Preparing method for sulfur-doped graphene

A technology of sulfur-doped graphene and graphene, applied in the field of preparation of sulfur-doped graphene, can solve the problems of high equipment requirements, high reaction temperature, extremely toxic raw materials, etc., and achieves low reaction temperature, simple equipment, and production cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 300 mg of graphite oxide was ultrasonically stripped in 100 ml of deionized water for 1.5 hours to prepare a 3 mg / ml graphene oxide solution, and then 3 g of sodium sulfide was added to it, dispersed and mixed evenly by ultrasonication for 15 minutes, and hydrothermally reacted at 200°C for 15 hours , after cooling, wash with deionized water to remove excess sulfur-containing compounds, and obtain sulfur-doped graphene, wherein the atomic percentage of sulfur is 1.17%.

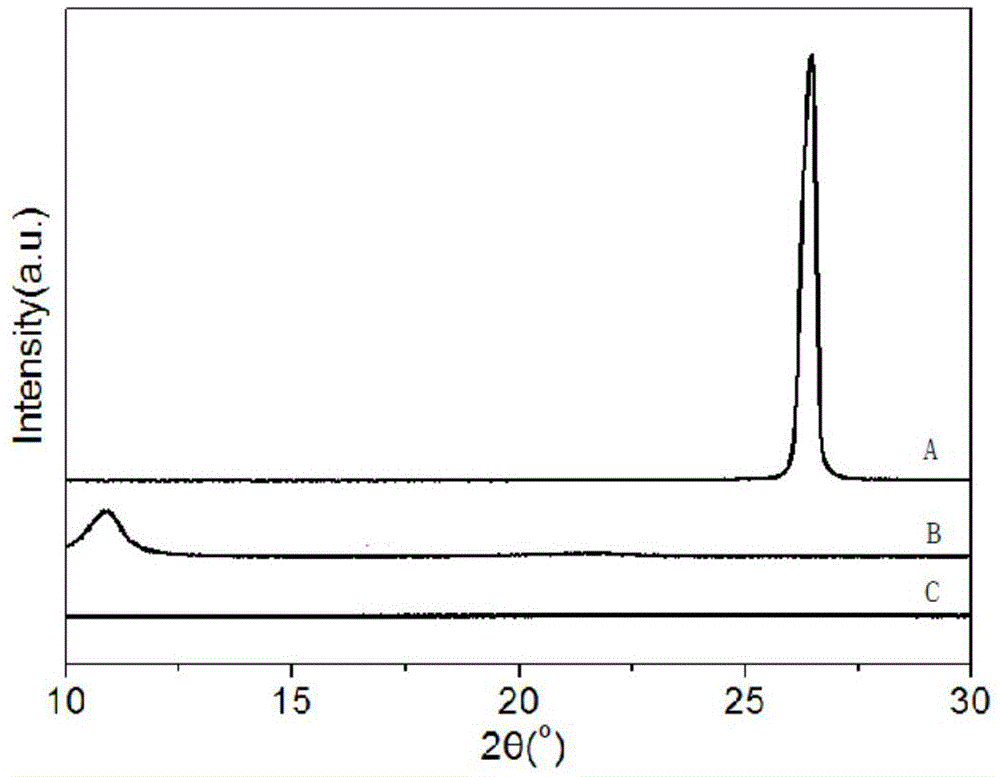

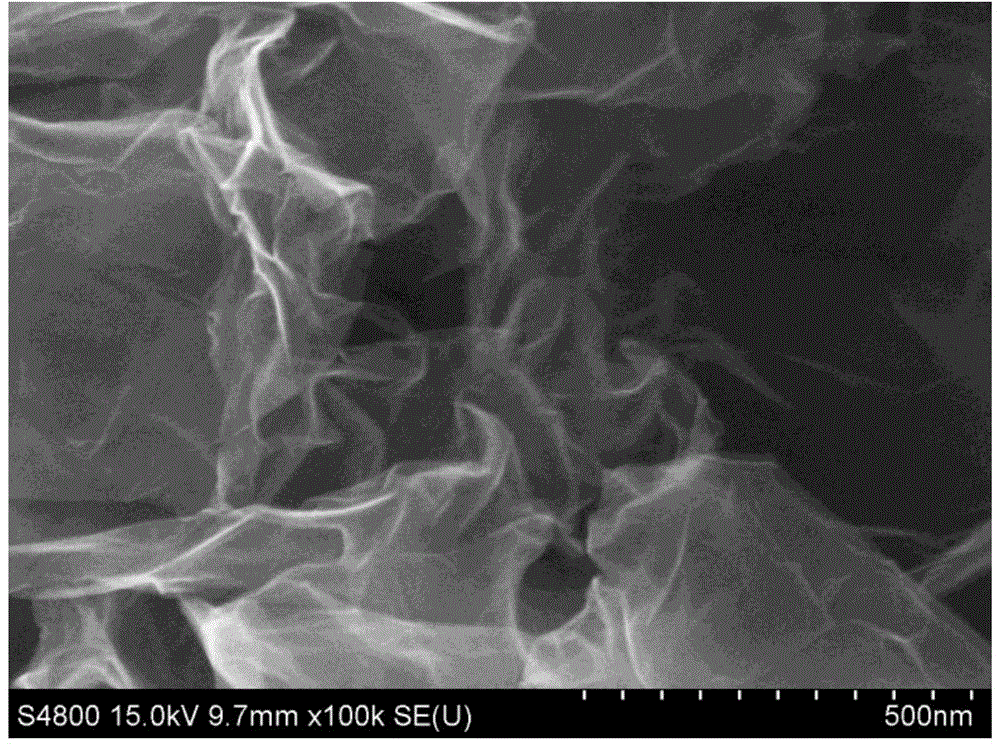

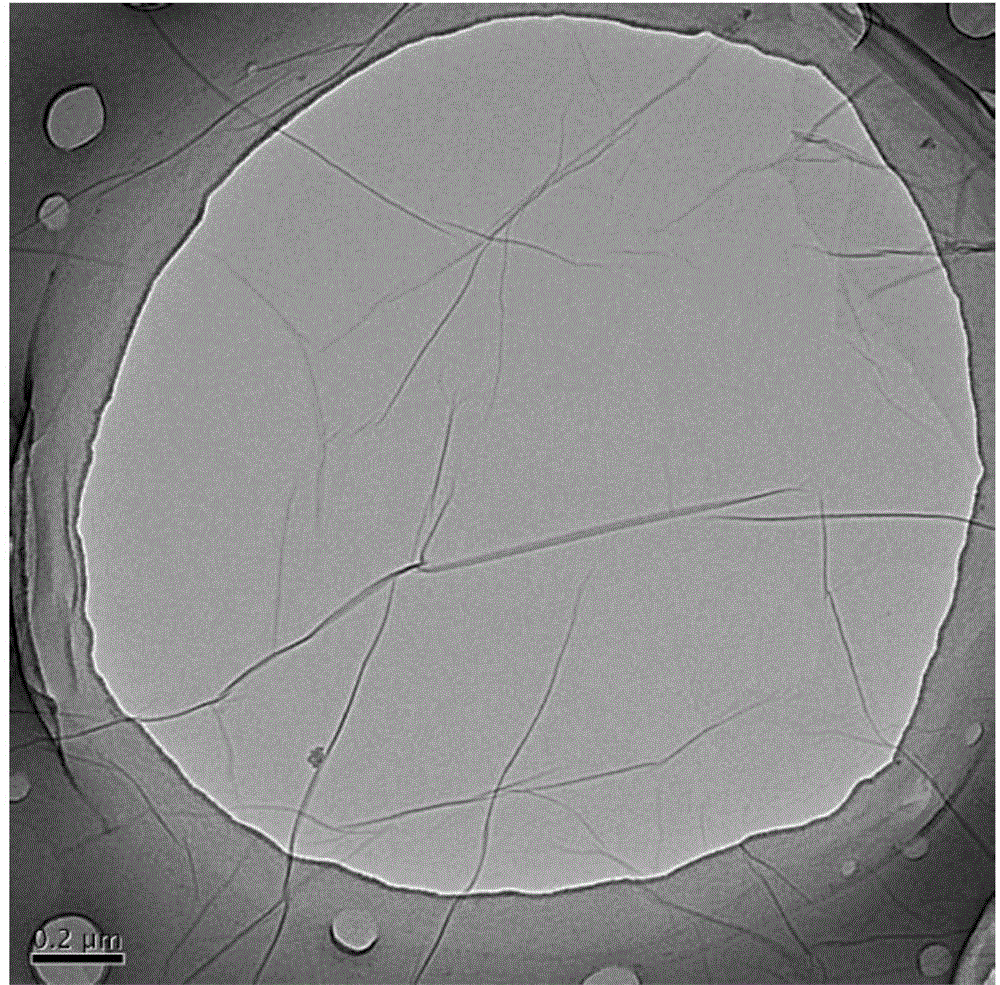

[0028] The obtained sulfur-doped graphene X-ray diffraction spectrum (XRD) figure, scanning electron microscope (SEM) figure, transmission electron microscope (TEM) figure, and X-ray photoelectron spectrum (XPS) figure see accompanying drawing, show that sulfur atom Already replaced carbon atoms into the graphene lattice.

Embodiment 2

