Zinc cyanide barren solution treatment method

A technology of cyanidation lean liquid and treatment method, which is applied in chemical instruments and methods, metallurgical wastewater treatment, water/sewage multi-stage treatment, etc. problem, to achieve the effect of efficient recovery, easy implementation and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

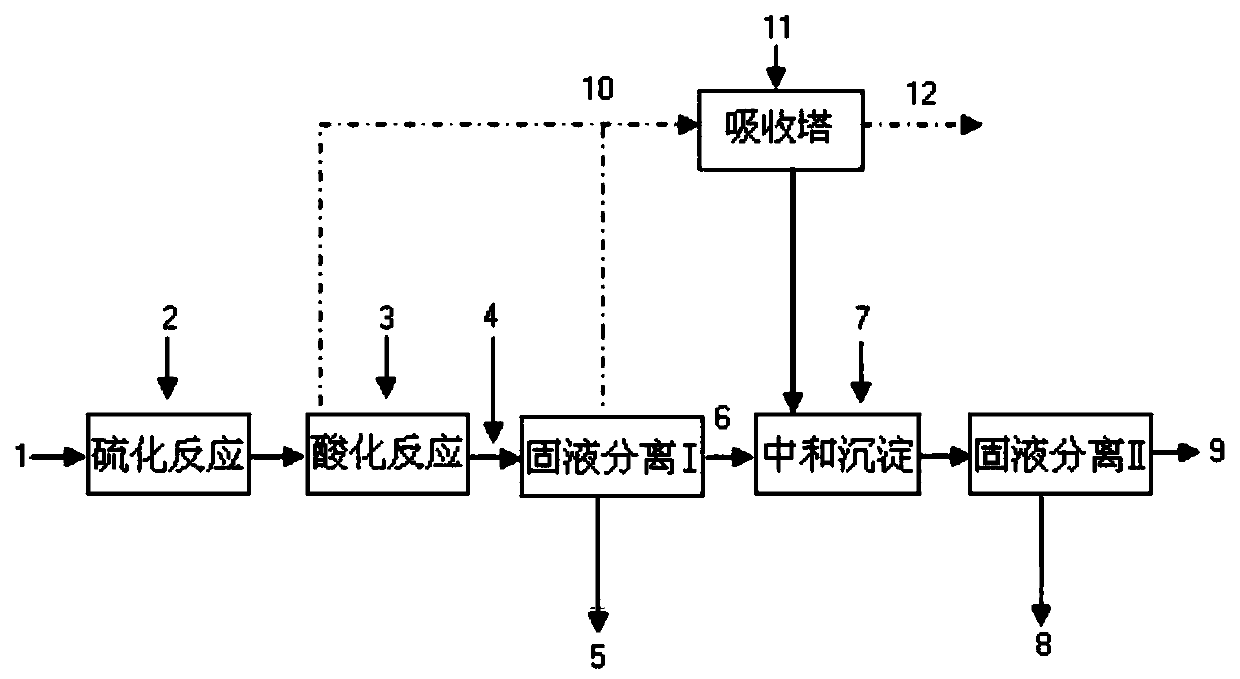

Method used

Image

Examples

Embodiment 1

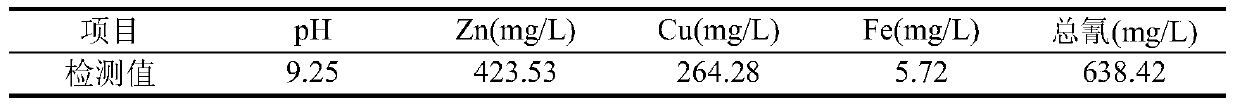

[0034] Embodiment 1: Get a certain gold mine zinc cyanide barren solution, its water quality index is shown in Table 1.

[0035] Table 1 Analysis results of water quality of zinc-containing cyanide barren solution in a gold mine

[0036]

[0037] Get this cyanide barren solution of 50L and adopt process of the present invention to process:

[0038] The first step: sulfuration and acidification process, add 1.4g / L industrial sodium sulfide with a purity of 60% to the cyanide barren solution, stir and mix for 5 minutes, pump to the reactor, adjust its pH to 4.5 with concentrated sulfuric acid, and stir for 10 minutes. Add 1-2 mg / L PAM, let it stand in the sedimentation tank for 30 minutes, separate the solid and liquid I, and separate the supernatant 6 and the sediment I 5 with a dry weight of 1.08 g / L. The zinc grade in the sediment I is 38.04% and the copper grade is 24.15%. Sediment I 5 and cyanidation tailings will be treated separately;

[0039] The second step: neutra...

Embodiment 2

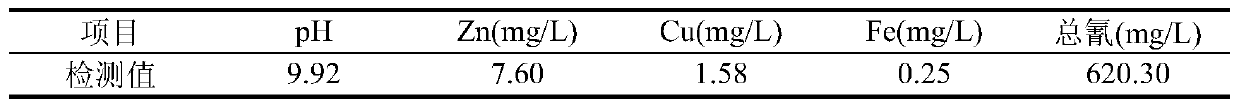

[0049] Carry out the processing of zinc cyanide poor solution repeatedly by the same step of example 1, but difference is that former zinc cyanide poor solution water quality is different (seeing table 5), the first step soluble sulfide 2 sodium sulfide consumption is 5.83g / L, other technical parameters and steps are the same as in Example 1.

[0050] Table 5 Water quality analysis results of zinc-containing cyanide barren solution

[0051]

[0052] After Example 2 was treated by the above method, the analysis results of the effluent water quality are shown in Table 6.

[0053] Table 6 Analysis results of water quality after cyanide removal in cyanidation wastewater of an oxide ore dressing and smelting plant

[0054]

[0055] The dry weight of sediment I 5 produced in the first step is 4.32g / L, the grade of zinc in sediment I is 36.80%, and the grade of copper is 27.38%.

[0056] The metal balance of zinc and copper in the zinc cyanide barren solution process in the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com