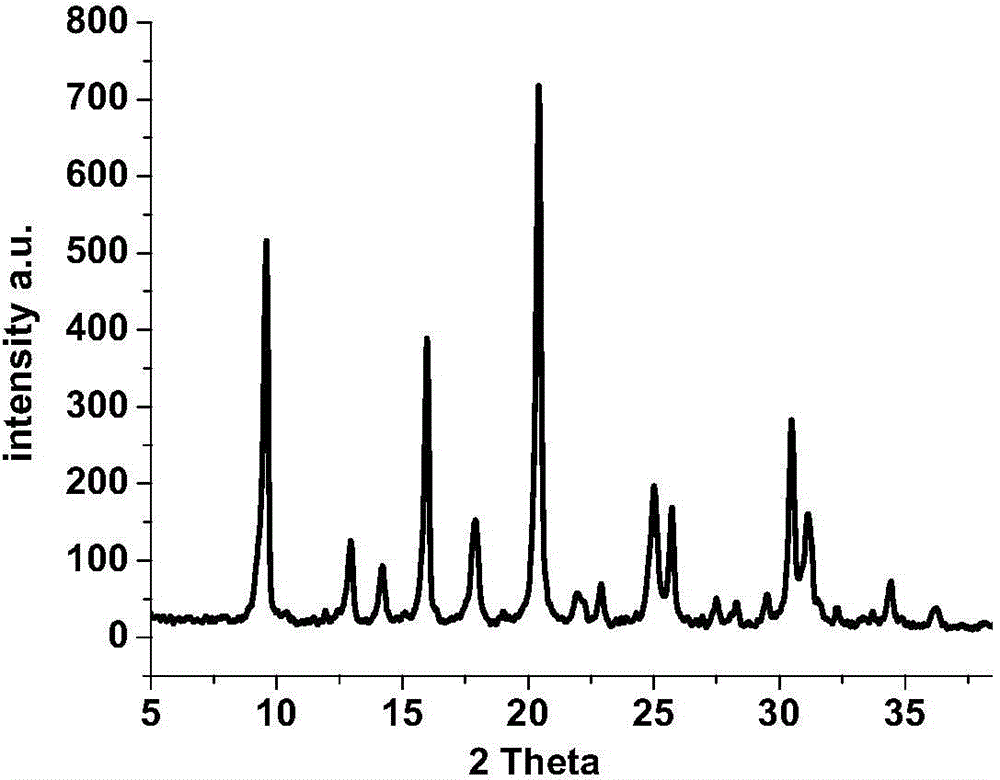

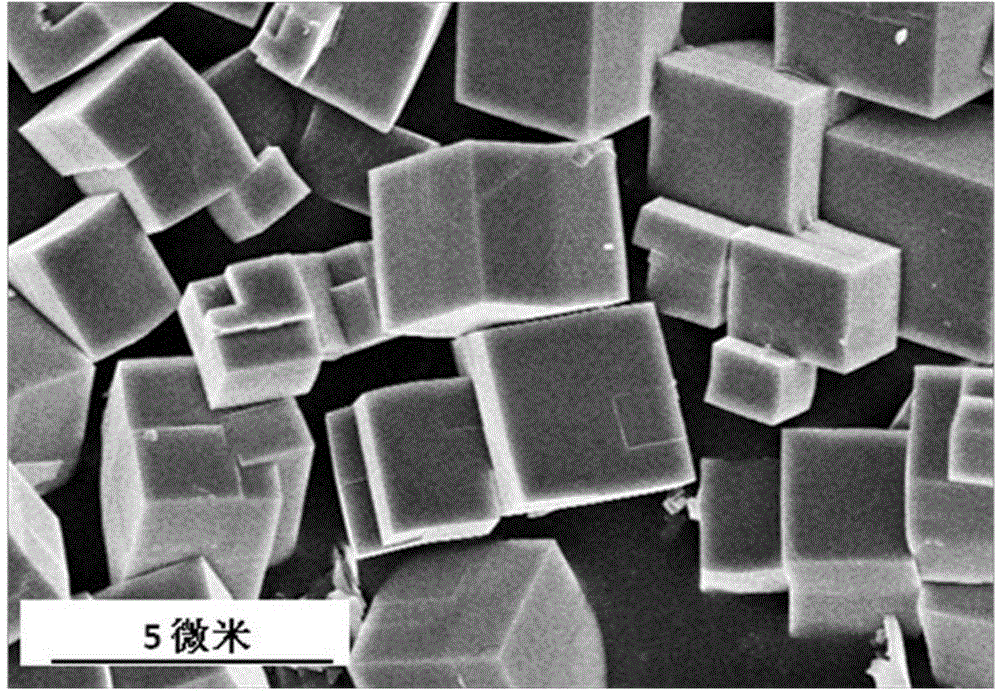

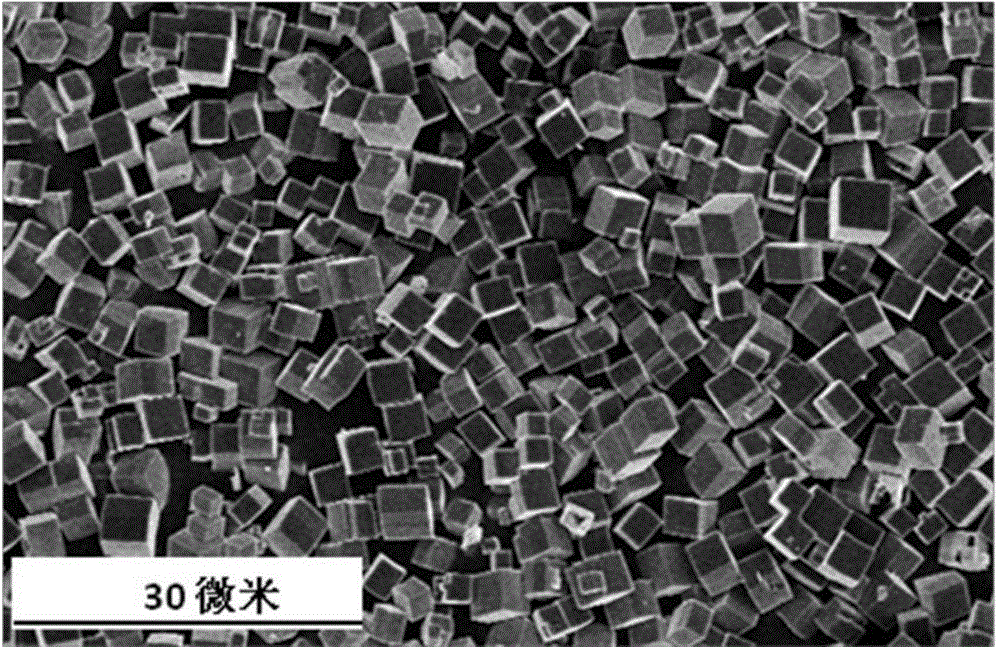

CHA-type silicon-aluminum-phosphorous molecular sieves, and preparation methods and applications thereof

A silicon-aluminum-phosphorus molecular sieve and phosphoric acid technology, applied in separation methods, molecular sieve catalysts, chemical instruments and methods, etc., to achieve the effects of controllable grain size, cost saving, and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] As mentioned above, the present invention discloses a preparation method of the above-mentioned CHA type silicon aluminum phosphorus molecular sieve, which comprises the following steps:

[0059] 1) Compounding sol: After adding silicon source, aluminum source and water to the mixed template agent, add phosphoric acid and stir evenly between 25-45°C;

[0060] 2) Get the sol of step 1), add 0.1-5wt% weight (relative to SiO in the silicon source 2 weight) seed crystals were added into the autoclave, stirred, and crystallized at 165-200° C. for 10-48 hours, wherein the stirring speed was 80-240 rpm.

[0061] In the present invention, the silicon source is selected from inorganic silicon. Preferably, it is silica sol containing silica or solid silica gel for column chromatography.

[0062] In the present invention, the aluminum source is selected from one or more of aluminum hydroxide, pseudoboehmite, aluminum oxide and aluminum powder.

[0063] In the present invention,...

Embodiment 1

[0073] The CHA type silicon aluminum phosphorus molecular sieve is prepared by the following steps:

