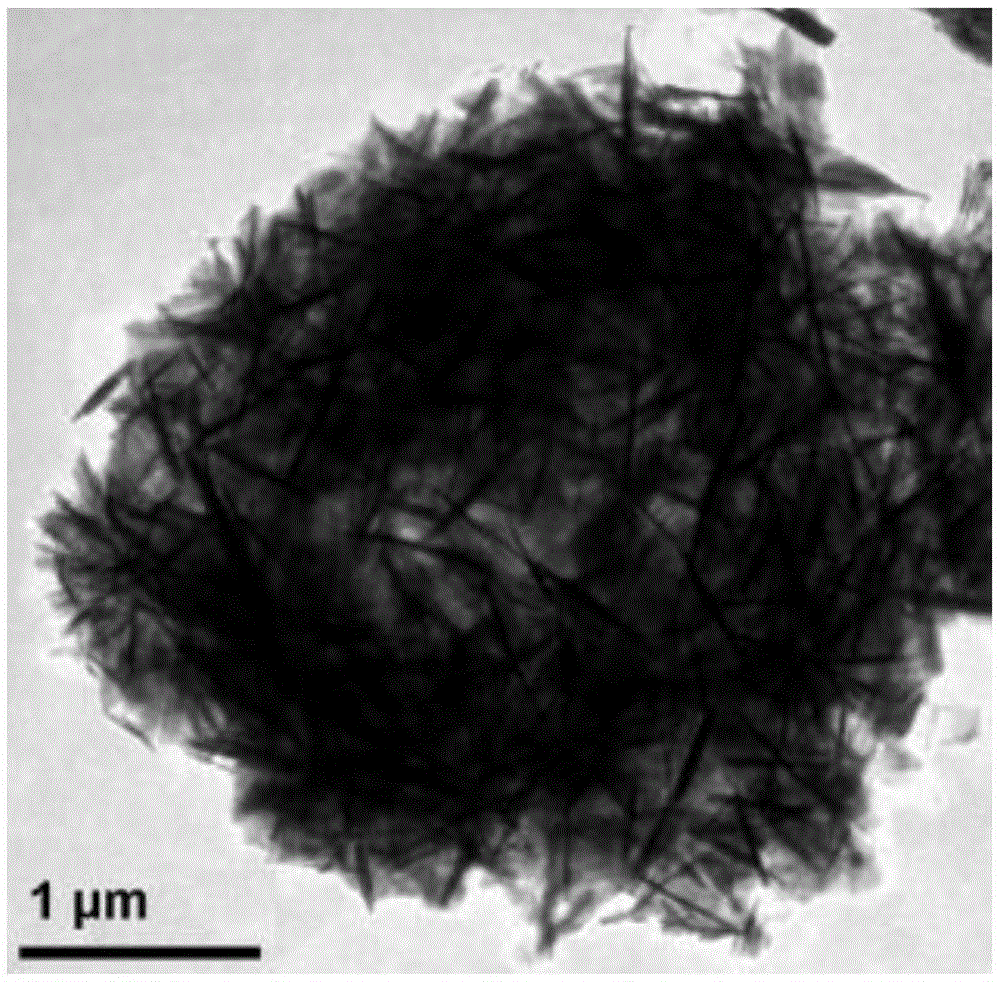

Method for synthesizing Ti-MWW molecular sieve hollow sphere with high external specific surface area

A specific surface area and synthesis method technology, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of cumbersome method process and achieve the effects of improving uniformity, promoting rapid and high-quality nucleation, and excellent catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

