A preparation method of ldhs/pva composite membrane and its application in heavy metal wastewater

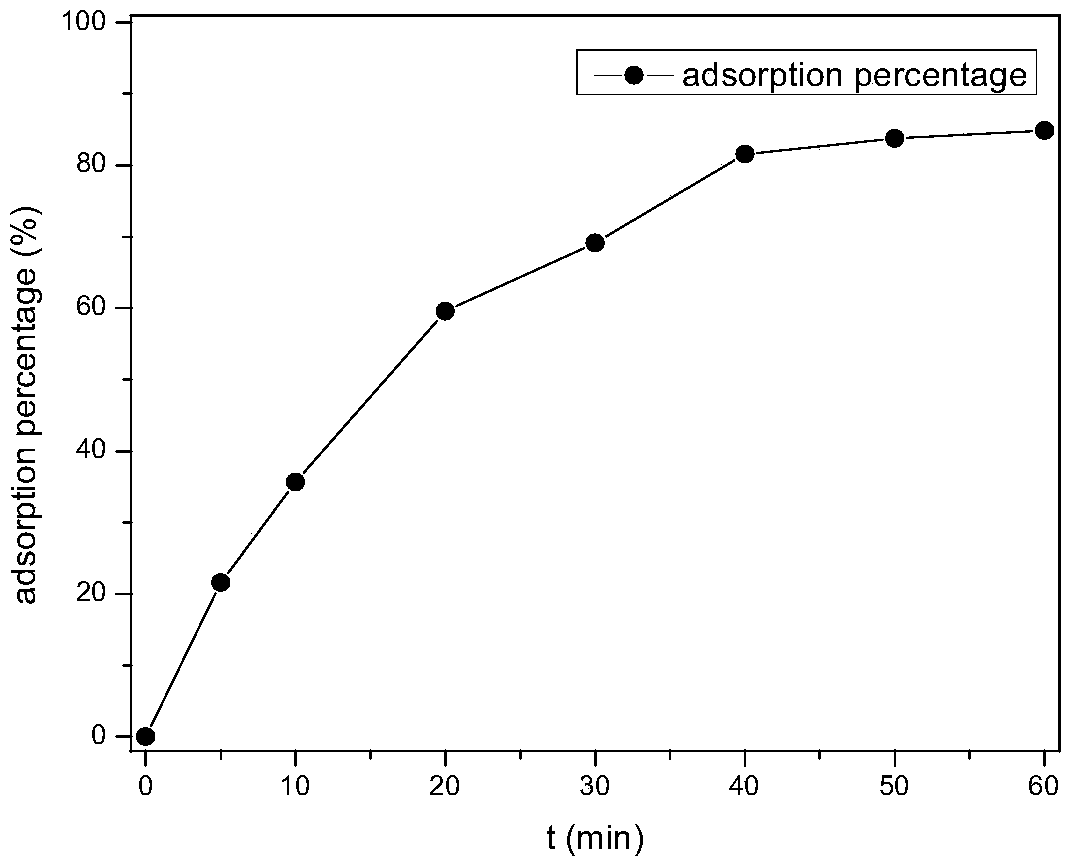

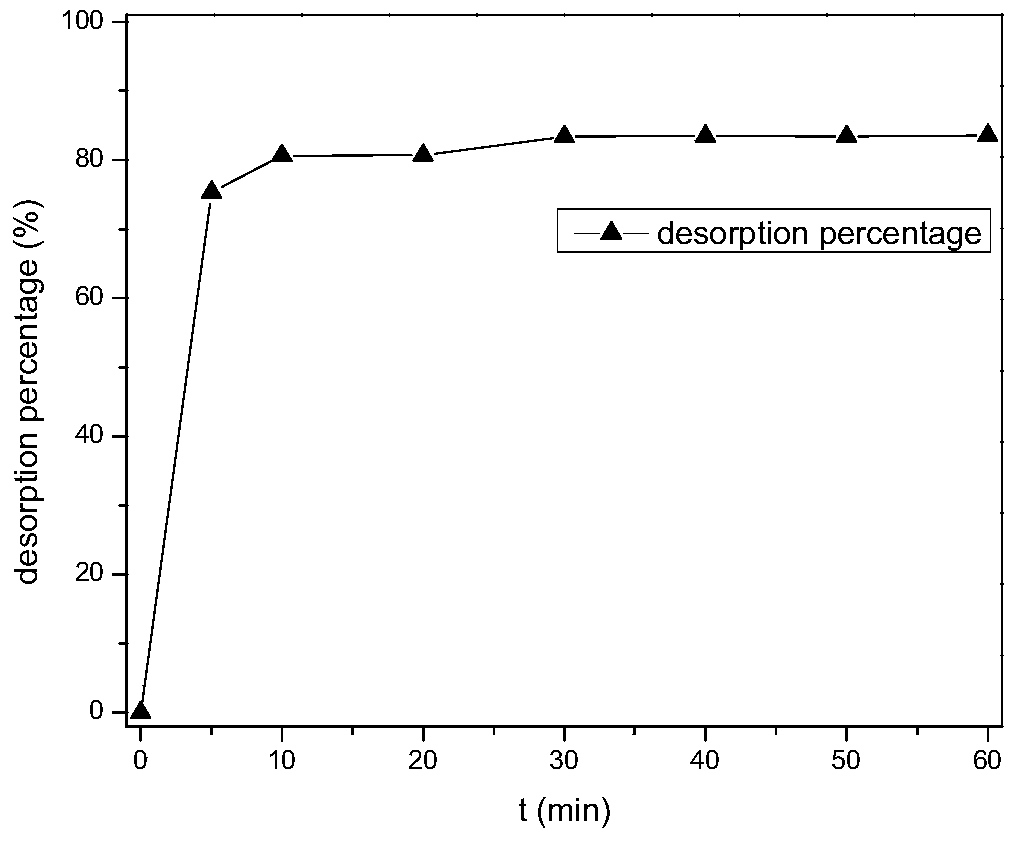

A composite membrane and heavy metal technology, which is applied in the fields of alkali metal compounds, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of adsorption material loss, adsorption separation and recovery difficulties, etc., to achieve recycling, low cost, The effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

