1: Immerse the fire-resistant and anti-mosquito screen curtain cloth in the pre-prepared aqueous dispersion of graphene oxide with a concentration of 2mg / ml for 1min, then take it out and dry it in an oven at 60°C to form a self-supporting oxidized layer on the grid. Graphene film screen cloth.

[0094] Step 2: Place the screen cloth with graphene oxide film distributed on the grid in step 1 horizontally on the porcelain boat with 0.1g zinc acetylacetonate precursor, so that the grid with self-supporting graphene oxide film distribution Located directly above the precursor, cover it with another...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com