Cement reinforcing agent, preparation method, and application thereof

A technology for cement reinforcing agent and cement mortar, applied in the field of cement reinforcing agent and preparation, can solve the problems of affecting the mechanical strength of hardened cement slurry, reducing the rheological properties of freshly mixed cement slurry, affecting the effect of pozzolanic reaction, etc., and reducing free hydroxyl groups. number, the effect of improving composition and microstructure, good compatibility and adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of cement reinforcing agent comprises the following steps:

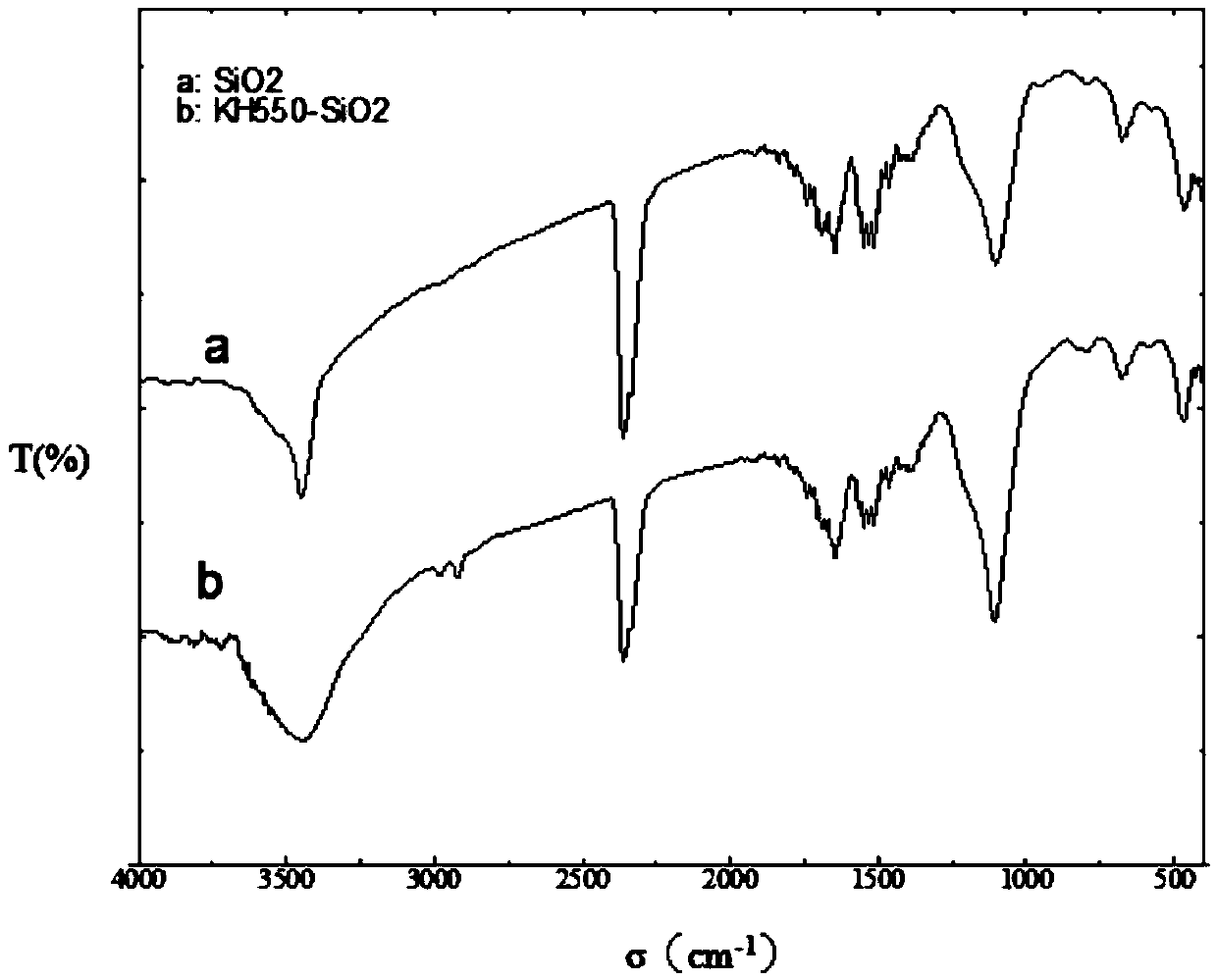

[0039](1) Fully disperse 100 parts by mass of wet-process silica in deionized water under the action of an anionic surfactant with a mass fraction of 1 to 2% relative to silica to form a uniform water phase reaction system, wherein the mass ratio of wet-process silica to deionized water is 1:5-12;

[0040] (2) Add the alcohol solution of silane coupling agent dropwise to the reaction system, the dropping rate is 4-7mL / min, the mass concentration of silane coupling agent / organic alcohol solution is 1.0-2.5g / g, the silane coupling agent alcohol The mass ratio of solution addition amount to wet process white carbon black is 1.11~1.56g / g;

[0041] (3) Keep the reaction system at 70-80°C for 3.5-4.5 hours to obtain modified wet-process silica;

[0042] (4) The modified wet-process silica is baked at 80°C for 12 hours to obtain the product.

