Preparation, preparation method and uses thereof

A preparation and liquid preparation technology, applied in anti-inflammatory agents, therapeutic nebulizers, non-central analgesics, etc., can solve problems such as rapid relief, and achieve the effects of promoting recovery, reducing the chance of infection, and eliminating tinnitus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

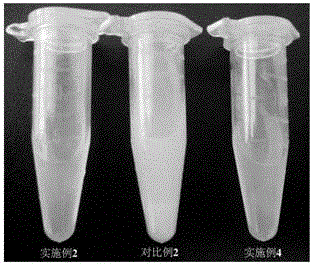

Image

Examples

preparation example Construction

[0086] Simultaneously, the present invention also provides the preparation method of above-mentioned preparation, comprise:

[0087] S1. Disperse the liquid surfactant in 40-60KHZ ultrasound for 1-3min;

[0088] S2. Under stirring conditions with a rotation speed of 3000 rpm or more, uniformly mix the liquid surfactant and the solvent to form a liquid formulation composition in which droplets containing the surfactant are dispersed in the solvent, and the surface tension of the liquid formulation composition is Less than 60mN / m, the absolute value of zeta potential is above 15mV;

[0089] S3. Put the above-mentioned liquid preparation composition into a container; the container is a sprayer or a dropper or an anti-pollution sprayer or dropper. .

[0090] In the above-mentioned preparation method, for the surfactant, the specific materials that can be used are as mentioned above, which can be lecithin, sterol, pulmonary surfactant, poloxamer, dipalmitoylphosphatidylcholine, c...

Embodiment 1

[0121] This example is used to illustrate the formulation disclosed in the present invention and its preparation method.

[0122] Weigh 2.38 g of hydrogenated phospholipids, 0.12 g of sterols, 0.4 g of methylparaben, 0.2 g of ethylparaben and 0.1 g of menthol and place them in a container. Add 1ml of absolute ethanol, dissolve with ultrasound (40KHZ), mix well under high-speed stirring (6000rpm), continue to add water to a final volume of 100ml, mix well, pour into a sprayer or dropper, and seal. After testing the quality parameters such as appearance properties, loading capacity, main component content, per spray volume (or per drop volume), microbial limit, etc., it is packaged after meeting the requirements, and it is ready.

[0123] The surface tension of the final product was detected by an automatic surface tension tester (USKino, A601) to be 48.851mN / m. The particle size distribution of the product was measured with a laser particle size analyzer Mastersizer 2000 (Malv...

Embodiment 2

[0126] This example is used to illustrate the formulation disclosed in the present invention and its preparation method.

[0127] Weigh 2.35g of soybean lecithin, 0.15g of poloxamer, 0.08g of vitamin E and 0.5g of phenylethyl alcohol and place them in a container. Add 1ml of absolute ethanol, dissolve with ultrasound (40KHZ), stir evenly at high speed (6000rpm), continue to add water to a final volume of 100ml, mix evenly, pour into a sprayer or dropper, and seal. After testing the quality parameters such as appearance properties, loading capacity, main component content, per spray volume (or per drop volume), microbial limit, etc., it is packaged after meeting the requirements, and it is ready.

[0128] The surface tension of the final product was detected by an automatic surface tension tester (USKino, A601) to be 16.252mN / m. The particle size distribution of the product was measured by a laser particle size analyzer Mastersizer 2000 (Malvern Instruments Ltd, UK), and the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume average particle size | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

| Volume average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com