Reverse flotation de-ashing method for lignite

A technology of reverse flotation and lignite, which is applied in the field of flotation to remove ash in lignite and reverse flotation deashing of lignite, which can solve the problems of large amount of collector, large amount of inhibitor, and high ash content of clean coal, so as to reduce flotation Clean coal ash content, environmental protection selective adsorption, improve the effect of poor surface electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

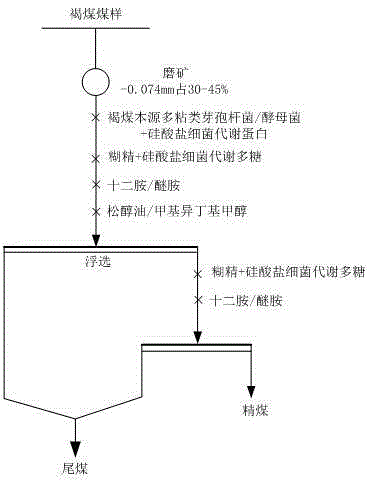

Method used

Image

Examples

Embodiment 1

[0027] A lignite with ash content of 14.26% and moisture content of 22.20% weighed 100g of a coal sample that was ground to -0.074mm and accounted for 36.4% and placed it in a 1LXFD hanging tank flotation machine, added distilled water to 1L, and then added Paenibacillus polymyxa 3×10 6 cells / cm 3 1. Silicate bacterial metabolic protein 15g / t, stirring at 1750r / min for 3min, adding collector dodecylamine 200g / t and stirring for 5min, scraping flotation for 5min; then adding inhibitor dextrin 100g / t, silicic acid Halobacteria metabolizes polysaccharides at 50g / t. After stirring for 5 minutes, add the collector dodecylamine in an amount of 50g / t. After stirring for 3 minutes, flotation and scrape for 5 minutes.

[0028] The above silicate bacterial metabolic protein was obtained by adding analytically pure ammonium sulfate to the supernatant obtained by centrifuging the silicate bacterial culture solution at a speed of 6000r / min to saturation, vibrating at a constant temperature...

Embodiment 2

[0030] Example 2: A lignite with ash content of 42.96%, moisture content of 28.84%, weighed 100g of a coal sample that was ground to -0.074mm and accounted for 42.7% and placed it in a 1LXFD hanging tank flotation machine, added distilled water to 1L, and then added yeast 9× 10 6 cells / cm 3 , Silicate bacterial metabolic protein 25g / t, stirring at 1750r / min for 3min, adding collector ether amine 800g / t and stirring for 5min, terpineol oil 20g / t, stirring for 3min, flotation scraping and foaming for 5min; then adding inhibitor 500g / t dextrin, 60g / t polysaccharide metabolized by silicate bacteria, 100g / t collector ether amine was added after stirring for 5 minutes, flotation and scraping for 5 minutes after stirring for 3 minutes.

[0031] The results of this embodiment are: the yield of flotation clean coal is 34.5%, the ash content is 15.37%, and the recovery rate of lignite is 65.54%. While conventional flotation clean coal has the same ash content, the recovery rate is onl...

Embodiment 3

[0033] A lignite with ash content of 15.19% and moisture content of 19.90% weighed 100g of a coal sample that was ground to -0.074mm and accounted for 32.5% and placed it in a 1LXFD hanging tank flotation machine, added distilled water to 1L, and then added yeast 2×10 6 cells / cm 3 1. Silicate bacterial metabolic protein 10g / t, stirring at 1750r / min for 3min, adding collector ether amine 800g / t and stirring for 5min, methyl isobutyl carbinol 30g / t, stirring for 3min, flotation scraping for 5min; Then add inhibitor dextrin 500g / t, silicate bacterial metabolic polysaccharide 40g / t, stir for 5 minutes, add collector dodecylamine dosage 50g / t, stir for 3 minutes, then flotation and scrape for 5 minutes.

[0034] The results of this embodiment are: the yield of flotation clean coal is 72.5%, the ash content is 8.11%, and the recovery rate of lignite is 65.29%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com