Graphene-polypyrrole composite aerogel and preparation method and application thereof

A composite aerogel and composite hydrogel technology, applied in the field of nanoporous materials, can solve the problems of inhibiting the high specific surface area of graphene, unfavorable application of graphene aerogel, not in line with energy saving and environmental protection, etc. production, high specific capacitance properties, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] As one of typical implementation cases, a preparation method of graphene-polypyrrole composite airgel may comprise the following steps:

[0045] (1) In the acidic aqueous solution, graphene oxide is added, mechanically stirred and ultrasonically dispersed until a uniform graphene oxide solution is formed; the graphene oxide solution exists stably for at least 1-300 days;

[0046] (2) Put the graphene oxide aqueous solution at room temperature, add pyrrole monomer, stir mechanically (or magnetically) for 1 to 900 minutes, ultrasonically for 0.5 to 200 minutes, and then stand at room temperature for 1 to 28 days to obtain graphene - polypyrrole composite hydrogel;

[0047] (3) Obtaining graphene-polypyrrole composite airgel by freeze-drying or supercritical drying the graphene-polypyrrole hydrogel.

[0048] Wherein, graphene oxide can be prepared by Hummers chemical method.

[0049] The graphene-polypyrrole composite airgel of the present invention can be used as an ele...

Embodiment 1

[0053] Example 1: The graphene oxide dispersion liquid was configured into a solution of 8 mg / mL, stirred for 20 minutes, and ultrasonicated for 30 minutes to obtain a uniformly dispersed graphene oxide solution; 10 mL of the solution was taken, and 16.5 μL of pyrrole monomer was added thereto, Stir for 30 minutes, and then sonicate for 15 minutes; the obtained uniformly mixed dispersion of graphene oxide and pyrrole is left at room temperature for 7 days to obtain a graphene-polypyrrole composite hydrogel. Dissolving and replacing the obtained hydrogel with ethanol to obtain a graphene-polypyrrole composite alcohol gel, and then drying the graphene-polypyrrole composite alcohol gel through supercritical carbon dioxide to obtain a graphene-polypyrrole composite airgel. The ratio of the airgel starting material graphene oxide to pyrrole monomer is 5:1, which is denoted as GP5.

