Water-soluble carbon enzyme granule fertilizer and preparation method thereof

A technology of carbon enzyme granules and manufacturing methods, which is applied in the direction of potassium fertilizer, magnesium fertilizer, organic fertilizer, etc., can solve the problems of inability to add organic nutrients, unfavorable formation of aggregate structure, unreasonable ratio of nitrogen, phosphorus and potassium, etc., to improve crop quality , good water solubility, the effect of reducing the amount of fertilizer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

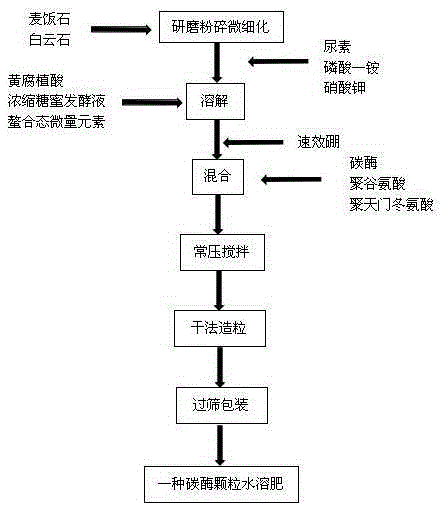

Image

Examples

Embodiment 1

[0026] A kind of carbon enzyme granular water-soluble fertilizer, comprising the following components in parts by weight:

[0027] 5 parts of medical stone, 3 parts of dolomite, 20 parts of urea, 10.5 parts of ammonium phosphate, 40 parts of potassium nitrate, 1 part of fulvic acid, 1 part of concentrated molasses fermentation liquid, 0.1 part of carbonase, 1 part of polyglutamic acid, 0.1 part of polyaspartic acid, 2 parts of chelated calcium, 0.5 part of chelated magnesium, 0.2 part of available boron, 0.2 part of chelated zinc, and 0.3 part of chelated iron.

[0028] A method for manufacturing carbon enzyme granular water-soluble fertilizer, comprising the following steps:

[0029] Step 1. According to the distribution ratio of each component described in claim 1, 5 parts of medical stone and 3 parts of dolomite are respectively ground with a grinder to 1500-2500 mesh for refinement;

[0030] Step 2. Add the medical stone powder and dolomite powder obtained in step 1, 20 p...

Embodiment 2

[0034] A kind of carbon enzyme granular water-soluble fertilizer, comprising the following components in parts by weight:

[0035] 6 parts of medical stone, 5 parts of dolomite, 20 parts of urea, 15 parts of ammonium phosphate, 35 parts of potassium nitrate, 5 parts of fulvic acid, 5 parts of concentrated molasses fermentation liquid, 0.1 part of carbonase, 1 part of polyglutamic acid, 0.1 part of polyaspartic acid, 2 parts of chelated calcium, 1 part of chelated magnesium, 0.5 part of available boron, 0.5 part of chelated zinc, and 0.5 part of chelated iron.

[0036] A method for manufacturing carbon enzyme granular water-soluble fertilizer, comprising the following steps:

[0037] Step 1. According to the distribution ratio of each component described in claim 1, 6 parts of medical stone and 5 parts of dolomite are respectively ground to 1500-2500 mesh with a grinder for refining treatment;

[0038] Step 2. Add the medical stone powder and dolomite powder obtained in step 1...

Embodiment 3

[0041] A kind of carbon enzyme granular water-soluble fertilizer, comprising the following components in parts by weight:

[0042] 10 parts of medical stone, 10 parts of dolomite, 16 parts of urea, 12 parts of ammonium phosphate, 32 parts of potassium nitrate, 10 parts of fulvic acid, 3 parts of concentrated molasses fermentation liquid, 0.1 part of carbonase, 1 part of polyglutamic acid, 0.1 part of polyaspartic acid, 2 parts of chelated calcium, 1 part of chelated magnesium, 0.5 part of available boron, 0.3 part of chelated zinc, and 0.3 part of chelated iron.

[0043] A method for manufacturing carbon enzyme granular water-soluble fertilizer, comprising the following steps:

[0044] Step 1. According to the distribution ratio of each component described in claim 1, 10 parts of medical stone and 10 parts of dolomite are respectively ground to 1500-2500 mesh with a grinder for refinement;

[0045]Step 2. Add the medical stone powder and dolomite powder obtained in step 1, 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com