Preparation method for hyaluronic acid, and anti-adhesive composition comprising hyaluronic acid prepared by same preparation method

A technology of hyaluronic acid and manufacturing method, which is applied in the field of manufacturing, can solve the problems of short residence time and achieve the effect of slow decomposition speed and excellent anti-adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

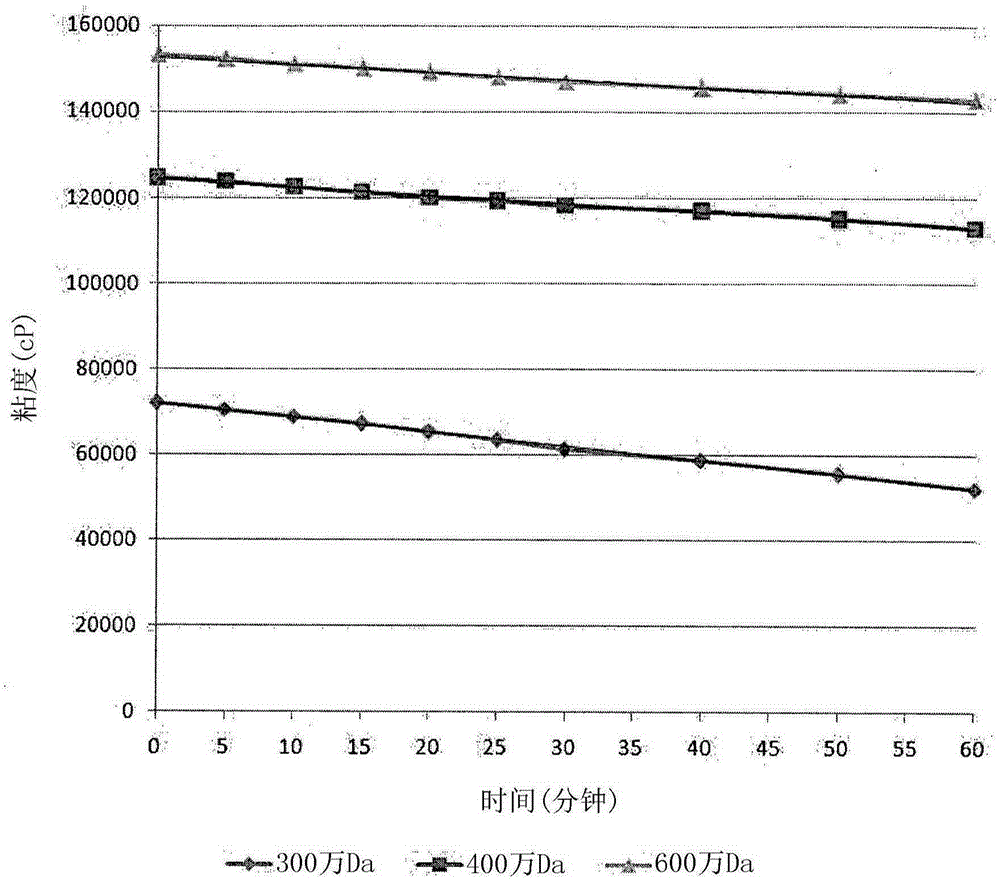

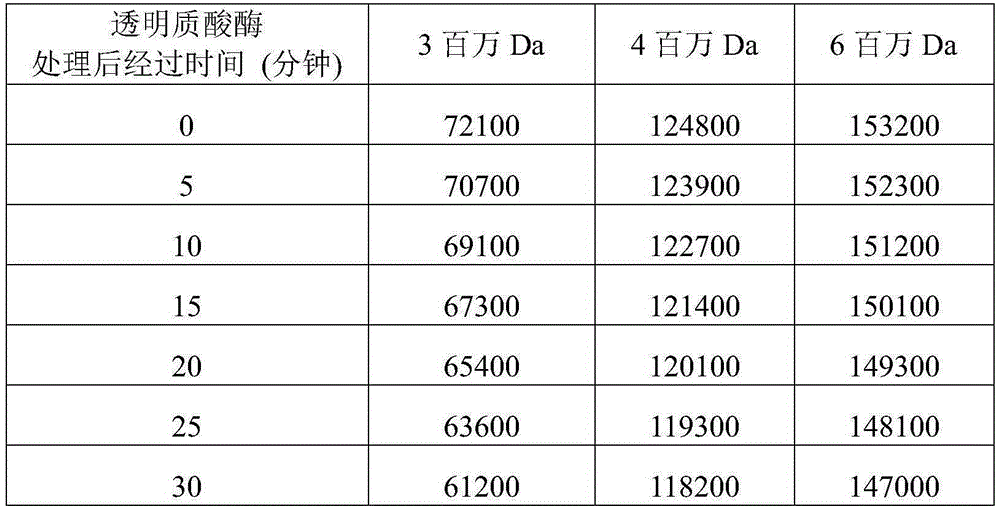

[0065] Anti-adhesion effect experiment brought by molecular weight

[0066] SD rats (female, SPF, Oriental Bio Co., Ltd.) were anesthetized by inhalation, and the anesthesia was continued during the operation. The limbs were fixed on the operating table, the hair on the abdomen was removed with a razor, and the abdomen was cut open with scissors after disinfection. The cecum was taken out, and wounds were made with a roving cloth to the extent that the blood seeped onto the gauze, and the condition that the cecum adhered to the abdominal wall where it was located was created, or the condition that the cecum adhered to the inner peritoneal wall was created by the same method. After the sample was processed, it was sutured, and after 2 weeks of feeding, the abdomen was opened to confirm the state of adhesion. The samples were used by dissolving hyaluronic acid having an average molecular weight of 3 million Da, 4 million Da, and 6 million Da in a sodium phosphate buffer solut...

Embodiment 2

[0069] Basic Culture Conditions for Production of High Molecular Hyaluronic Acid

