A kind of photocatalytic decomposition water hydrogen production solid solution catalyst and preparation method thereof

A technology of photocatalysis and water hydrogen production, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, hydrogen production, etc., can solve the problem of low efficiency of photocatalytic decomposition of water to produce hydrogen, meet the requirements of industrialization, improve separation efficiency, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

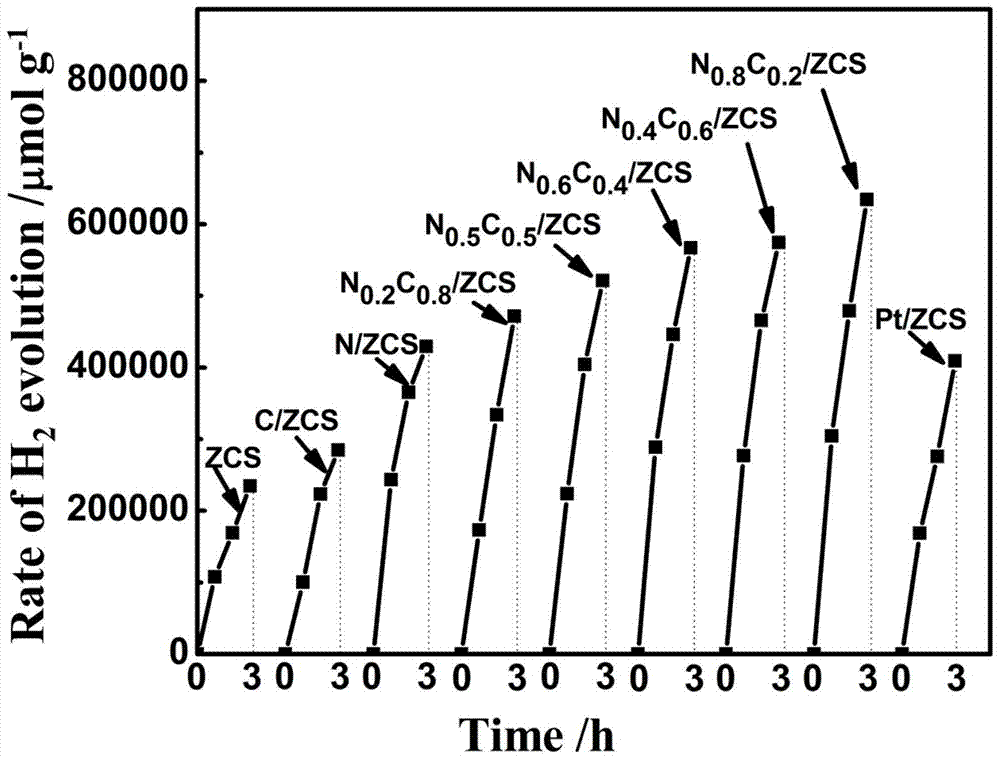

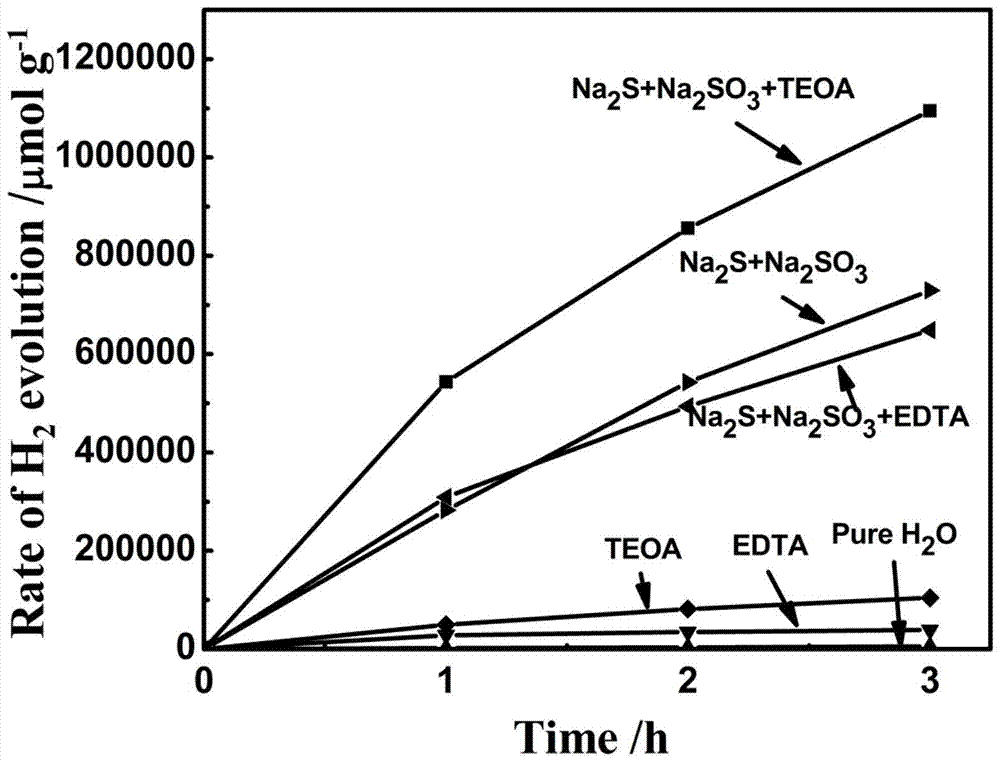

Examples

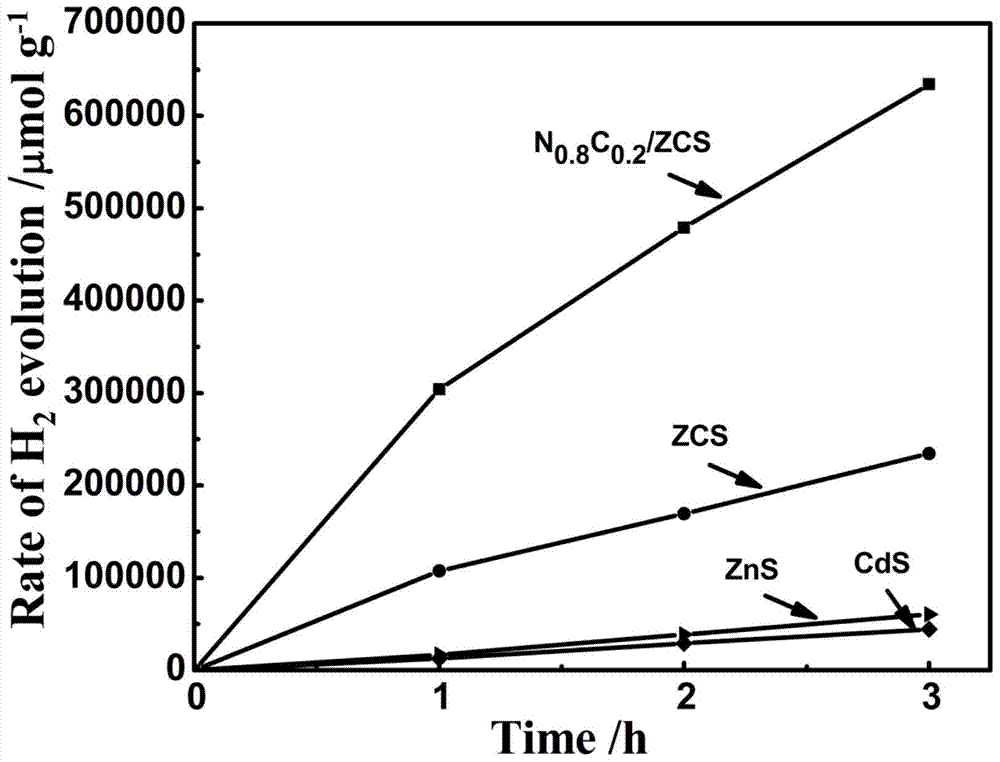

Embodiment 1

[0021] (1) get 0.404 gram of zinc acetate (purity=99.5%) and 0.106 gram of cadmium acetate (purity=99.5%) and put into 250 milliliters of beakers and stir 10 minutes together, then add the sodium sulfide of 0.829 gram under the stirring condition (purity=99.5%) 99.0%), continued stirring for 4 hours; then transferred to a reactor with polytetrafluoroethylene lining, the reactor was put into a 180-degree oven and reacted for 12 hours, then took out the reactor and allowed it to cool down naturally at room temperature;

[0022] (2) Wash and centrifuge the suspension obtained in step (1) reaction kettle with deionized water 4 times, then wash and centrifuge 2 times with ethanol (purity=99.9%), discard the supernatant and then place it under the condition of 80 degrees Celsius Dry for 12 hours; the product obtained after drying is the zinc cadmium sulfide solid solution Zn that we want to prepare. 0.75 Cd 0.25 S, detected as a pure phase zinc cadmium sulfide solid solution by X-r...

Embodiment 2

[0025] Steps (1)~(2) are with embodiment 1;

[0026] (3) Take the product obtained in step (2) and disperse it in 20 milliliters of deionized water under nitrogen protection, use an ultrasonic machine to sonicate for 30 minutes and then stir for 30 minutes, add 5 milliliters of 0.0046 mol / liter cobalt nitrate solution and continue to stir 2 hours;