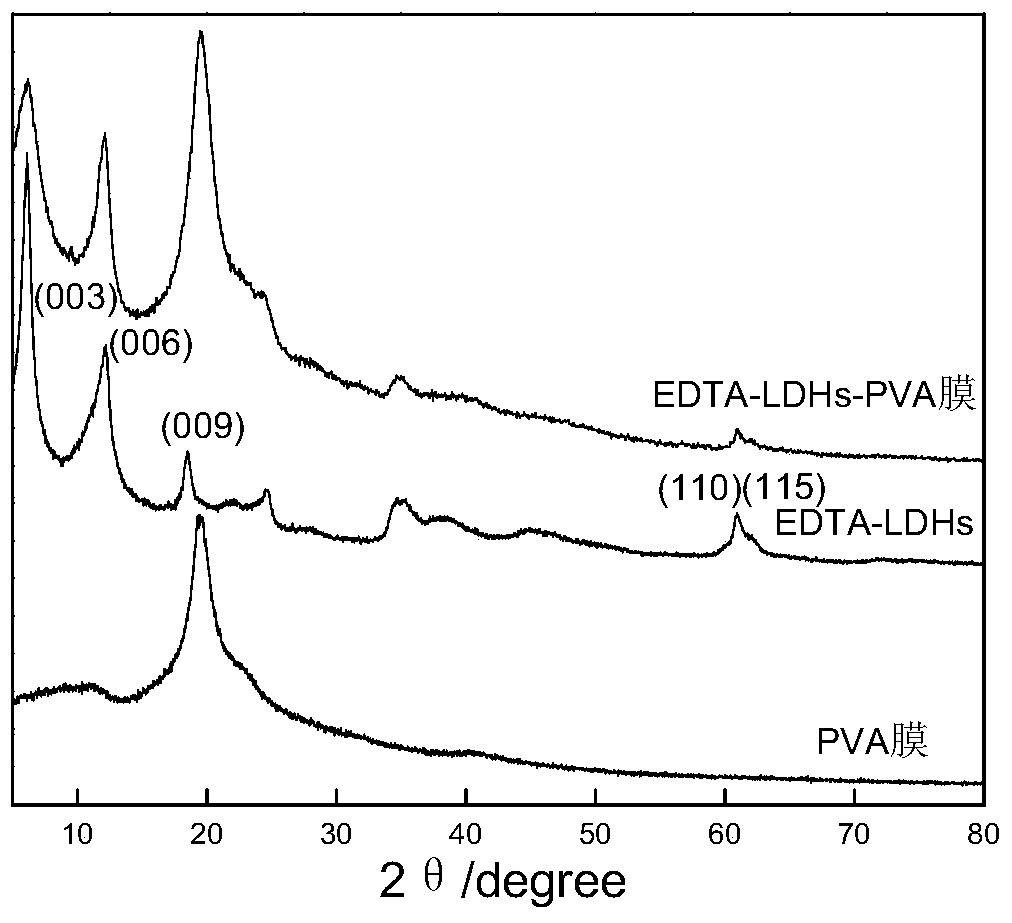

Embodiment 1

[0031] 1. Preparation of LDHs / PVA composite membrane

[0032] (1) Prepare 4.0M Mg (NO 3 ) 2 aqueous solution and 1.0M Al (NO 3 ) 3 0.1L of the aqueous solution, respectively recorded as solution A and B; take 0.10 mol of sodium ethylenediamine tetraacetate fully dispersed in distilled water, recorded as solution C;

[0033] (2) Add solution A and solution B to solution C dropwise under the condition of nitrogen protection and constant stirring of solution C;

[0034] (3) After the dropwise addition, adjust the pH value to 9.0 with a 20% NaOH solution by mass ratio, react for 60 minutes, and obtain the sample; place the sample at 80°C for 12 hours;

[0035] (4) Wash the aged sample with distilled water until the pH of the final filtrate is 7, filter, and vacuum-dry the obtained filter cake at a temperature range of 80°C for 8 hours, crush it, and pass it through a 200-mesh sieve to obtain ethylenediaminetetra Acetate intercalated hydrotalcite;

[0036] (5) Weigh 2g of PVA...

Embodiment 2

[0047] 1. Preparation of LDHs / PVA composite membrane

[0048] (1) Prepare 3.0M Zn (NO 3 ) 2 aqueous solution and 1.0M Fe(NO 3 ) 3 0.1L of the aqueous solution, recorded as solution A and solution B; take 0.20 mol of sodium tartrate fully dispersed in distilled water, recorded as solution C;

[0049] (2) Add solution A and solution B to solution C dropwise under the condition of nitrogen protection and constant stirring of solution C;

