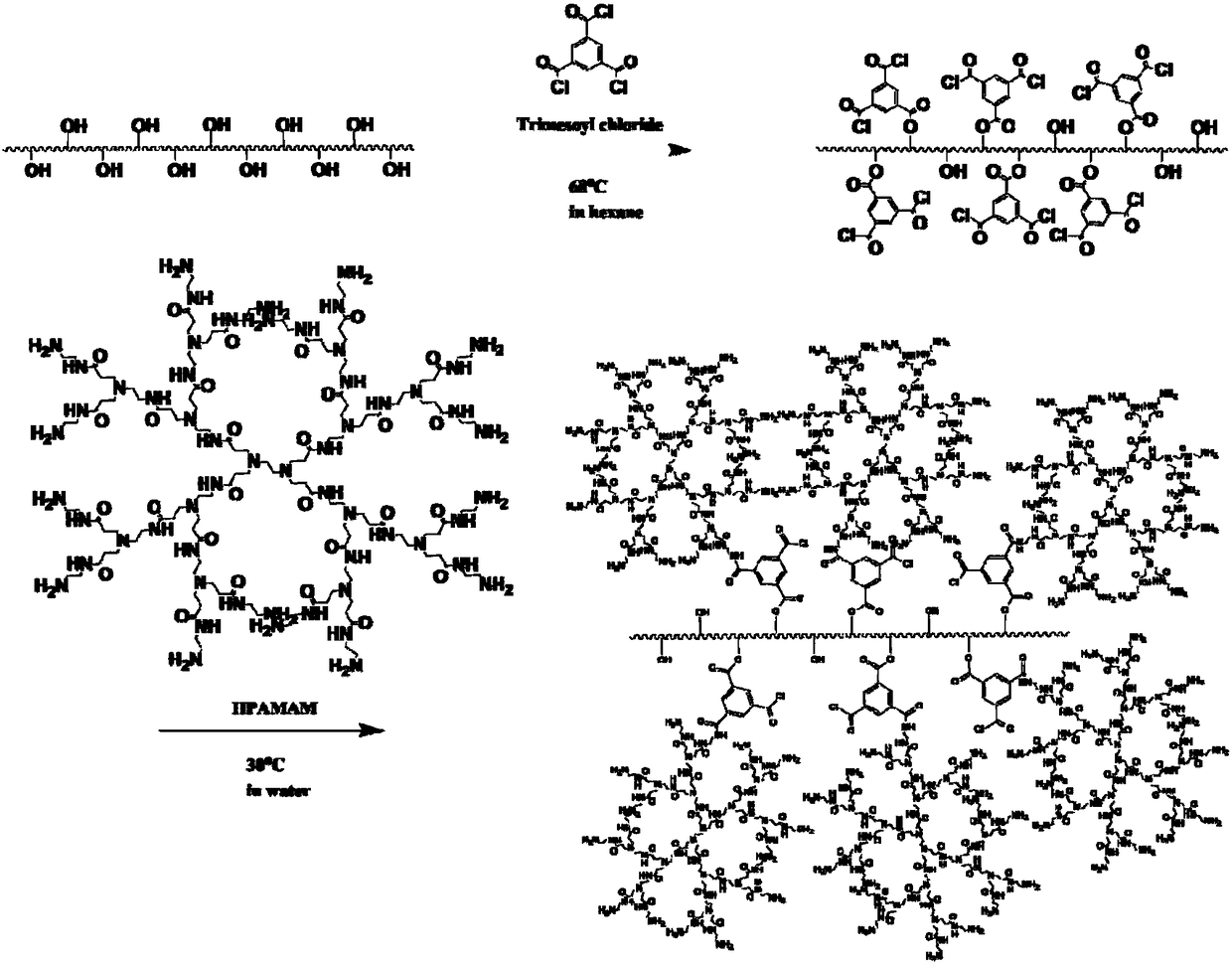

Preparation method of hyperbranched amine polymer modified cotton fiber adsorption material

A technology of adsorption materials and polymers, applied in the fields of alkali metal compounds, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of low cross-linking strength and cross-linking efficiency, inability to reuse, easy to bring in impurities, etc. , to achieve broad application prospects and development space, reduce the cost of preparation process, and the effect of less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The alkalized cotton fiber sample with dry constant weight is completely submerged in 200 g mass concentration of 1% trimesoyl chloride solution, and sealed. Then place it in an ultrasonic cleaning machine and sonicate for 10 min at 40°C. After ultrasonication, take it out and place it in a constant temperature water bath at 40°C for 80 minutes, then wash it with n-hexane for 6 times, spread the cotton fiber sample on the filter paper and place it in an ultrafiltration cup, and put 150g of hyperbranched polyamide with a mass concentration of 5% The amine aqueous solution is poured from above, and after sealing, 0.02MPa nitrogen gas is passed, and the experiment is repeated 5 times to make the hyperbranched polyamidoamine fully pass through the cotton fiber sample. After the end, take it out and wash it with distilled water until the cleaning solution is neutral. Spread the modified cotton fiber sample on a petri dish and place it in a vacuum drying oven at 80°C to dry ...

Embodiment 2

[0045] The alkalized cotton fiber sample with dry constant weight is completely submerged in 150 g of a mass concentration of 3% trimesoyl chloride solution, and sealed. Then place it in an ultrasonic cleaning machine and sonicate for 8 min at 30°C. After ultrasonication, take it out and put it in a constant temperature water bath at 30°C for 100 minutes, then wash it with n-hexane for 5 times, spread the cotton fiber sample on the filter paper and put it in an ultrafiltration cup, and put 100g of hyperbranched polyamide with a mass concentration of 10% The amine aqueous solution is poured from above, and after airtight, 0.03MPa nitrogen gas is passed. The experiment is repeated 6 times, so that the hyperbranched polyamidoamine can fully pass through the cotton fiber sample. After the end, take it out and wash it with distilled water until the cleaning solution is neutral. Spread the modified cotton fiber sample on a petri dish and place it in a vacuum drying oven to dry and ...

Embodiment 3

[0049] The alkalized cotton fiber sample with dry constant weight is completely submerged in 150 g of a mass concentration of 1.5% trimesoyl chloride solution, and sealed. Then place it in an ultrasonic cleaning machine and sonicate for 15 min at 50°C. After ultrasonication, take it out and put it in a constant temperature water bath at 50°C for 60 minutes, then wash it with n-hexane for 4 times, spread the cotton fiber sample on the filter paper and place it in an ultrafiltration cup, and put 200g of hyperbranched polyamide with a mass concentration of 8% The amine aqueous solution is poured from above, and after airtight, 0.01MPa of nitrogen gas is passed to make the hyperbranched polyamidoamine fully pass through the cotton fiber sample, and the experiment is repeated 5 times. After the end, take it out and wash it with distilled water until the cleaning solution is neutral. Spread the modified cotton fiber sample on a petri dish and place it in a vacuum drying oven at 90°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com