Fireproof adhesive for fireproof glass, preparation method thereof and composite fireproof glass

A fireproof glass and fireproof glue technology, applied in the direction of adhesives, adhesive types, inorganic adhesives, etc., can solve the problems of poor apparent quality and a large number of micro-bubbles in the glass interlayer, and achieve long fire protection time and transmittance. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

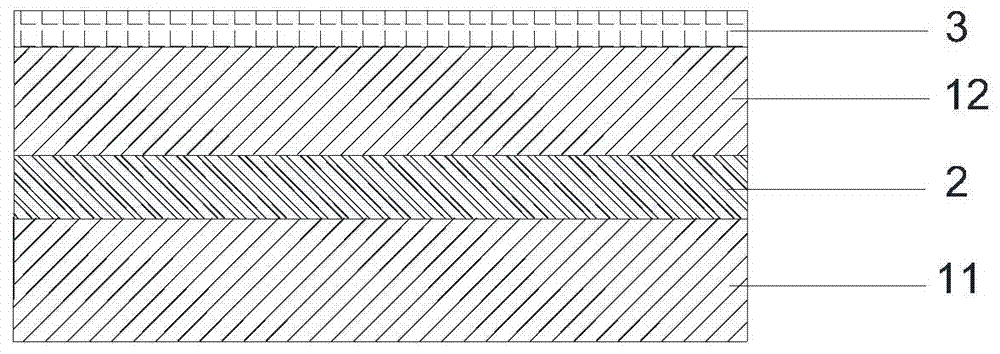

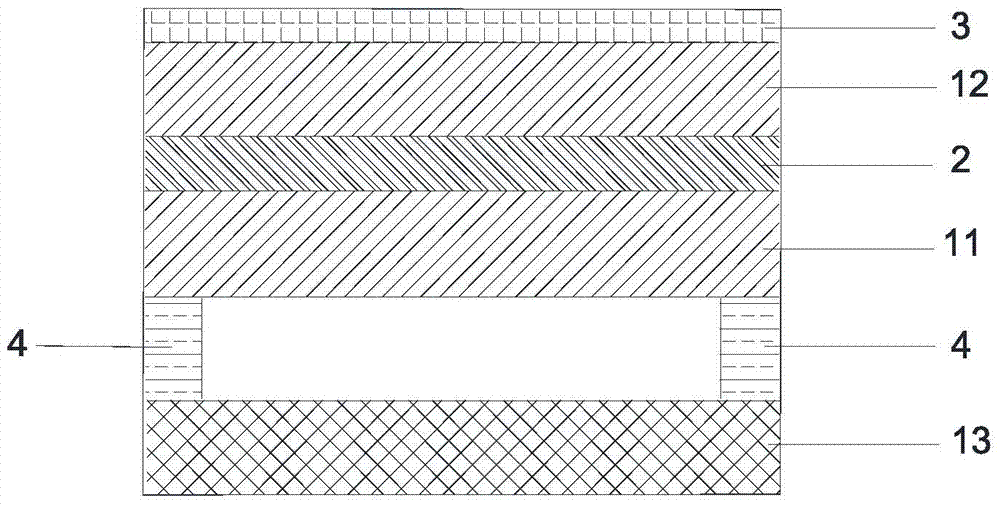

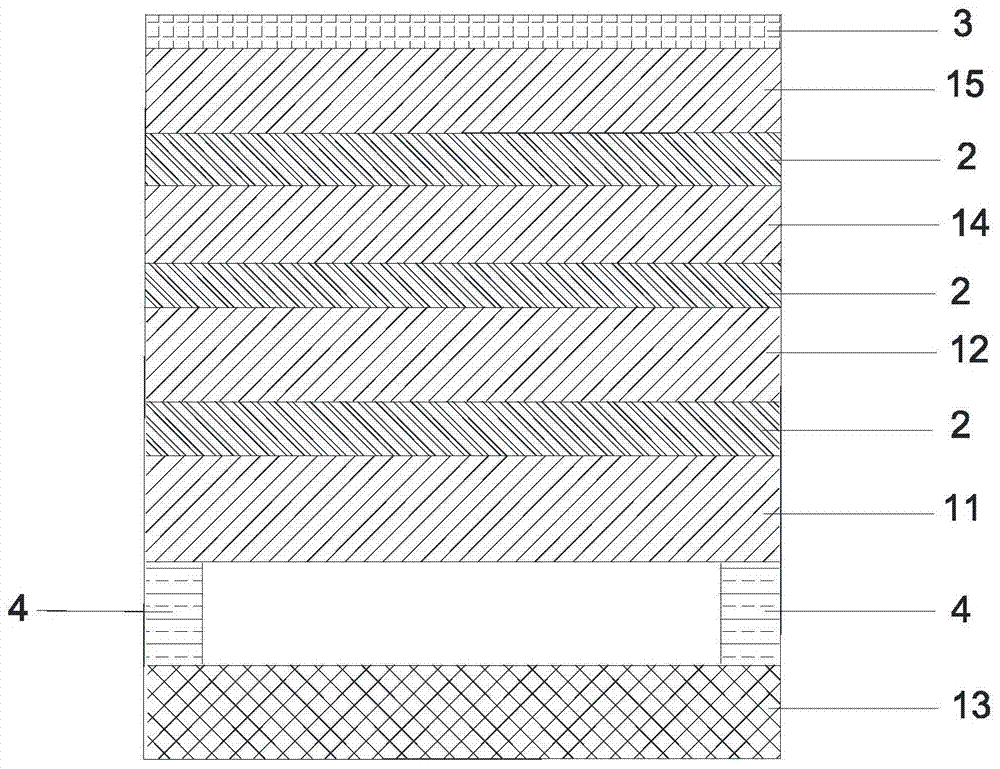

Examples

Embodiment 1

[0028] This embodiment prepares the fireproof glue of fireproof glass according to the following steps:

[0029] (1) Weigh the raw materials of fireproof glue for fireproof glass according to the following weights:

[0030] 75Kg of hydrophilic nano core-shell structure organic-inorganic hybrid particles with a particle size of 40nm and a PDI of 0.008, 75Kg deionized water, 0.5Kg glycerin, 0.5Kg maltose, 0.5Kg sodium hydrogen phosphate, 0.5Kg borax, 0.05Kg oxidation Aluminum, 0.3Kg potassium polyphosphate, 0.1Kg defoamer Tego 902W, 0.3Kg leveling agent RH-212, 0.2Kg sodium fluorosilicate, 45Kg 50% potassium hydroxide aqueous solution. Among them, the core material of the organic-inorganic hybrid particles with a hydrophilic nano-core-shell structure is gas-phase nano-silica particles with a particle size of 100nm and a PDI of 0.002, and the shell material is poly(methacrylic acid) with a shell thickness of 10nm. - acrylic acid-acrylamide) copolymer;

[0031] (2) prepare the f...

Embodiment 2

[0048] This embodiment prepares the fireproof glue of fireproof glass according to the following steps:

[0049] (1) Weigh the raw materials of fireproof glue for fireproof glass according to the following weights:

