A kind of acrylate rubber accelerator pre-dispersed masterbatch and preparation method thereof

A technology of pre-dispersed masterbatches and acrylates, applied in the field of rubber additives, can solve problems such as difficulty in mixing into rubber, low vulcanization characteristics, and difficulty in metering, to optimize scorch time, improve vulcanization efficiency, and improve low compression set. and the effect of aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

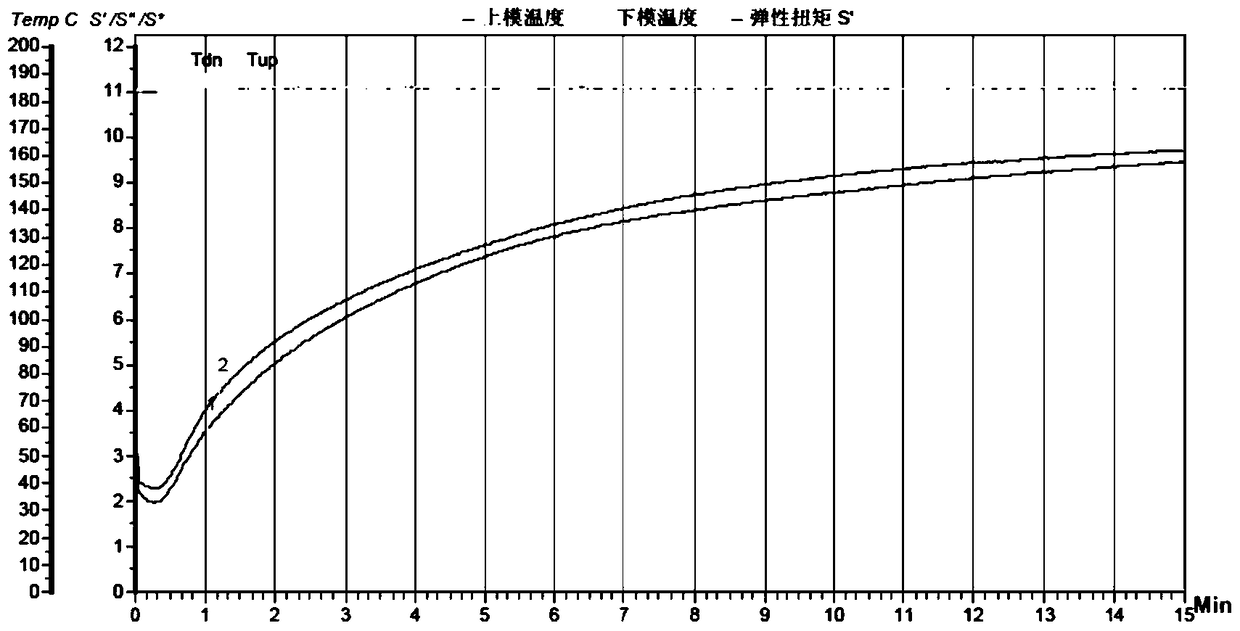

Image

Examples

Embodiment 1

[0040] Acrylic rubber accelerator pre-dispersed masterbatch ACT-70-1, based on 100 parts by total weight, its components and parts by weight are as follows:

[0041] 28 parts of acrylate rubber, 19 parts of zinc diisobutylthiophosphate, 23 parts of 2,5-diazabicyclo[2.2.1]heptane, 24 parts of white carbon black, 5.7 parts of paraffinic process oil, talc Powder 0.3 part.

[0042] The preparation method of above-mentioned acrylate rubber accelerator pre-dispersed master batch, comprises the steps:

[0043] (1) Acrylate rubber was added to the internal mixer according to the above weight parts, and mixed for 6 minutes under the conditions of processing temperature of 50°C and rotor speed of 60r / min;

[0044] (2) Add white carbon black and paraffin-based operating oil to the internal mixer in step (1) according to the above parts by weight, and continue to Mixing for 6 minutes;

[0045](3) Diisobutylzinc thiophosphate and 2,5-diazabicyclo[2.2.1]heptane were added to the internal...

