Environmental-protection hot melt adhesive for interior and exterior decoration of automobile and preparation method of hot melt adhesive

An automotive interior and exterior decoration, hot melt adhesive technology, applied in the direction of adhesives, adhesive types, polymer adhesive additives, etc. Layer Handy Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

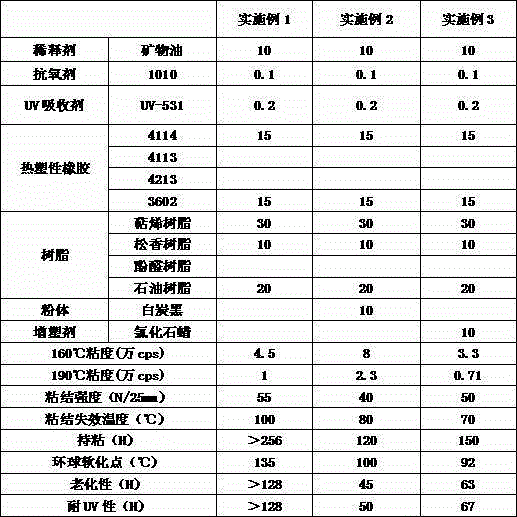

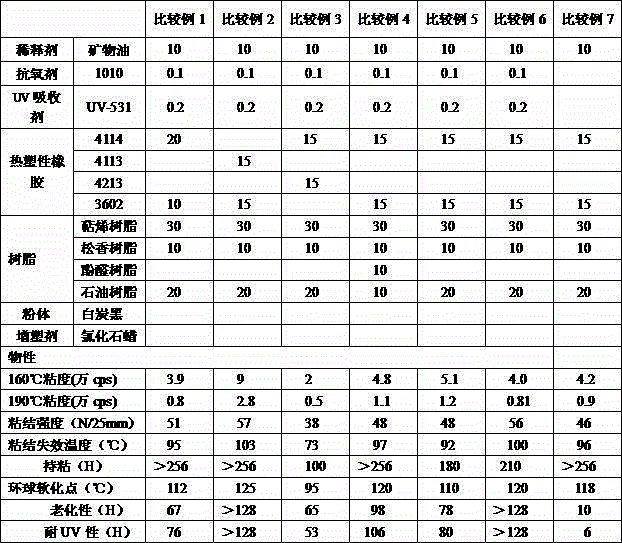

Embodiment 1

[0027] Heat the reactor to 100°C, and add 10 parts of diluent mineral oil. Raise the temperature, and when the temperature reaches 150°C, add 10100.1 parts of antioxidant and 10.2 parts of UV absorber UV-5310.2 parts, stir evenly, continue to add 10 parts of rosin resin, 30 parts of terpene resin, and 20 parts of petroleum resin, and continue stirring. Raise the temperature again to 190°C, add 15 parts each of thermoplastic rubber 4114 and 3206, stir evenly, continue stirring at 180°C for 30 minutes, cool down to 160°C and discharge.

Embodiment 2

[0029] Heat the reactor to 100°C, and add 10 parts of diluent mineral oil. Raise the temperature, and when the temperature reaches 150°C, add 10100.1 parts of antioxidant and 10.2 parts of UV absorber UV-5310. Mix 10 parts of carbon black H20 evenly. Raise the temperature again to 190°C, add 15 parts each of thermoplastic rubber 4114 and 3206, stir evenly, continue stirring at 180°C for 30 minutes, cool down to 160°C and discharge.

Embodiment 3

[0031] Heat the reactor to 100°C, and add 10 parts of diluent mineral oil. Raise the temperature, and when the temperature reaches 150°C, add 10100.1 parts of antioxidant and 10.2 parts of UV absorber UV-5310.2 parts, stir evenly, continue to add 10 parts of rosin resin, 30 parts of terpene resin, 20 parts of petroleum resin, and 10 parts of chlorinated paraffin. Stir continuously. Raise the temperature again to 190°C, add 15 parts each of thermoplastic rubber 4114 and 3206, stir evenly, continue stirring at 180°C for 30 minutes, cool down to 160°C and discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com