Biological function organic-inorganic compound fertilizer containing amino acid, humic acid and nicotine and preparation method of biological function organic-inorganic compound fertilizer

A compound fertilizer and humic acid technology, applied in fertilizer mixture, fertilization device, application, etc., can solve problems such as nutrient supply imbalance, achieve the effects of reducing pest damage, enhancing stress resistance, and rapid fertilizer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

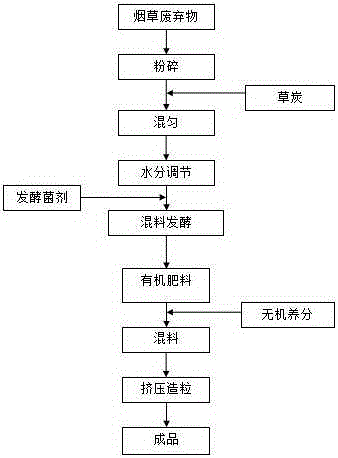

[0017] 1) Pretreatment of raw materials: pulverize the tobacco waste raw materials rich in amino acids, humic acid and nicotine into 20-40 mesh powder, then use rice bran and sawdust to adjust the carbon-nitrogen ratio of the raw materials to 25:1, and then use CaCO 3 Adjust pH value to 6, moisture content is adjusted to (weight percent) 45%;

[0018] 2) Mixing fermentation: add the above-mentioned pretreated materials to fermenting bacteria with a total weight of 0.3% of the material, and then stack them for fermentation after mixing evenly. The fermentation bacteria are organic materials produced by Yunnan Microbial Fermentation Engineering Research Center Co., Ltd. The decomposing agent is turned over during the fermentation process, at least once a day, to promote water evaporation and oxygen supply in the solid fermentation. When the temperature in the heap drops to room temperature, the fermentation ends, and the organic fertilizer containing amino acids, humic acid and n...

Embodiment 2

[0022] 1) Pretreatment of raw materials: pulverize the tobacco waste raw materials rich in amino acids, humic acid and nicotine into 20-40 mesh powder, then use rice bran and sawdust to adjust the carbon-nitrogen ratio of the raw materials to 30:1, and then use CaCO 3 Adjust the pH value to 7, and adjust the moisture content to (weight percent) 50%;

[0023] 2) Mixed fermentation: add the above-mentioned pretreated materials to fermenting bacteria with a total weight of 0.4% of the total material weight. The fermentation bacteria is an organic material decomposing agent produced by Yunnan Microbial Fermentation Engineering Research Center Co., Ltd., which is mixed evenly and then stacked. Fermentation is carried out, and the heap is turned during the fermentation process, and the heap is turned at least once a day to promote the evaporation of water and oxygen supply in the solid fermentation. fertilizer;

[0024] 3) Preparation of inorganic fertilizer: take 12.5 parts by wei...

Embodiment 3

[0027] 1) Pretreatment of raw materials: pulverize the tobacco waste raw materials rich in amino acids, humic acid and nicotine into 20-40 mesh powder, then use rice bran and sawdust to adjust the carbon-nitrogen ratio of the raw materials to 28:1, and then use CaCO 3 Adjust the pH value to 6.5, and adjust the moisture content to (weight percent) 55%;

[0028] 2) Mixed fermentation: add the above-mentioned pretreated materials to fermenting bacteria with a total weight of 0.5% of the total material weight. The fermentation bacteria are organic material decomposing agents produced by Yunnan Microbial Fermentation Engineering Research Center Co., Ltd., and stack them after mixing evenly. Fermentation is carried out, and the heap is turned during the fermentation process, and the heap is turned at least once a day to promote the evaporation of water and oxygen supply in the solid fermentation. fertilizer;

[0029] 3) Preparation of inorganic fertilizer: take 8.5 parts by weight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com