Synthesis and surface modification of polyglycidyl methacrylate microspheres

A technology of polymethacrylic acid and glycidol, which is applied in the field of surface modification of solid-phase carriers, can solve problems such as inconvenient operation and environmental pollution, and achieve the effects of simple operation, simple post-processing operation, and low reaction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

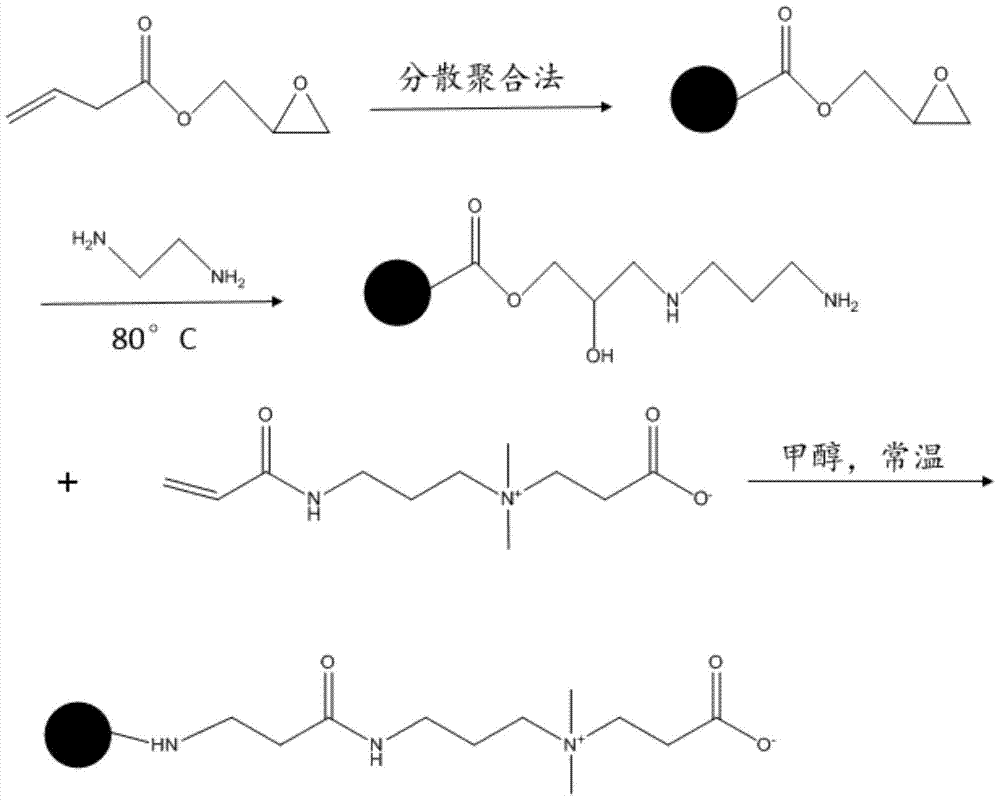

Method used

Image

Examples

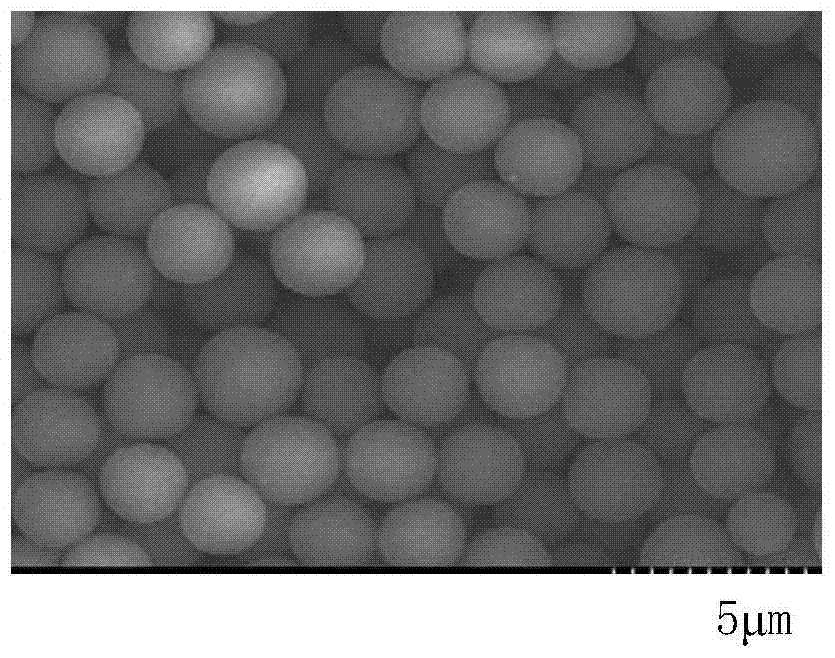

Embodiment 1

[0034] (1) Weigh 0.5 g of polyvinylpyrrolidone (PVP), dissolve it in 20 mL of 8.5:1 mixed solvent of ethanol and water, and transfer it to a four-neck flask after dissolving.

