Synthetic method of zsm‑5 molecular sieve with special morphology

A ZSM-5, morphology technology, applied in the direction of crystalline aluminosilicate zeolite, borocarbonane silicone crystalline aluminosilicate zeolite, etc., can solve the problem of not being able to obtain petal-shaped ZSM-5 zeolite, and achieve good practicality. performance and effectiveness, lower synthesis costs, and the effect of good parallelism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Synthesis method: add 1.7g of sodium hydroxide solution with a mass fraction of 40%, 1g of sodium fluoride, 0.38g of n-propylamine, 1.6g of hexamethylenetetramine, and 0.051g of aluminum sulfate octadecahydrate into 15g of water, stir well, and then add 5 g of silica sol with a mass fraction of 40% was stirred for 30 min, and the gel was aged for 8 h at room temperature. After that, it was crystallized at 180°C and stirred at 150rpm for 5 days, cooled to room temperature, washed with deionized water and centrifuged three times, and dried at 80°C for 12 hours to obtain the final product.

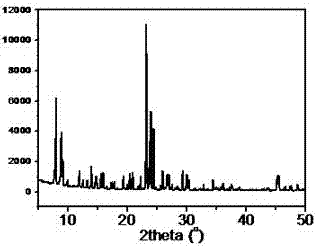

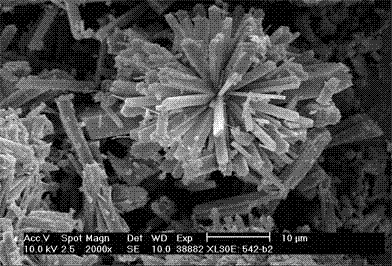

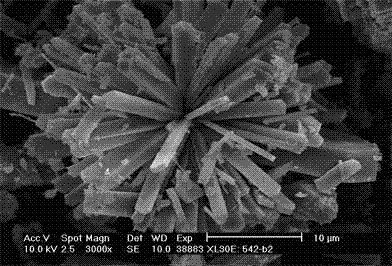

[0030] figure 1 It is the XRD spectrogram of the product obtained in Example 1, it can be seen that the product has the characteristic diffraction peak of ZSM-5, and has a higher crystallinity. figure 2 , image 3 It is the SEM photo of the product obtained in Example 1 with different magnifications. It can be seen that the sample presents a special petal-shaped appearance, and the ...

Embodiment 2

[0032] Using the same conditions as in Example 1, changing the amount of n-propylamine to 4.2g, to obtain the final product. According to the XRD characterization results of the sample, it can be seen that the product has the characteristic diffraction peak of ZSM-5, and the SEM photo shows that the sample has a petal-shaped morphology.

Embodiment 3

[0034] Using the same conditions as in Example 1, changing the water consumption is 8g, and the n-propylamine consumption is 1.8g to obtain the final product. According to the XRD characterization results of the sample, it can be seen that the product has the characteristic diffraction peak of ZSM-5, and the SEM photo shows that the sample has a petal-shaped morphology.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com