[0074] 1) Colloidal sol: add silica sol (76.20g, 30%, 0.38 mol), after stirring for half an hour, add water (990 grams, 54.99 moles), and after stirring for half an hour, pseudo-boehmite (109.8g, 76.5%, 0.83mol), add phosphoric acid (219.60g, 85%, 1.91mol), Stir at 35°C for half an hour to obtain a homogeneous translucent colloid.

[0075] 2) Transfer the colloid in step 1) to a 2L autoclave, add 1.00g of seed crystals, crystallize at 180°C for 20 hours under stirring at 120rpm, and filter to obtain the crude product of the CHA-type silicon-aluminum-phosphorus molecular sieve (denoted as molecular sieve X).

[0076] Post-processing is performed as follows:

[0077] i) washing the above-mentioned molecular sieve X with water,

[0078] ii) calcining the product of step i) at 600° C. to obtain the final acidic CHA-type silicon-aluminum-phosphorus molecular sieve (referred to ...

Embodiment 2

[0082] The CHA type silicon aluminum phosphorus molecular sieve is prepared by the following steps:

[0083] 1) Colloidal sol: add triethylamine (278.94g, 99%, 2.67 moles) and adamantane ammonium (adamantane ammonium: R 1 -N + (R 2 ) 3 ) m A m- , where R 1 is adamantane, R 2 The same is methyl, A is hydroxide, m is equal to 186.43g, 23.25%, 0.096 moles), add silica sol (61.23g, 30%, 0.31 moles) to the two-component template agent, stir for half an hour, add water (1080 grams, 60.00 moles), add pseudo-boehmite (128.49g, 76.5%, 0.96 moles) and stir for half an hour, add phosphoric acid (241.36g, 85%, 2.10 moles), and stir for half an hour at 35°C to obtain a uniform half Transparent colloid.

[0084] 2) Transfer the colloid in step 1) to a 2L autoclave, add 0.80g of seed crystals, crystallize at 180°C for 15 hours under stirring at 120rpm, and filter to obtain the crude product of the CHA-type silicon-aluminum-phosphorus molecular sieve (denoted as molecular sieve Y). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com