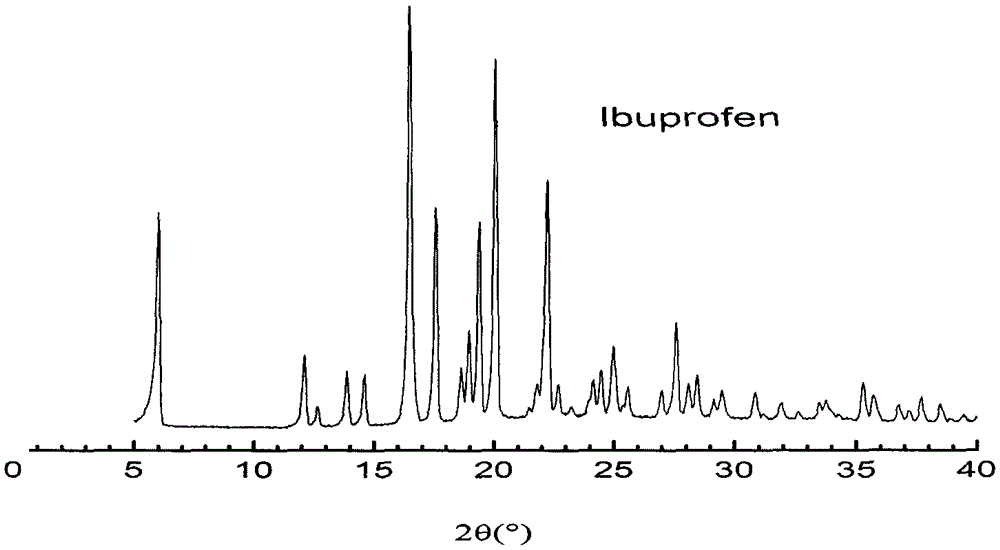

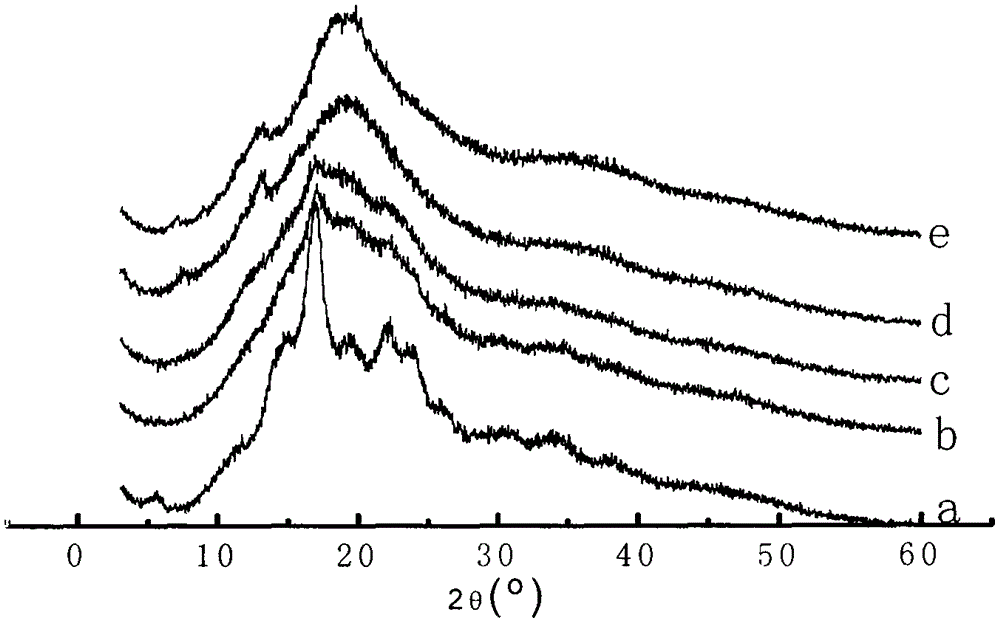

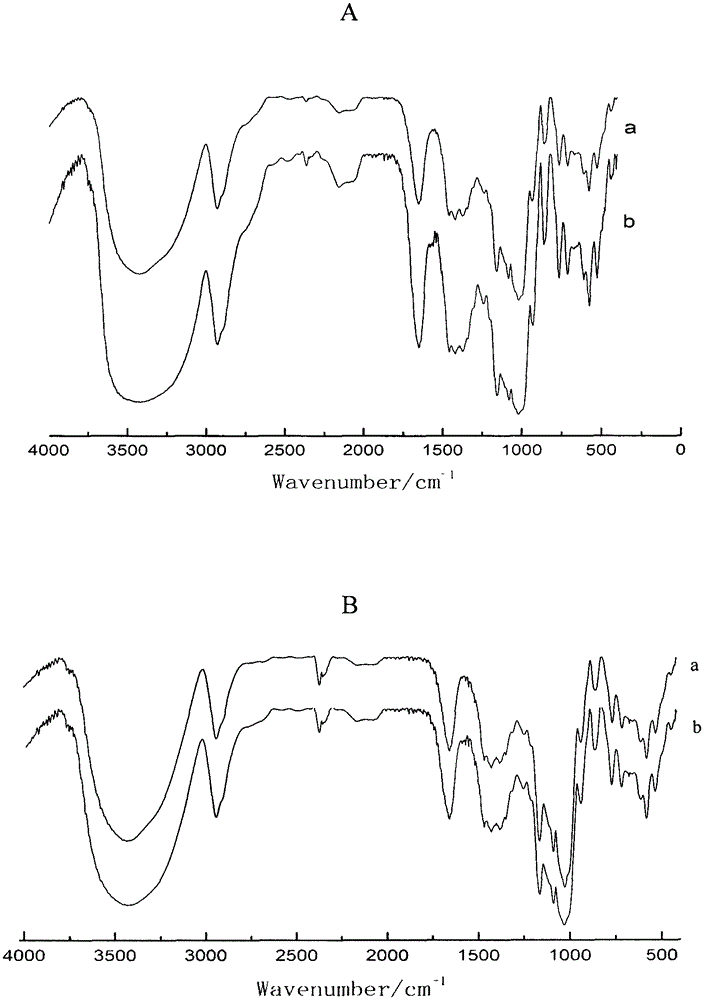

In-situ preparation method for starch-ibuprofen clathrate compound of V-type crystal structure

A technology of in-situ preparation and crystalline structure, applied in the directions of pharmaceutical formulation, drug combination, drug delivery, etc., can solve the problems of high price of β-cyclodextrin, limited application range, poor starch emulsification, etc., and achieves low cost and simplification. The preparation process and the effect of high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] a. Accurately weigh a certain amount of ibuprofen (the ratio of ibuprofen and starch is 1:4) and add it to the ethanol solution with a dilution of 70%, stir to make it completely dissolve, then add a certain amount of potato starch to adjust The concentration is 70g / L starch milk, put it into a constant temperature stirrer and keep it at 45°C, and keep stirring;

[0025] b. Add a certain amount of 8mL3mol / L NaOH dropwise into the starch milk at a constant speed of 4mL / min. After the dropwise addition, stir at constant temperature for 60min to make it fully react;

[0026] c. After the reaction is completed, the starch milk is suction-filtered, and the filter cake is dispersed with 60% ethanol solution 20 times the weight of the starch, and the pH is adjusted to 7.0 with 3% (V / V) hydrochloric acid-ethanol solution, and the suction filtration is continued to obtain the filter cake Wash 3 times with 95% ethanol, then wash 1 time with absolute ethanol;

[0027] d. The prod...

Embodiment 2

[0030] a. Accurately weigh a certain amount of ibuprofen (the ratio of ibuprofen and starch is 1:4) and add it to the ethanol solution with a dilution of 50%, stir to make it completely dissolve, then add a certain amount of potato starch to adjust The concentration is 80g / L starch milk, put it into a constant temperature stirrer and keep it at 50°C, and keep stirring;