[0027](4) Add 0.36 g of sodium borohydride (purity=99.5%) particles to step (3), then continue to stir for 5 hours, then wash and centrifuge 5 times with deionized water, then wash with ethanol (purity=99.9%) Centrifuge 2 times, discard the supernatant, and dry at 80 degrees Celsius for 12 hours to obtain a zinc-cadmium sulfide solid solution with elemental cobalt on the surface, which is the photocatalytic decomposition of water hydrogen production catalyst according to the present invention, that is, the mass of elemental cobalt accounts for 10% of the zinc-cadmium sulfide. The mass fraction of the solid solution is 1%, named: 1...

Embodiment 3

[0030] Steps (1)~(2) are with embodiment 1;

[0031] (3) Take the product obtained in step (2) and disperse it in 20 milliliters of deionized water under the protection of nitrogen, use an ultrasonic machine to sonicate for 30 minutes and then stir for 30 minutes. 2 hours;

[0032] (4) Add 0.36 g of sodium borohydride (purity=99.5%) particles to step (3), then continue to stir for 5 hours, then wash and centrifuge 5 times with deionized water, then wash with ethanol (purity=99.9%) Centrifuge 2 times, discard the supernatant, and dry at 80 degrees Celsius for 12 hours to obtain a zinc-cadmium sulfide solid solution with elemental nickel on the surface, which is the photocatalytic decomposition of water hydrogen production catalyst of the present invention, that is, the mass of elemental nickel accounts for 10% of the zinc-cadmium sulfide. The mass fraction of the solid solution is 1%, named: 1%Ni / Zn 0.75 Cd 0.25 S.

[0033] (5) the product in step (4) is mixed to form homog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com