[0043] Anionic surfactants include one of sodium...

example 1

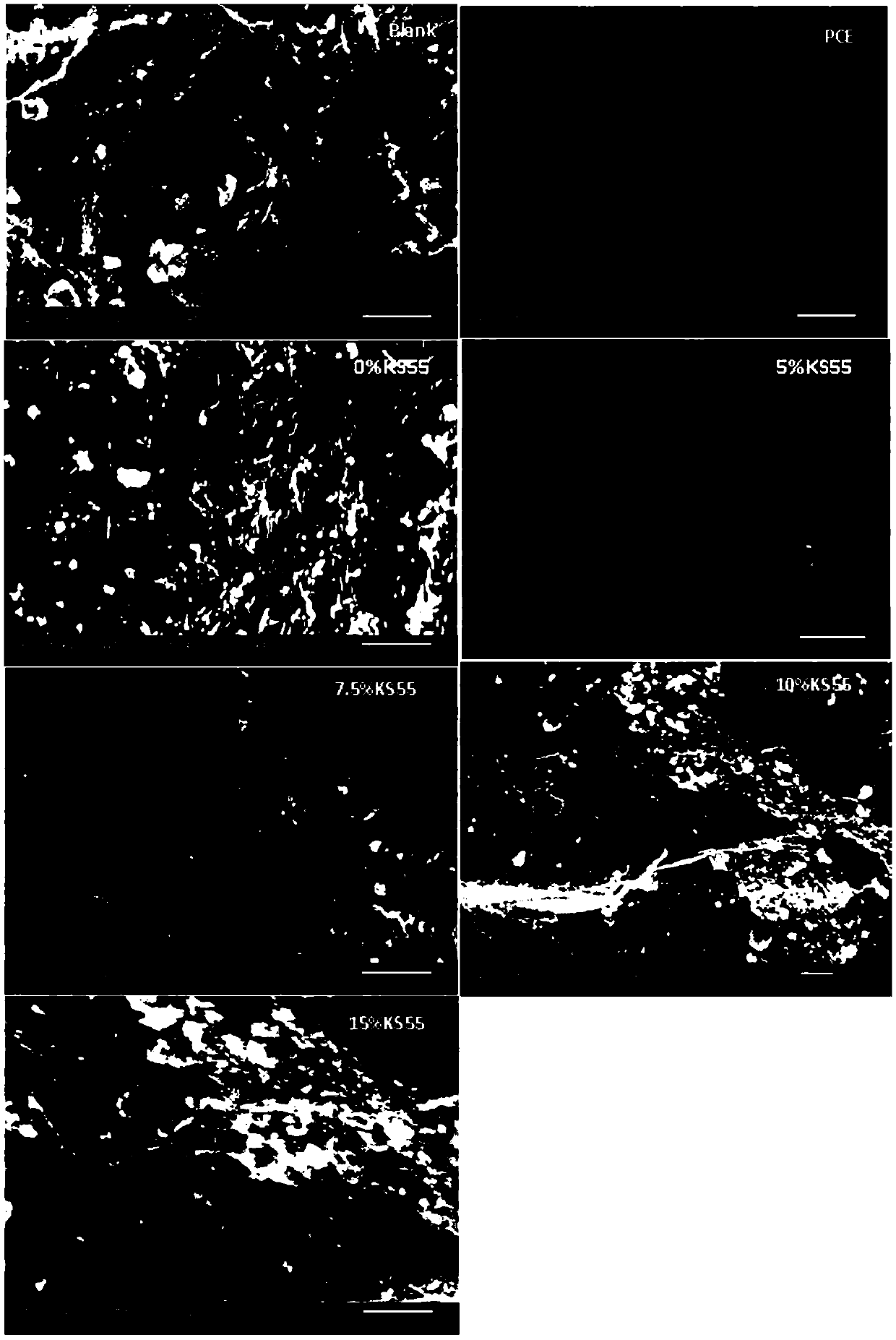

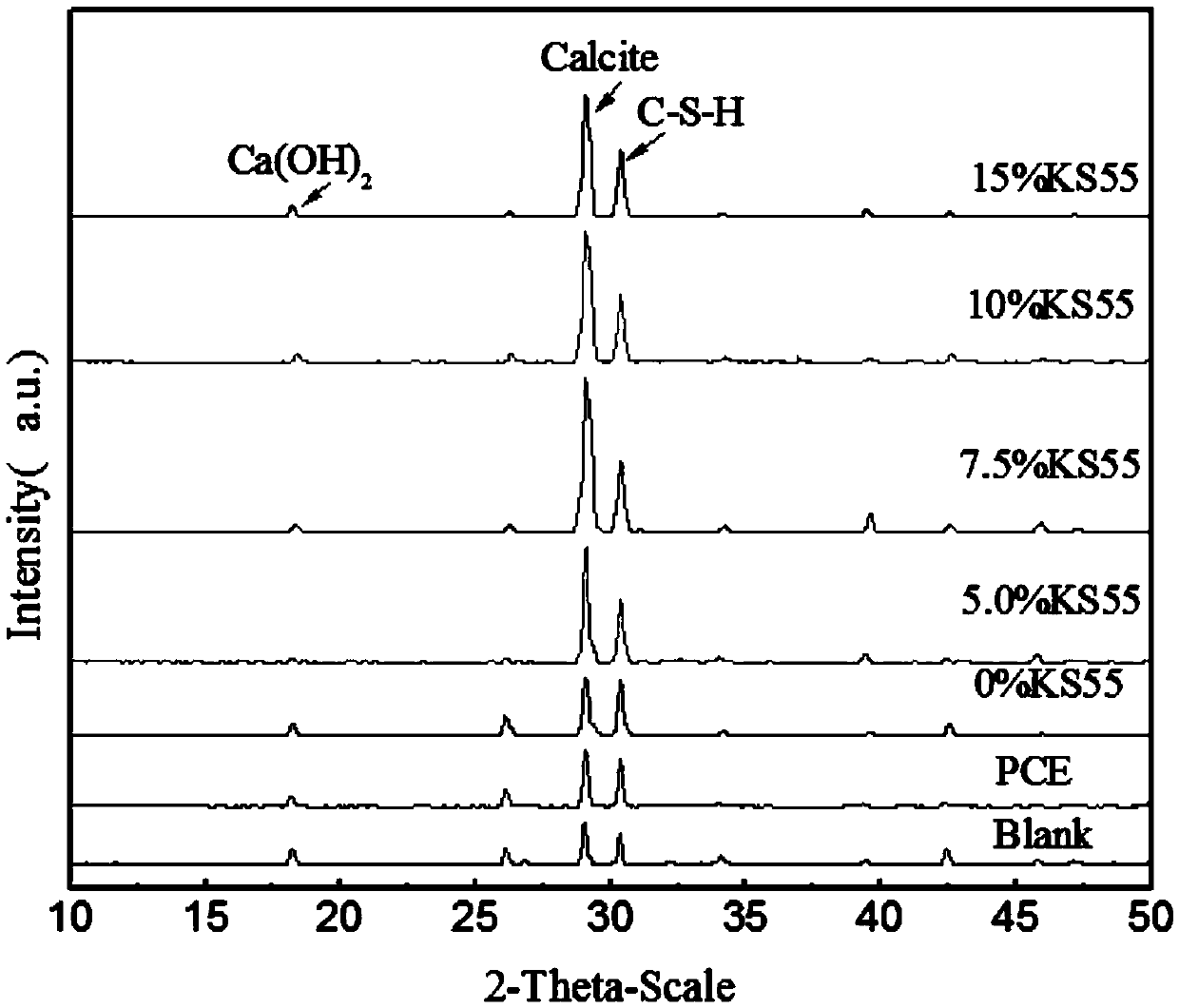

[0052] The mass parts of the raw materials for the preparation of the cement reinforcing agent of this example are composed as follows: relative to 100 parts by weight of wet-process silica, 750 parts of deionized water, 5 parts of aminopropyltriethoxysilane, dodecylsulfonic acid 1 part of sodium, 5 parts of ethanol;

[0053] Preparation Process:

[0054] (1) Fully disperse wet-process white carbon black in deionized water under the action of sodium dodecylsulfonate according to the formula quantity to form a uniform water phase reaction system;

[0055] (2) Dissolving aminopropyltriethoxysilane in ethanol to obtain an alcohol solution of aminopropyltriethoxysilane according to the formula quantity;

[0056] (3) Add the alcoholic solution of aminopropyltriethoxysilane dropwise to the water phase reaction system, the dropping speed is 4~7mL / min, the addition amount of the alcoholic solution of aminopropyltriethoxysilane is the same as that of wet process whitening The mass ra...

example 2

[0060] The difference between this example and Example 1 is that the mass parts of the raw materials for the preparation of the cement reinforcing agent are composed as follows: relative to 100 parts by weight of white carbon black, 800 parts of deionized water, 7.5 parts of aminopropyltriethoxysilane, dodecyl 1.2 parts of sodium sulfonate, 8.0 parts of ethanol;

[0061] The preparation process of this embodiment is the same as Product Example 1.

[0062] The cement reinforcing agent prepared in this example is named 7.5% KS55, and the physical properties of 7.5% KS55 are determined: DBP is 2.60mL·g -1 , with a density of 1.5513g·cm -3 , the number of surface hydroxyl groups is 1.87mM·g -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| oil absorption value | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| oil absorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com