[0031] b. Add a certain amount of 8mL3mol / L NaOH dropwise to the starch milk at a constant speed of 4mL / min. After the dropwise addition, stir at constant temperature for 40min to make it fully react;

[0032] c. After the reaction is completed, the starch milk is suction-filtered, and the filter cake is dispersed with 60% ethanol solution 20 times the weight of the starch, and the pH is adjusted to 7.0 with 3% (V / V) hydrochloric acid-ethanol solution, and the suction filtration is continued to obtain the filter cake Wash 3 times with 95% ethanol, then wash 1 time with absolute ethanol;

[0033] d. The produc...

Embodiment 3

[0036]a. Accurately weigh a certain amount of ibuprofen (the ratio of ibuprofen and starch is 1:4) and add it to the ethanol solution with a dilution of 50%, stir to make it completely dissolve, then add a certain amount of potato starch to adjust Starch milk with a concentration of 70g / L, put it in a constant temperature stirrer and keep it at 55°C, and keep stirring;

[0037] b. Add 12mL of 3mol / L NaOH dropwise to the starch milk at a constant speed of 4mL / min. After the dropwise addition, stir at constant temperature for 30min to make it fully react;

[0038] c. After the reaction is completed, the starch milk is suction-filtered, and the filter cake is dispersed with 60% ethanol solution 20 times the weight of the starch, and the pH is adjusted to 7.0 with 3% (V / V) hydrochloric acid-ethanol solution, and the suction filtration is continued to obtain the filter cake Wash 3 times with 95% ethanol, then wash 1 time with absolute ethanol;

[0039] d. The product obtained abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com