A LED industry chip production wastewater treatment system and treatment method

A technology for waste water production and treatment system, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, general water supply saving, etc., can solve the problems of serious pollution, high cost, frequent cleaning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

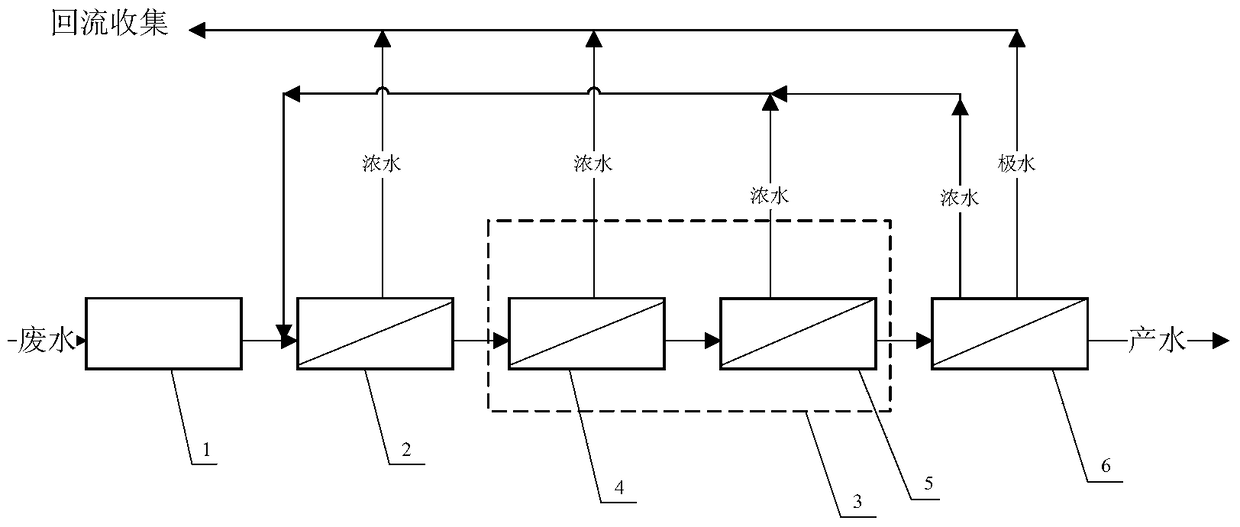

[0095] This embodiment provides a figure 1 The system shown:

[0096] A waste water treatment system for chip production in the LED industry, the system includes an advanced oxidation pretreatment device 1 , an ultrafiltration treatment device 2 , a reverse osmosis device 3 and an EDI desalination device 6 connected in sequence.

[0097] Wherein, a security filter is arranged in front of the advanced oxidation pretreatment device 1, and the pore diameter of the filter element in the security filter is 8 μm.

[0098] The advanced oxidation pretreatment device 1 includes an advanced oxidation reactor and a ceramic membrane filter. Among them, the advanced oxidation reactor includes UV / O 3 A catalytic reactor and a three-phase separation chamber; the ceramic membrane treatment device includes a ceramic membrane filter and a backwashing device.

[0099] The UV / O 3 The power of the ultraviolet light source in the catalytic reactor is 45W.

[0100] The UV / O 3 The solid-phase c...

Embodiment 2

[0110] In addition to the pore size of the filter element in the security filter is 10μm, UV / O 3 The power of the ultraviolet light source in the catalytic reactor is 40W, the particle size of the photosensitive semiconductor catalyst is 20-30nm, the molecular weight cut-off of the ultrafiltration membrane in the ultrafiltration membrane module is 20,000Da fine suspended matter, the filtration accuracy is 10nm, and the material is polypropylene , the operating temperature of the ultrafiltration treatment device 2 is 15°C, the transmembrane pressure difference is 0.05MPa, the operation of the reverse osmosis device 3 is stable at 15°C, the working pressure is 1.5MPa, and the wavelength of the mercury lamp in the ultraviolet sterilizing device is 180nm. The structure of other devices and the connection mode of each device are the same as those in Embodiment 1.

Embodiment 3

[0112] In addition to the pore size of the filter element in the security filter is 5μm, UV / O 3 The power of the ultraviolet light source in the catalytic reactor is 65W, the particle size of the photosensitive semiconductor catalyst is 90-100nm, the molecular weight cut-off of the ultrafiltration membrane in the ultrafiltration membrane module is 30,000Da fine suspended matter, the filtration accuracy is 20nm, and the material is polypropylene , the operating temperature of the ultrafiltration treatment device 2 is 40°C, the transmembrane pressure difference is 0.15MPa, the operation of the reverse osmosis device 3 is stable at 45°C, and the working pressure is 3.0MPa, and the wavelength of the mercury lamp in the ultraviolet sterilization device is 190nm. The structure of other devices and the connection mode of each device are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com