A fluorescent chemical sensor for detecting sodium dithionite and its preparation method and application

A sodium dithionite and chemical sensor technology, which is applied in the field of fluorescent chemical sensors, can solve the problems of high price, long time consumption, and difficult operation, and achieve the effects of high sensitivity, good selectivity, and easy deviceization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1 A fluorescent chemical sensor for detecting sodium dithionite

[0036] A method for preparing a fluorescent chemical sensor for detecting sodium dithionite, comprising the following steps:

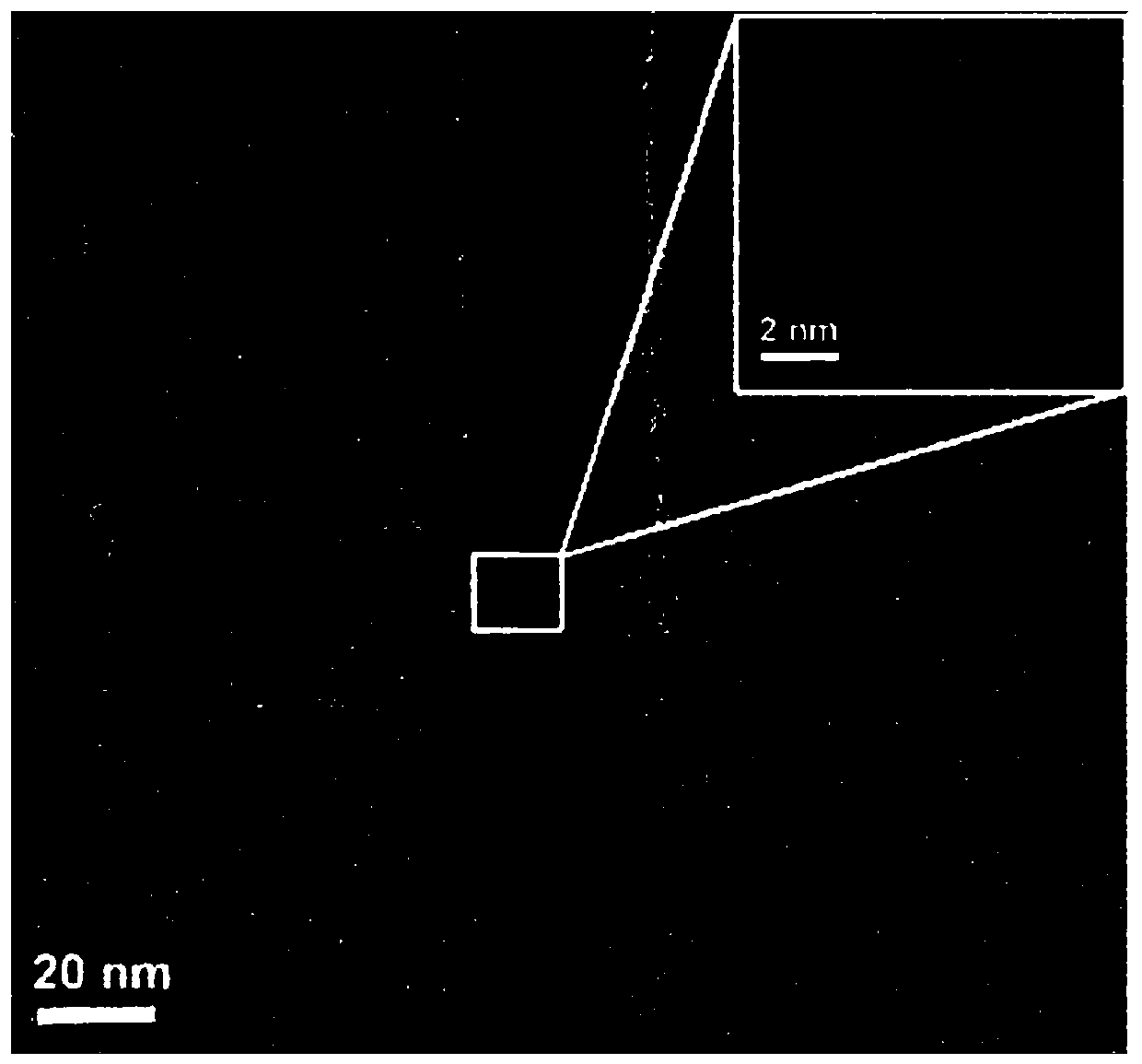

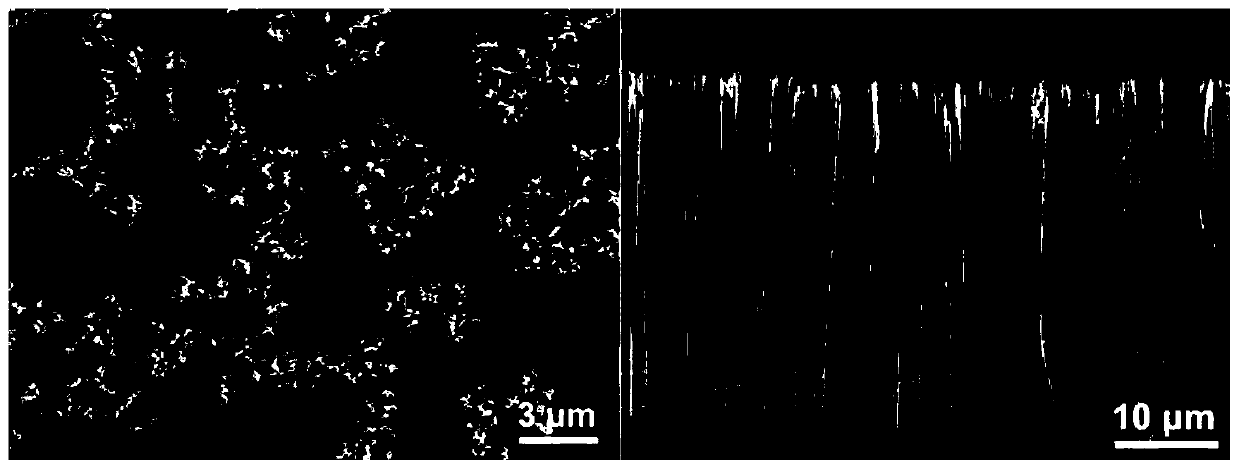

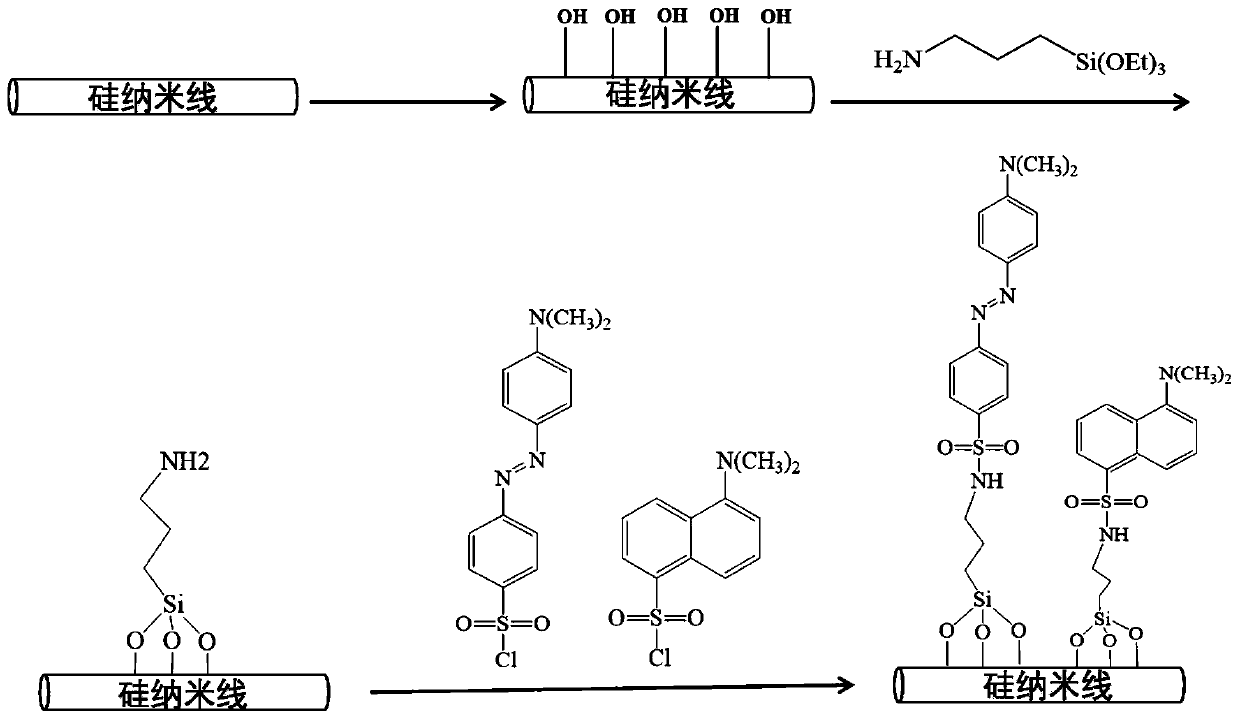

[0037] 1) At room temperature, silicon monoxide is put into a porcelain boat, and the porcelain boat is placed in the middle of the quartz tube of the horizontal tube furnace, then the system is first vacuumed to 10Pa with a mechanical pump and a molecular pump, and then the vacuum is evacuated to 10Pa with a 20sccm ( mL / min) into the mixed gas of argon (85%) and hydrogen (15%), repeated pumping and ventilating three times, when the pressure