[0050] 125Kg of hydrophilic nano core-shell structure organic-inorganic hybrid particles with a particle size of 80nm and a PDI of 0.008, 125Kg deionized water, 5Kg glycerin, 3Kg glucose, 3Kg sodium dihydrogen phosphate, 3Kg borax, 0.5Kg starch, 0.6Kg Sodium polyphosphate, 0.2Kg defoamer BYK-024, 0.6Kg leveling agent RH-212, 1Kg aluminum fluoride, 37Kg 50% potassium hydroxide aqueous solution. Among them, the core material of the organic-inorganic hybrid particles with a hydrophilic nano-core-shell structure is gas-phase nano-silica particles with a particle size of 50nm and a PDI of 0.001, and the shell material is poly(methacrylic acid) with a shell thickness of 15nm. - acrylic acid-acrylamide) copolymer;

[0051] (2) The above raw materials were prepared acco...

Embodiment 3

[0066] This embodiment prepares the fireproof glue of fireproof glass according to the following steps:

[0067] (1) Weigh the raw materials of fireproof glue for fireproof glass according to the following weights:

[0068] 100Kg of hydrophilic nano core-shell structure organic-inorganic hybrid particles with a particle size of 80nm and a PDI of 0.008, 100Kg deionized water, 5Kg glycerin, 3Kg fructose, 3Kg potassium hydrogen phosphate, 1.5Kg borax, 1.5Kg boric acid, 0.5Kg Zinc oxide, 0.6Kg sodium polyphosphate, 0.2Kg defoamer BYK-024, 0.6Kg leveling agent RH-212, 1Kg potassium fluorosilicate, 30Kg 50% potassium hydroxide aqueous solution. Among them, the core material of the organic-inorganic hybrid particles with a hydrophilic nano-core-shell structure is gas-phase nano-silica particles with a particle size of 50nm and a PDI of 0.001, and the shell material is poly(methacrylic acid) with a shell thickness of 15nm. - acrylic acid-acrylamide) copolymer;

[0069] (2) The above...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com