[0070] Quickly thaw 4ml of the culture solution of Streptococcus dysgalactiae ID9103 strain stored in a freezer at -72°C, spread it on 5.2% brain heart infusion solid medium, cultivate it at 37°C for 24 hours, and cut out 1 cm in length and width. 2 Bacterial colonies grown in the area were inoculated into 3% Todd-Hewitt broth sterilized liquid medium (heart infusion 0.31%, neoptone peptone 2%, glucose 0.2%, disodium hydrogen phosphate 0.04%, sodium carbonate 0.25% ; BD Company, USA) in 40ml.

[0071]40 ml of the culture solution cultured with shaking at 37° C. and 150 rpm was used as the primary seed culture solution. In a 6-hour culturing state in the logarithmic growth stage, inoculate the primary inoculum solution into three 3% Todd-Hewitt broth sterilized liquid medium (40 ml, pH 7.8) in an aseptic manner. The culture conditions were aseptic culture at 37° C. and 150 rpm for 20 hours or...

Embodiment 3

[0076] High Molecular Hyaluronic Acid Productivity and Molecular Weight

[0077] Nitrogen sources are known to play an important role in microbial metabolism and also affect the production of hyaluronic acid. Therefore, it was judged that the production of hyaluronic acid of 4 million Da to 6 million Da can be contributed by changing the amino acids containing peptone as the nitrogen source used basically.

[0078] It was confirmed that the production amount and molecular weight of hyaluronic acid differed depending on the peptones, and among various peptones, casein (enzyme hydrolyzate) as a base medium source showed a production amount exceeding 8 g / L and Molecular weight of 4.32 million Da, and showed the best results, so in the tests of the following examples, casein was also used.

[0079] In the case of the group in which arginine was added instead of glutamine as the basic medium, the production amount and molecular weight of hyaluronic acid showed excellent results of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com