rose above 800Pa, the system began to heat up. The system was raised to 800°C at 10°C / min, kept for 30 minutes, then continued to rise to 1350°C, adjusted the pressure so that the system pressure was at 1300Pa, and closed the mechanical pump and the intake valve. After reacting under this condition for 7 hours, the heating was stopped...

Embodiment 2

[0042] Example 2 A fluorescent chemical sensor for detecting sodium dithionite

[0043] A method for preparing a fluorescent chemical sensor for detecting sodium dithionite, comprising the following steps:

[0044] 1) At room temperature, silicon monoxide is put into a porcelain boat, and the porcelain boat is placed in the middle of the quartz tube of the horizontal tube furnace, then the system is first vacuumed to 10Pa with a mechanical pump and a molecular pump, and then the vacuum is evacuated to 10Pa with a 24sccm ( mL / min) into the mixed gas of argon (85%) and hydrogen (15%), repeated pumping and ventilation three times, when the pressure rises above 1000Pa, the system starts to heat up. The system rises to 800°C at 12°C / min, keeps the temperature for 30 minutes, then continues to rise to 1350°C, adjusts the pressure so that the system pressure is 2000Pa, and closes the mechanical pump and the intake valve. After reacting under this condition for 5 hours, the heating w...

Embodiment 3

[0049] Example 3 A fluorescent chemical sensor for detecting sodium dithionite

[0050] A method for preparing a fluorescent chemical sensor for detecting sodium dithionite, comprising the following steps:

[0051] 1) At room temperature, silicon monoxide is put into a porcelain boat, and the porcelain boat is placed in the middle of the quartz tube of the horizontal tube furnace, then the system is first evacuated to 8Pa with a mechanical pump and a molecular pump, followed by 30sccm ( mL / min) into the mixed gas of argon (85%) and hydrogen (15%), repeated pumping and ventilation three times, when the pressure rises above 1300Pa, the system starts to heat up. The system is raised to 800°C at 16°C / min, kept for 20 minutes, then continues to rise to 1350°C, adjust the pressure so that the system pressure is at 2000Pa, close the mechanical pump and the intake valve. After reacting under this condition for 5 hours, the heating was stopped, and it was naturally cooled to room temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com