[0030] 50 mg of graphite oxide was ultrasonically stripped in 100 ml of deionized water for 1 hour to prepare a 0.5 mg / ml graphene oxide solution, and then 2.5 g of sodium sulfide was added to it, dispersed and mixed evenly by ultrasonication for 10 minutes, and hydrothermally reacted at 180°C for 20 hours , after cooling, wash with deionized water to remove excess sulfur-containing compounds, and obtain sulfur-doped graphene, wherein the atomic percentage of sulfur is 0.94%.

[0031] The obtained sulfur-doped graphene X-ray diffraction spectrum (XRD) figure, scanning electron microscope (SEM) figure, transmission electron microscope (TEM) figure, and X-ray photoelectron spectrum (XPS) figure are similar to [embodiment 1] .

Embodiment 3

[0033] 500 mg of graphite oxide was ultrasonically stripped in 100 ml of deionized water for 2 hours to prepare a 5 mg / ml graphene oxide solution, and then 0.5 g of sodium sulfide was added to it, dispersed and mixed evenly by ultrasonication for 10 minutes, and hydrothermally reacted at 210°C for 8 hours , after cooling, wash with deionized water to remove excess sulfur-containing compounds, and obtain sulfur-doped graphene, wherein the atomic percentage of sulfur is 0.81%.

[0034] The obtained sulfur-doped graphene X-ray diffraction spectrum (XRD) figure, scanning electron microscope (SEM) figure, transmission electron microscope (TEM) figure, and X-ray photoelectron spectrum (XPS) figure are similar to 【Example 1】 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com