[0050] (3) After the dropwise addition, adjust the pH value to 8.0 with a 20% NaOH solution by mass ratio, react for 45 minutes, and obtain the sample; place the sample at 80°C for 14 hours;

[0051] (4) Wash the aged sample with distilled water until the pH of the final filtrate is 7, filter, and vacuum-dry the obtained filter cake at a temperature range of 80°C for 6 hours, crush it, and pass it through a 150-mesh sieve to obtain ethylenediaminetetra Acetic acid intercalated hydrotalcite;

[0052] (5) Weigh 3g of PVA and add it to 30g of...

Embodiment 3

[0059] 1. Preparation of LDHs / PVA composite membrane

[0060] (1) Prepare 2.0M Fe (NO 3 ) 2 aqueous solution and 1.0M Co(NO 3 ) 3 0.1L of aqueous solution, recorded as solutions A and B; take 0.15 mol of sodium citrate fully dispersed in distilled water, recorded as solution C;

[0061] (2) Add solution A and solution B to solution C dropwise under the condition of nitrogen protection and constant stirring of solution C;

[0062] (3) After the dropwise addition, use 20% NaOH solution and 1M nitric acid to adjust the pH value to 9.5, react for 90 minutes, and obtain the sample; place the sample at 80°C for 12 hours;

[0063] (4) Wash the aged sample with distilled water until the pH of the final filtrate = 7, filter, and vacuum-dry the obtained filter cake at a temperature range of 80°C for 10 hours, crush it, and pass it through a 200-mesh sieve to obtain citric acid intercalation Hydrotalcite;

[0064] (5) Add 2.5g of PVA to 27g of distilled water, and stir vigorously t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com