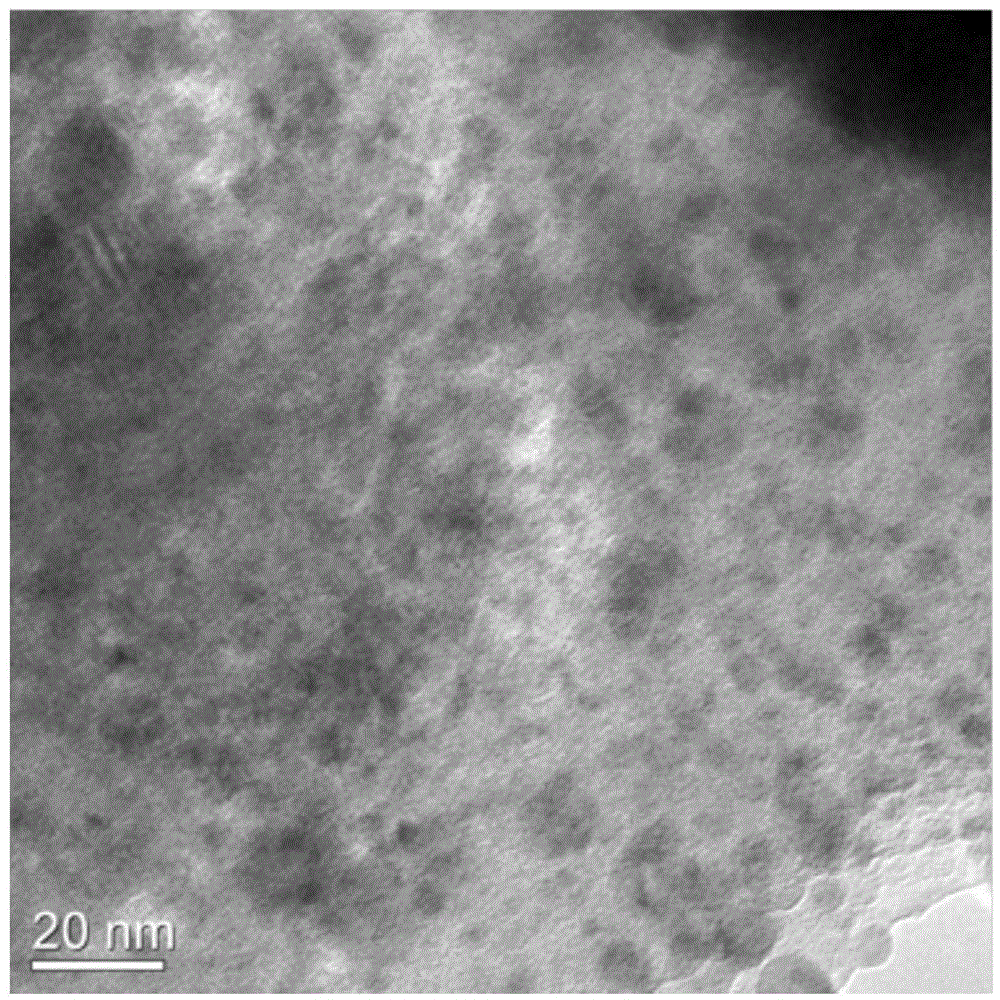

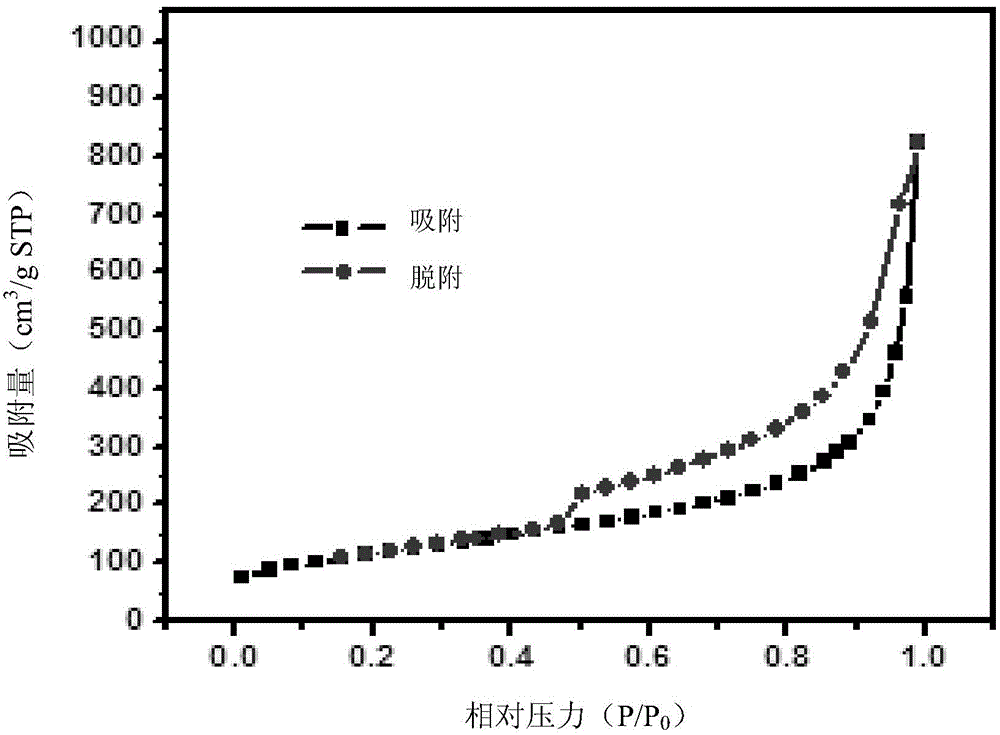

[0054] The structure and performance parameters of the graphene-polypyrrole composite airgel (GP5) o...

Embodiment 2

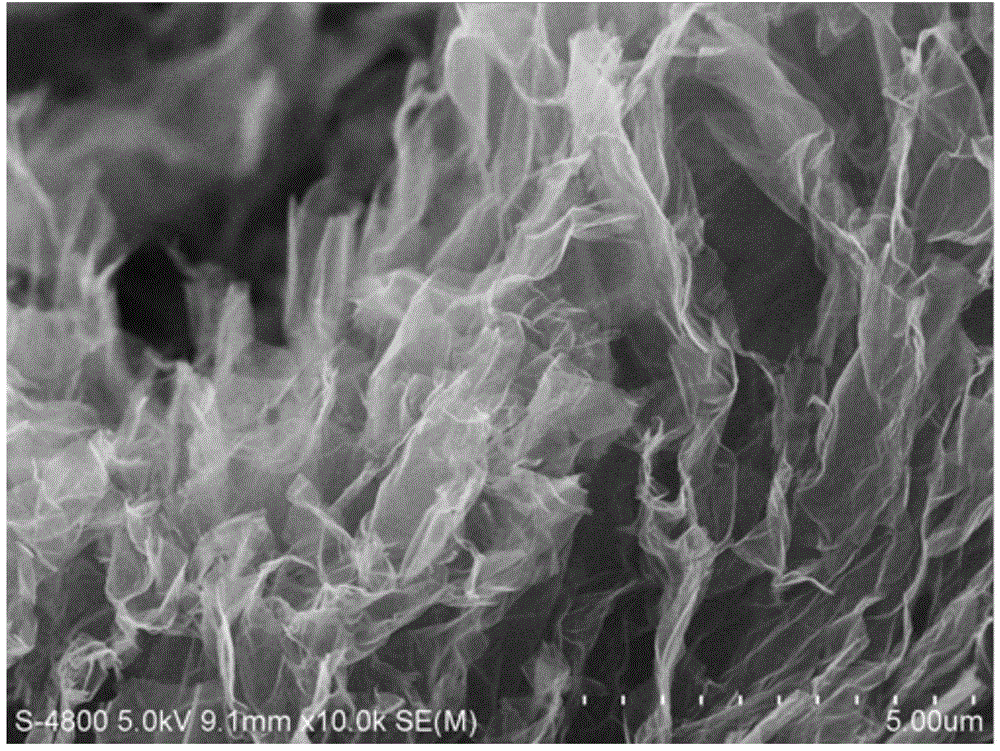

[0055] Example 2: The graphene oxide dispersion liquid was configured into a solution of 8 mg / mL, stirred for 20 minutes, and ultrasonicated for 30 minutes to obtain a uniformly dispersed graphene oxide solution; 10 mL of the solution was taken, and 27.5 μL of pyrrole monomer was added thereto, Stir for 20 minutes, and then sonicate for 20 minutes; the obtained uniformly mixed graphene oxide and pyrrole dispersion is left at room temperature for 7 days to obtain a graphene-polypyrrole composite hydrogel. Dissolving and replacing the obtained hydrogel with ethanol to obtain a graphene-polypyrrole composite alcohol gel, and then drying the graphene-polypyrrole composite alcohol gel through supercritical carbon dioxide to obtain a graphene-polypyrrole composite airgel. The ratio of the airgel starting material graphene oxide to pyrrole monomer is 3:1, which is denoted as GP3. Figure 1a It is the scanning electron micrograph of the graphene-polypyrrole composite airgel that makes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com