A method for removing cyanide in cyanide-containing wastewater by using ionic liquid supported liquid membrane technology

An ionic liquid, supporting liquid membrane technology, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems that wastewater is difficult to meet discharge standards, cannot destroy metal complexes, and is difficult to synthesize pharmaceuticals. , to achieve the effect of short enrichment period, mild operating conditions and large enrichment multiples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

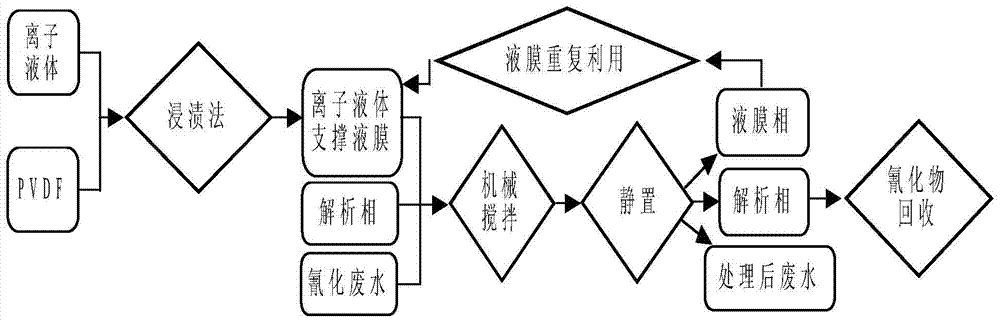

[0025] As shown in Figure 1, the sodium hydroxide solution of 1.0mol / L, 3.0mol / L, and 5.0mol / L is used as the analytical phase, and the liquid phase is 468.36mg / L of cyanide wastewater (from a gold smelting factory in Henan). Plant, the pH has been adjusted with sulfuric acid to be 5), the stirring extraction time is 60min, and the stirring speed is 200rmp. After the ionic liquid supported liquid membrane extraction, the removal rates of cyanide in the wastewater are 82.92%, 95.05%, and 87.06%, respectively.

Embodiment 2

[0027] As shown in Figure 1, with 3.0mol / L sodium hydroxide solution as the analytical phase, cyanide wastewater of 117.09mg / L, 234.18mg / L, and 468.36mg / L (from a gold smelter in Henan, which has been Sulfuric acid was used to adjust the pH to 5) as the material-liquid phase, the stirring extraction time was 60min, and the stirring speed was 200rmp. After extraction by the ionic liquid supported liquid membrane, the removal rates of cyanide in the wastewater were 80.95%, 89.60%, and 95.05%, respectively.

Embodiment 3

[0029] As shown in Figure 1, with 3.0mol / L sodium hydroxide solution as the analytical phase, three groups of cyanide wastewater with a concentration of 468.36mg / L in the material liquid phase (from a gold smelter in Henan Province, the pH was adjusted with sulfuric acid to 1, 3, 5), the stirring extraction time is 60min, and the stirring speed is 200rmp. After extraction by the ionic liquid support liquid membrane, the removal rates of cyanide in the wastewater are 72.95%, 87.90%, and 95.05%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com