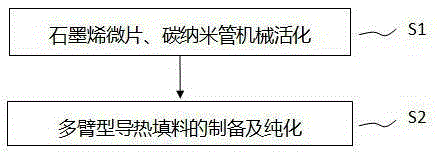

Preparation method of graphene oxide/carbon nanotube multi-arm heat conducting filler

A technology of carbon nanotubes and thermally conductive fillers is applied in the preparation of graphene/carbon nanotube multi-arm thermally conductive fillers, and the preparation of graphene oxide and carbon nanotube multi-armed thermally conductive fillers, which can solve the problem of hybridization efficiency. Low, unstable processing and other problems, to achieve the effect of improving dispersion performance, improving thermal conductivity, and expanding applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

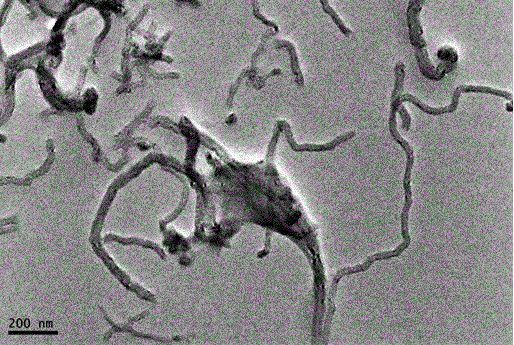

[0030] Graphene microchips are placed in a polytetrafluoroethylene ball milling jar, and silicon carbide ball milling balls with a particle size of 0.5, 1 and 2 mm are selected. The ratio is 1:0.6:0.2, and the ball milling ball accounts for 40% of the ball milling jar volume. Add A certain volume of concentrated sulfuric acid was ball milled at a speed of 400 rpm for 12 hours. During ball milling, ice water was introduced into the outer wall of the ball mill tank, and the cooling water was changed every 3 hours to obtain mechanically exfoliated graphene oxide.

[0031]Put carbon nanotubes with an aspect ratio of 80:1 and a tube diameter of 20nm into a polytetrafluoroethylene ball mill jar, and select silicon carbide balls with a particle size of 0.5, 1 and 2 mm, and the ratio is 1:0.8:0.05 , the balls account for 20% of the volume of the ball milling tank, add a certain volume of isopropyl tris (dioctyl pyrophosphate acyloxy) titanate in isopropanol solution, wherein isopropyl ...

Embodiment 2

[0034] Graphene microchips are placed in a polytetrafluoroethylene ball mill jar, select boron nitride ball mill balls with a particle size of 0.5, 1 and 2 mm, and the ratio is 1:0.8:0.05, and the ball mill ball accounts for 60% of the ball mill jar volume, Add a certain volume of nitric acid, and ball mill at a speed of 2000 rpm for 24 hours. During ball milling, ice water is introduced into the outer wall of the ball mill tank, and the cooling water is changed every 3 hours to obtain mechanically exfoliated graphene oxide.

[0035] Put carbon nanotubes with an aspect ratio of 200:1 and a tube diameter of 10nm into a polytetrafluoroethylene ball mill jar, and select silicon carbide balls with a particle size of 0.5, 1 and 2 mm, and the ratio is 1:0.6:0.2 , the milling ball accounts for 40% of the volume of the ball milling tank, and a certain volume of isopropyl tris (dioctyl phosphate acyloxy) titanate isopropanol solution is added, wherein isopropyl tris (dioctyl phosphate a...

Embodiment 3

[0038] Graphene microchips are placed in a polytetrafluoroethylene ball milling jar, and silicon carbide ball milling balls with a particle size of 0.5, 1 and 2 mm are selected. The ratio is 1:0.7:0.1, and the ball milling ball accounts for 50% of the ball milling jar volume. Add A certain volume of perchloric acid was ball milled at a speed of 600 rpm for 16 hours. During ball milling, ice water was introduced into the outer wall of the ball mill tank, and the cooling water was changed every 3 hours to obtain mechanically exfoliated graphene oxide.

[0039] Put the carbon nanotubes with an aspect ratio of 100:1 and a tube diameter of 40nm into a polytetrafluoroethylene ball mill jar, and select silicon carbide balls with a particle size of 0.5, 1 and 2 mm, and the ratio is 1:0.6:0.15 , the ball milling ball accounts for 30% of the volume of the ball milling tank, add a certain volume of isopropyl dioleate (dioctyl phosphate acyloxy) titanate in isopropanol solution, wherein is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com