Flash photo frame

A photo frame and body technology, applied in coatings, anti-corrosion coatings, etc., can solve the problems affecting the appearance of metal flash coatings, water resistance, salt spray resistance, hardness, easy coalescence of metal particles, irregular arrangement of metal particles, etc. Achieve excellent water resistance, improve cross-linking degree and strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

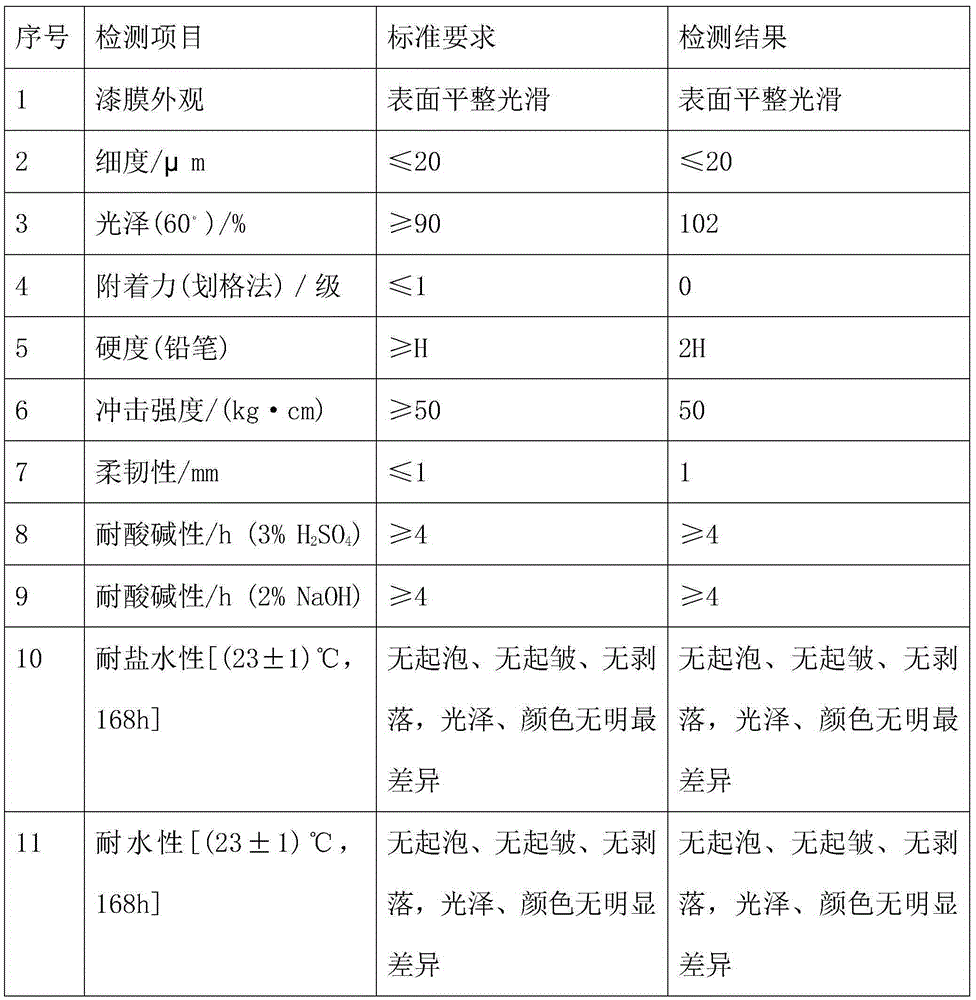

Examples

Embodiment 1

[0019] In this embodiment, a flash photo frame includes a photo frame body and a flash coating on the photo frame body; the flash coating is formed by spraying the flash paint on the surface of the photo frame body; the raw materials of the flash paint include by weight: 55 parts of water-based polyacrylate emulsion, 20 parts of water-based amino resin, 2 parts of coated aluminum powder, 8 parts of nano-titanium dioxide, 1 part of vermiculite powder, 5 parts of perlite powder, 2 parts of wax dispersion, 5 parts of isopropanol, 0.3 parts of ethylene glycol monobutyl ether, 0.6 parts of sodium hexametaphosphate, 1 part of dispersant SN50401, 1 part of sodium tripolyphosphate, 0.5 parts of associative polyurethane thickener, 0.8 parts of AMP-950, 0.5 parts of silane coupling agent, Leveling agent BYK-3310.8 parts, defoamer 0.2 parts, deionized water 65 parts;

[0020] The preparation method of the coated aluminum powder comprises: stirring and mixing 5 parts of polyethylene glyco...

Embodiment 2

[0024] In this embodiment, a flash photo frame includes a photo frame body and a flash coating on the photo frame body; the flash coating is formed by spraying the flash paint on the surface of the photo frame body; the raw materials of the flash paint include by weight: 75 parts of water-based polyacrylate emulsion, 10 parts of water-based amino resin, 10 parts of coated aluminum powder, 3 parts of nano-titanium dioxide, 5 parts of vermiculite powder, 1 part of perlite powder, 6 parts of wax dispersion, 3 parts of isopropanol, 0.5 parts of ethylene glycol monobutyl ether, 0.3 parts of sodium hexametaphosphate, 3 parts of dispersant SN50403, 0.5 parts of sodium tripolyphosphate, 1 part of associative polyurethane thickener, 0.4 parts of AMP-950, 1 part of silane coupling agent, Leveling agent BYK-3310.3 parts, defoamer 0.4 parts, deionized water 35 parts;

[0025] The preparation method of the coated aluminum powder comprises: stirring and mixing 10 parts of polyethylene glyco...

Embodiment 3

[0029] In this embodiment, a flash photo frame includes a photo frame body and a flash coating on the photo frame body; the flash coating is formed by spraying the flash paint on the surface of the photo frame body; the raw materials of the flash paint include by weight: 60 parts of water-based polyacrylate emulsion, 18 parts of water-based amino resin, 4 parts of coated aluminum powder, 7 parts of nano-titanium dioxide, 2 parts of vermiculite powder, 4 parts of perlite powder, 3 parts of wax dispersion, 5 parts of isopropanol, 0.3 parts of ethylene glycol monobutyl ether, 0.5 parts of sodium hexametaphosphate, 1 part of dispersant SN50401, 0.8 parts of sodium tripolyphosphate, 0.7 parts of associative polyurethane thickener, 0.7 parts of AMP-950, 0.6 parts of silane coupling agent, Leveling agent BYK-3310.7 parts, defoamer 0.2 parts, deionized water 55 parts;

[0030] The preparation method of the coated aluminum powder comprises: stirring and mixing 7 parts of polyethylene g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com