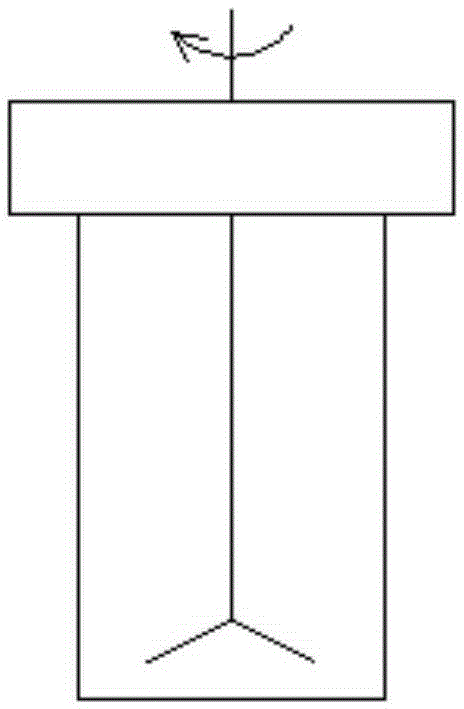

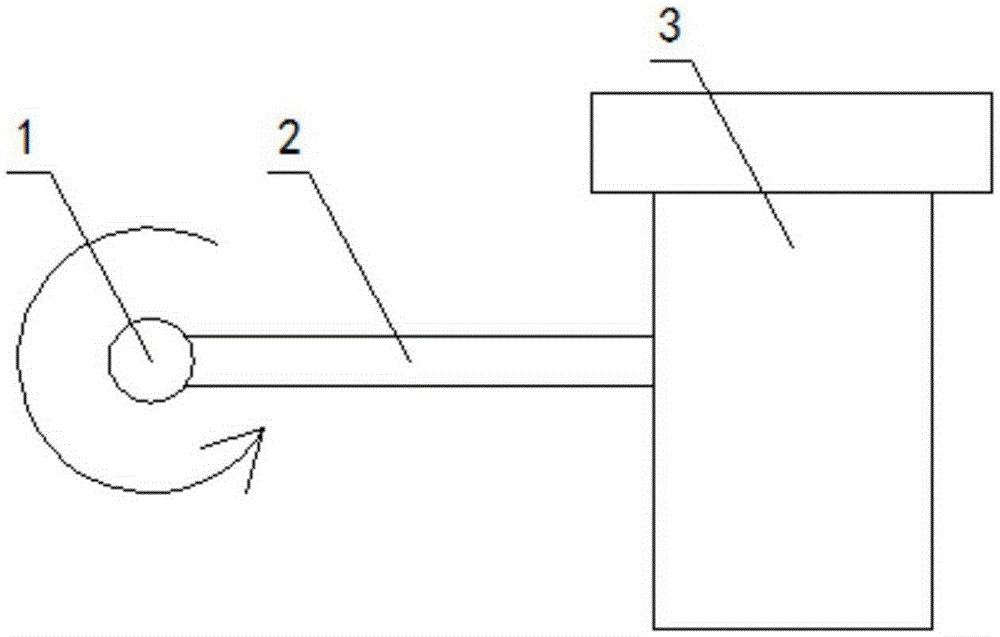

[0034] At room temperature, add a certain amount of organic amine to a certain amount of water, stir for half an hour, then add titanium source, boron source and stir evenly, then add a certain amount of silicon source to obtain a reaction gel, the gel molar composition is 0.04 TiO 2 : 1.0 SiO 2 : 0.67B 2 o 3 : 1.5 organic amine: 25.0H 2 O. Such as figure 2 As shown, the reaction gel is placed in a closed reactor 3, and the closed reactor 3 is fixed on the horizontal rotating shaft 1 of the homogeneous reactor through a connecting rod 2, and the rotation rate is adjusted to 40 revolutions per minute, and it is first aged at 90°C 14 hours. Then adjust the rotation rate to 60 rpm, crystallize at 185°C for 46 hours, filter, wash and dry to obtain the original powder of Ti-MWW molecular sieve, the titanium source is n-butyl titanate, and the silicon source is silicon dioxide, the boron source is boric acid, and the organic amine is piperidine. Mix the obtained molecular s...

Embodiment 2~10

[0036] Implementation process except following difference, all the other are all the same as embodiment 1, see table 1.

[0037] Table 1

[0038]

[0039] In other embodiments, according to the technical solution provided by the present invention, the ratio of raw materials is adjusted within the given range, and the performance of the obtained product is equivalent, which all conform to the technical idea of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com