Toughened polyamide resin composite material and preparation method therefor

A technology of resin composite material and polyamide resin, which is applied in the field of composite material and its preparation, can solve the problems of poor toughness and limit the application of polyamide resin, and achieve the effect of good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

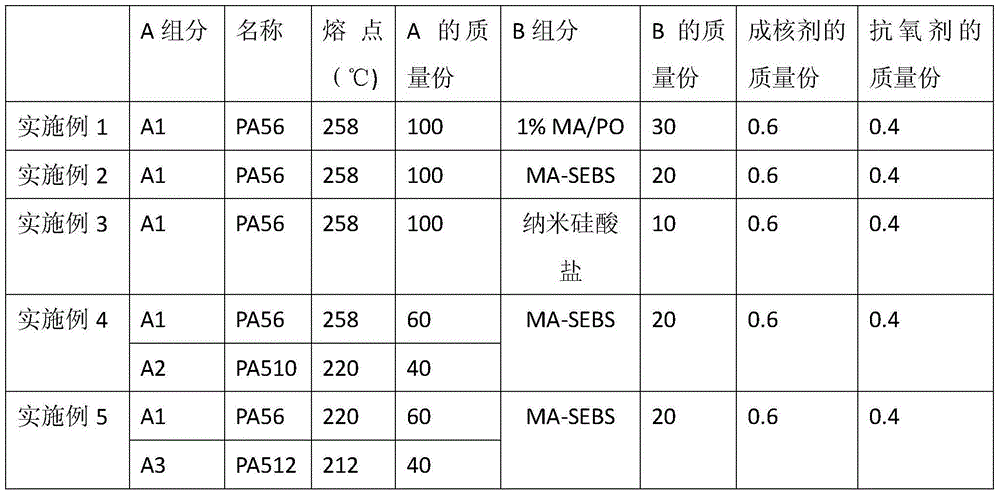

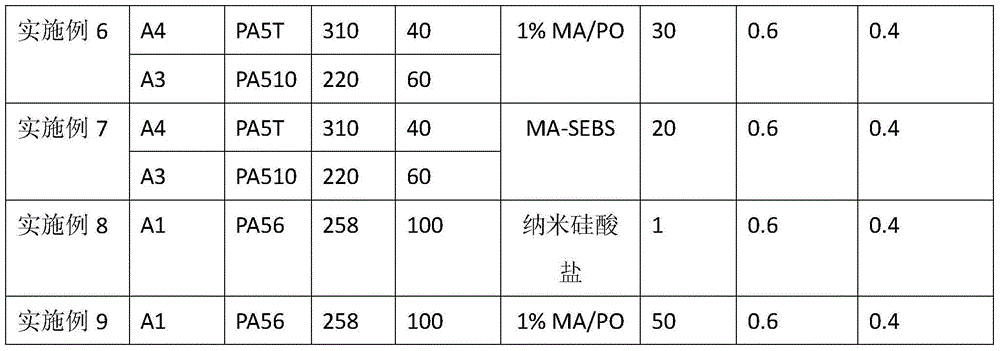

Examples

preparation example Construction

[0034] There is no limitation on the preparation method of the polyamide resin, and any known method can be used, such as salting pentamethylenediamine and aliphatic dibasic acid, followed by polycondensation at high temperature to obtain polyamide resin (nylon resin).

[0035] When preparing the polyamide resin, in order to adjust the molecular weight of the polyamide resin or improve its hot water resistance, an end-capping agent can be further added to the production raw materials of the polyamide resin. The blocking agent is any one or a combination of monocarboxylic acids, monoamines, acid anhydrides, monoisocyanates, monoacyl halides, monoesters and monohydric alcohols. Among them, the acid anhydride includes but not limited to phthalic anhydride. From the standpoint of production stability, monocarboxylic acids or monoamines are preferred as the end-capping agent.

[0036] The monocarboxylic acid that can be used as an end-blocking agent is not particularly limited as ...

manufacture example 1

[0094] The autoclave with an internal volume of 50L replaces the air inside by vacuuming and filling with nitrogen, and protects it with nitrogen;

[0095] A total of 1246 g of pentamethylenediamine and adipic acid in equimolar amounts, and 0.5% of adipic acid relative to the total moles of pentamethylenediamine and adipic acid were dissolved in 30000 g of distilled water to prepare a uniform aqueous solution;

[0096] Put the obtained aqueous solution into an autoclave with an internal volume of 50L, and replace it with nitrogen. Slowly extract the water vapor from the autoclave while stirring at a temperature of 110-150°C, and concentrate the mass concentration of the solution in the autoclave to the initial value. 70% of the mass concentration;

[0097] Raise the internal temperature of the autoclave to 220°C and increase the pressure to 1.8MPa, slowly extract water vapor, keep the pressure at 1.8MPa and react for 1 hour until the internal temperature reaches 260°C;

[009...

manufacture example 2

[0101] The adipic acid in Production Example 1 above was replaced with sebacic acid to obtain polyamide resin PA510 (A2).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com