A kind of coagulant for strengthening treatment of chemical sewage and its preparation method and use

A technology for intensive treatment of chemical sewage, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of unqualified effluent water quality, unstable sewage quality, high operating costs, etc., and achieve the effect of low price, easy operation, and wide range of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

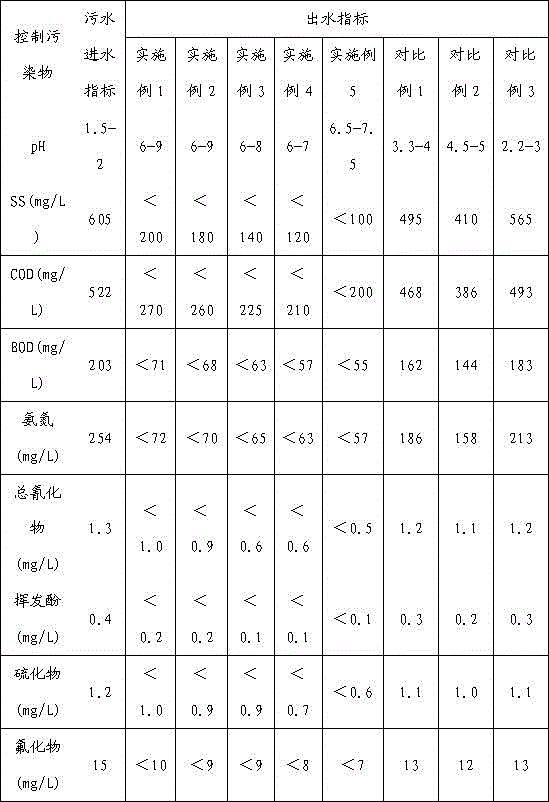

Examples

Embodiment 1

[0019] In Example 1 of the present invention, a coagulant for enhanced treatment of chemical sewage is composed of the following raw materials in parts by weight: 37 parts of montmorillonite, 18 parts of split wood, 48 parts of dimethylformamide, sodium polyacrylate 3 parts, 10 parts of disodium edetate.

[0020] Grind the split wood into powder, and pass through a 200-mesh sieve to make the split wood powder. At a stirring speed of 160r / min, mix the split wood powder with half the weight of dimethylformamide, and heat to 75°C. And keep it at this temperature for 30 minutes, and then carry out the first stage of ultrasonic treatment, the ultrasonic treatment time is 1 hour, the ultrasonic power is 900W, and the ultrasonic temperature is 90°C to obtain the first ultrasonic liquid. At a stirring speed of 160r / min, add sodium polyacrylate and the other half of the weight part of dimethylformamide into the first ultrasonic liquid, heat to 100°C, and keep at this temperature for 30...

Embodiment 2

[0022] In Example 2 of the present invention, a coagulant for enhanced treatment of chemical sewage is composed of the following raw materials in parts by weight: 46 parts of montmorillonite, 25 parts of split wood, 55 parts of dimethylformamide, sodium polyacrylate 8 parts, 15 parts of disodium edetate.

[0023] Grind the split wood into powder, and pass through a 200-mesh sieve to make the split wood powder. At a stirring speed of 200r / min, mix the split wood powder with half the weight of dimethylformamide, and heat to 85°C. And keep at this temperature for 50 minutes, and then carry out the first stage of ultrasonic treatment, the ultrasonic treatment time is 1.5 hours, the ultrasonic power is 900W, and the ultrasonic temperature is 95°C to obtain the first ultrasonic liquid. At a stirring speed of 200r / min, add sodium polyacrylate and the other half of the weight part of dimethylformamide into the first ultrasonic liquid, heat to 110°C, and keep at this temperature for 50...

Embodiment 3

[0025] In Example 3 of the present invention, a coagulant for enhanced treatment of chemical sewage is composed of the following raw materials in parts by weight: 40 parts of montmorillonite, 19 parts of heartwood, 50 parts of dimethylformamide, sodium polyacrylate 5 parts, 11 parts of disodium edetate.

[0026] Grind the split wood into powder, and pass through a 200-mesh sieve to make the split wood powder. At a stirring speed of 180r / min, mix the split wood powder with half the weight of dimethylformamide, and heat to 80°C. And keep at this temperature for 40 minutes, and then carry out the first stage of ultrasonic treatment, the ultrasonic treatment time is 1.2 hours, the ultrasonic power is 900W, the ultrasonic temperature is 92°C, and the first ultrasonic liquid is obtained. At a stirring speed of 180r / min, add sodium polyacrylate and the other half of the weight part of dimethylformamide into the first ultrasonic liquid, heat to 105°C, and keep at this temperature for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com