[0035] (2) Weigh 0.05 g of azobisisobutyronitrile (AIBN) and 2.5 g of glycidyl methacrylate (GMA) monomers, and transfer them to a four-neck flask after ultrasonic dissolution.

[0036] (3) After ultrasonicating the four-neck flask for 10 min, one mouth of the four-necked flask was sealed with a rubber stopper, one was connected to a vacuum line tube for vacuuming and nitrogen filling, the other was connected to a reflux condenser, and the middle mouth was used to fix a stirring rod. After the installation is completed, vacuumize, fill with nitrogen, repeat several times, and reflux and condense in a water bath at 72°C for more than 8 hours at a stirring speed of 180r / min.

[0037] (4) After the reaction, the white emulsion in the four-neck flask was taken out, centrifuged to remove the supernatant, and...

Embodiment 2

[0040] 1) Weigh 1 g of the white solid powder of PGMA microspheres obtained in Example 1 into a 100 mL flask, add 20 mL of water and 30 mL of ethylenediamine.

[0041] 2) A reflux condenser was connected to the mouth of the flask, and the reaction was carried out with magnetic stirring for 12 hours in a water bath at 80°C.

[0042] 3) After the reaction is over, transfer the white emulsion to a centrifuge tube and centrifuge to remove the supernatant, then centrifuge and wash with deionized water for more than 3 times. Finally, the supernatant was removed, and the white precipitate was vacuum-dried to obtain PGMA-NH 2 Microsphere white solid powder.

[0043] From image 3 It can be seen that the PGMA-NH2 microspheres obtained by this method have very little morphology damage, and still keep well dispersed microspheres; from Figure 5 It can be seen from the infrared spectrum that after ethylenediamine treats PGMA microspheres, the characteristic absorption peak of the epoxy...

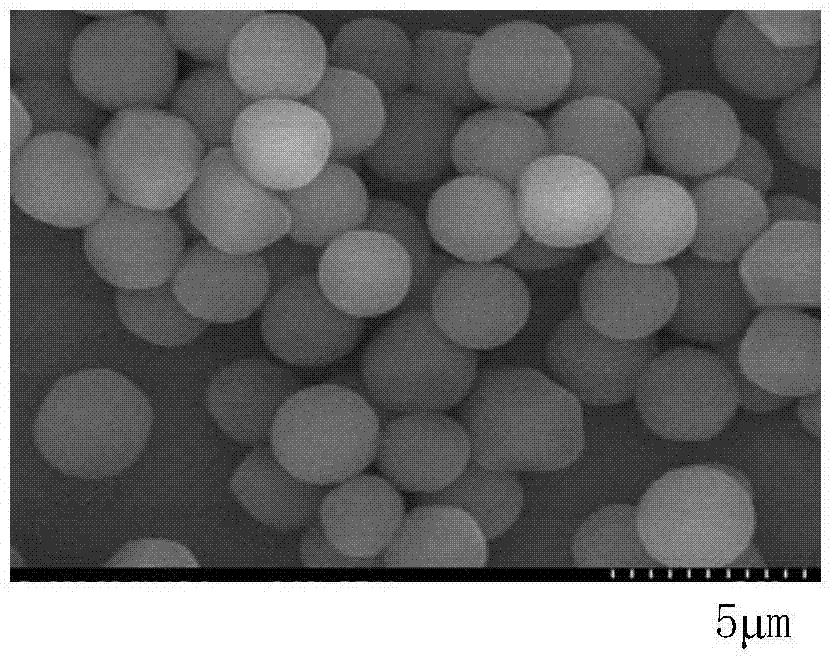

Embodiment 3

[0045] 1) Weigh 0.4 g of the PGMA-NH microspheres obtained in Example 2 in a 25 mL round bottom flask, add 0.16 g of carboxybetaine (CBAA) and 12 mL of methanol solvent.

[0046] 2) Stir with magnetic force and react at room temperature for 3 days.

[0047] 3) After the reaction, transfer the white emulsion to a centrifuge tube, centrifuge to remove the supernatant, and wash with deionized water by centrifugation, repeating more than 3 times. Finally, the supernatant was removed, and the white precipitate was vacuum-dried to obtain PGMA-NH2-CBAA microspheres.

[0048] From Figure 4 It can be seen that the PGMA-NH obtained by this method 2 -CBAA microspheres, the shape is very small, and the microspheres are still well dispersed and uniform; from Figure 5 It can be seen from the infrared spectrum that after the Michael addition reaction between PGMA-NH2 and carboxybetaine, the microspheres appeared the –C(=O)-N(-H)-characteristic peak of CBAA, indicating that CBAA was on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com