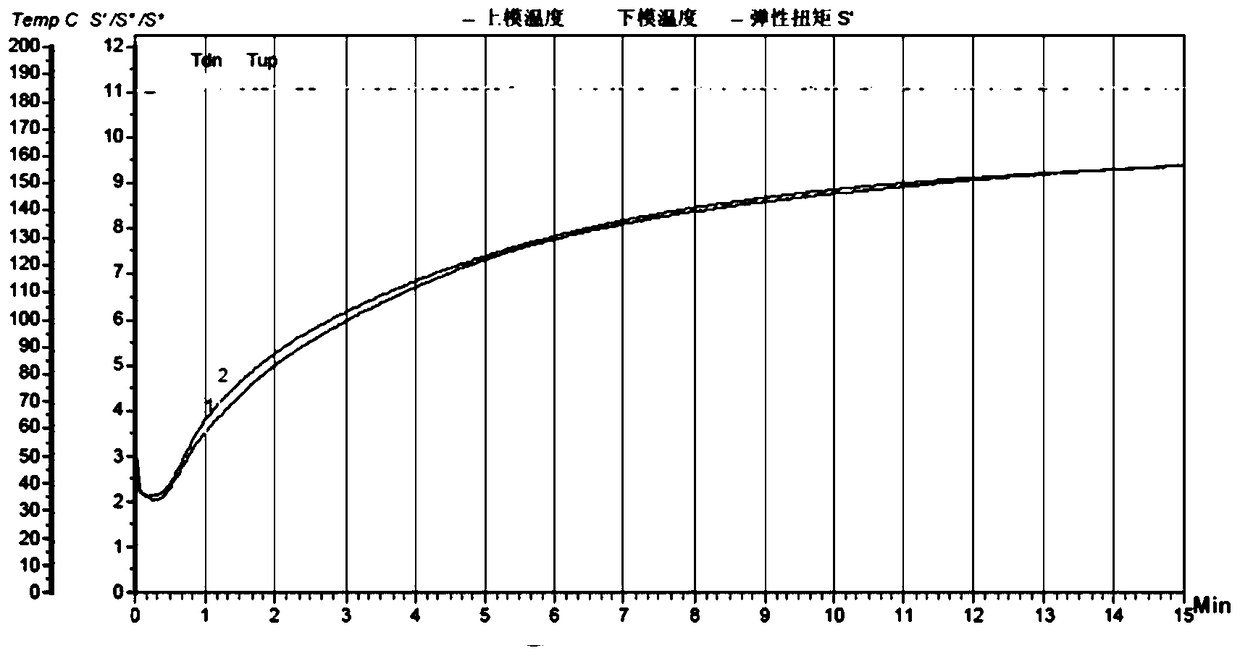

Embodiment 2

[0058] Acrylic rubber accelerator pre-dispersed masterbatch ACT-70-2, based on 100 parts by total weight, its components and parts by weight are as follows:

[0059] 24 parts of ethylene methyl acrylate copolymer, 23 parts of isobutyl octyl bismuth thiophosphate, 23 parts of 3,8-diazabicyclo[3.2.1]octane, 20 parts of calcium carbonate, 9.6 parts of aromatic hydrocarbon operating oil , 0.4 part of starch.

[0060] The preparation method of above-mentioned acrylate rubber accelerator predispersed masterbatch, comprises the steps:

[0061] (1) Add the ethylene acrylate copolymer into the internal mixer according to the above weight parts, and knead for 5 minutes under the condition that the processing temperature is 55°C and the rotor speed is 50r / min;

[0062] (2) Add calcium carbonate and aromatic hydrocarbon operating oil to the internal mixer in step (1) according to the above parts by weight, and continue mixing under the condition that the processing temperature is 60°C an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com