graphite phase c 3 no 4 Preparation method of carbon nanotube composite counter electrode

A carbon nanotube composite, C3N4 technology, applied in the field of solar cells, can solve the problems of low electrical conductivity, low photoelectric conversion efficiency of dye-sensitized solar cells, and reduced electron transport rate, etc. the transfer and the effect of improving the catalytic surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

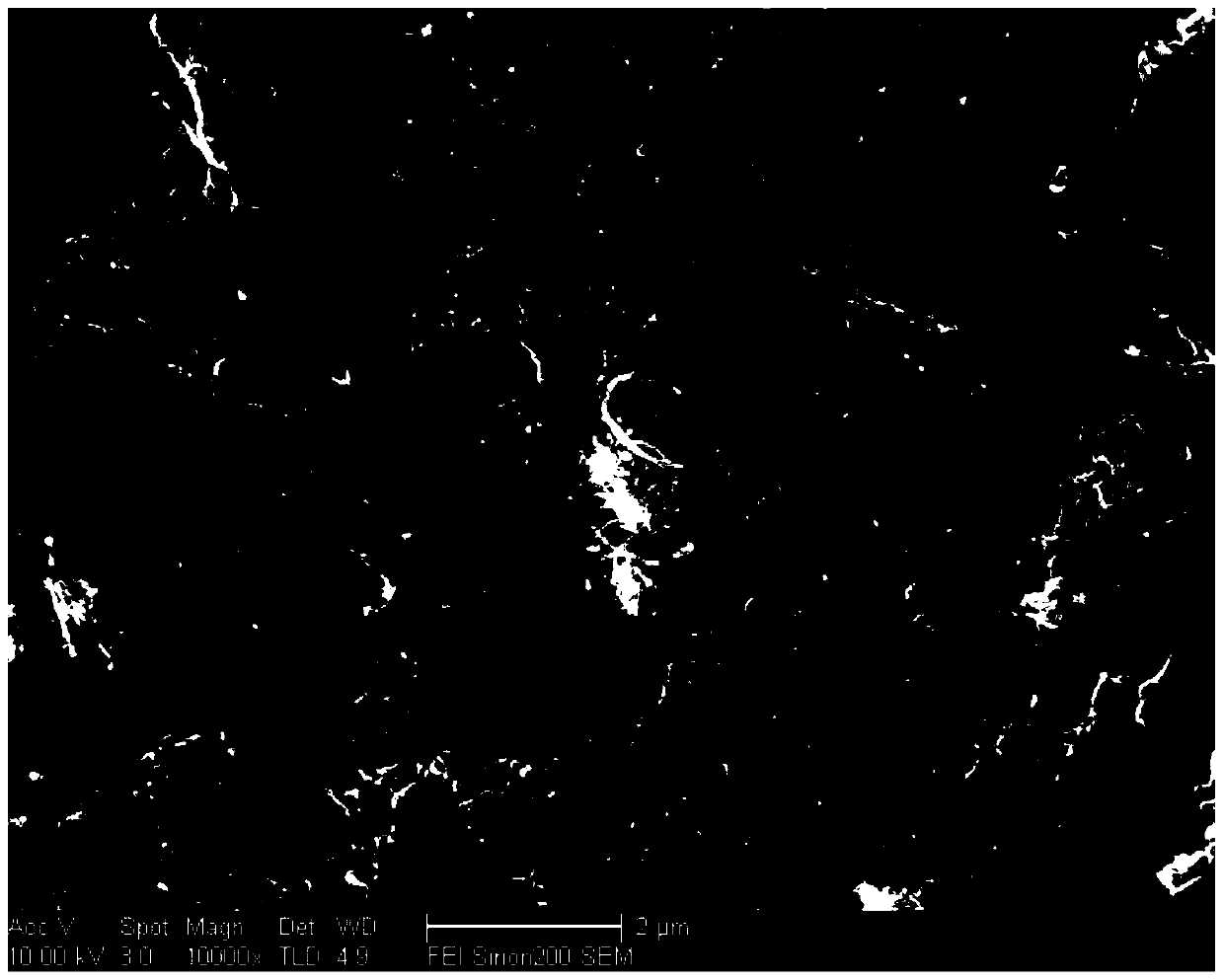

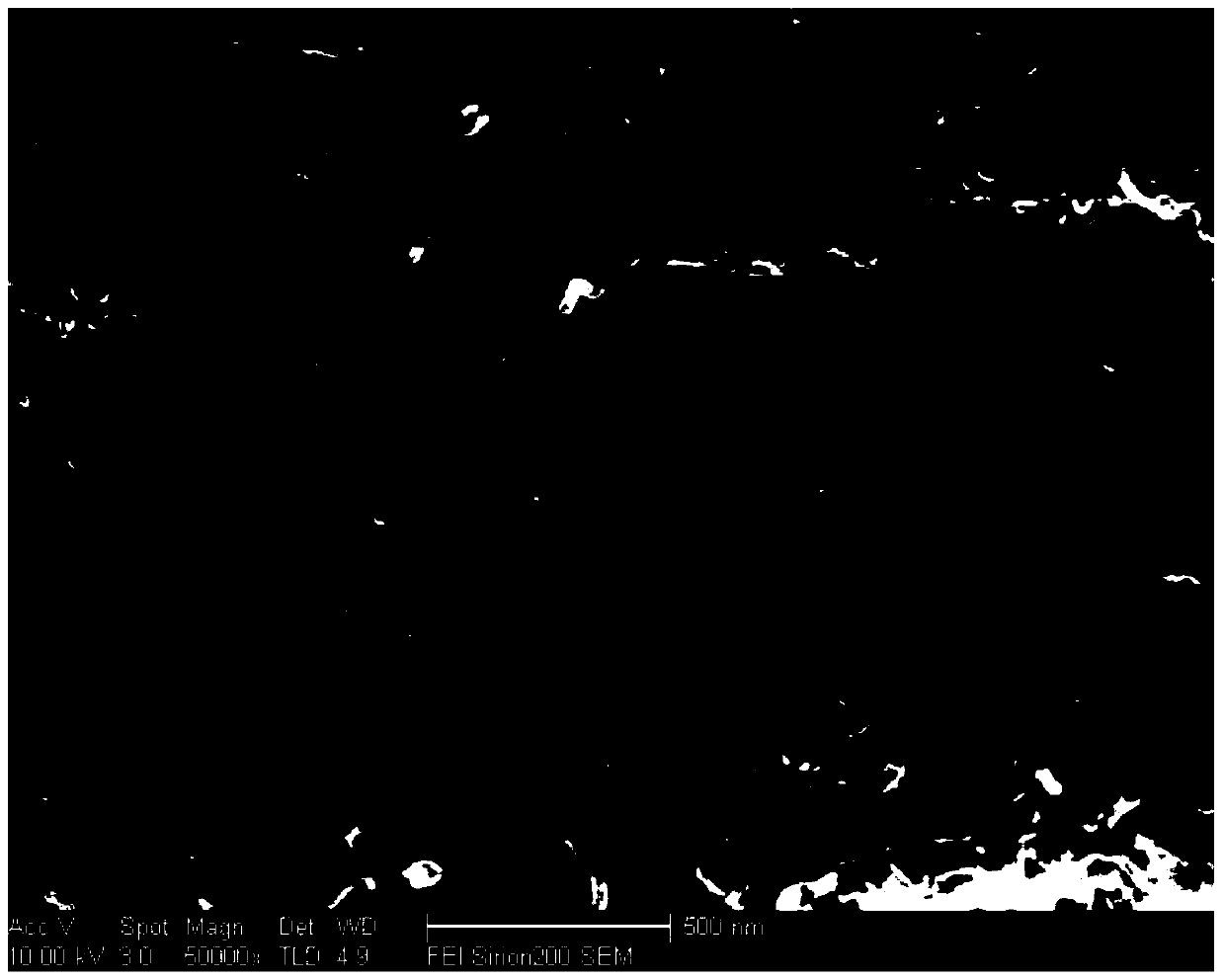

Image

Examples

preparation example Construction

[0028] A kind of graphite phase C that the present invention relates to 3 N 4 / The preparation method of carbon nanotube composite counter electrode, comprises steps as follows:

[0029] (1) Add carbon nanotubes into cyanamide or dicyandiamide solution, heat and reflux for 1 to 6 hours, preferably at a heating temperature of 90 to 100°C, then filter and dry under vacuum to obtain cyanide adsorbed on the surface Carbon nanotubes of amine or dicyandiamide; the concentration of the cyandiamide or dicyandiamide solution is 20-50wt%, and the weight of cyandiamide or dicyandiamide in the carbon nanotubes and cyandiamide or dicyandiamide solution The ratio is 1:10~1:30.

[0030] (2) Put the carbon nanotubes prepared in step (1) into a tubular furnace, control the heating rate to 2-6°C / min, heat up to 500-600°C, and heat-treat for 2-6 hours in a nitrogen atmosphere; cool to room temperature, the graphitic phase C 3 N 4 / carbon nanotube composites.

[0031] (3) The composite mat...

Embodiment 1

[0036] A kind of graphite phase C that the present invention relates to 3 N 4 / The preparation method of carbon nanotube composite counter electrode, comprises steps as follows:

[0037] (1) Add 200mg of carbon nanotubes into 12mL, 50wt% cyanamide solution, heat and reflux at 100°C for 1 hour, then filter, and dry at 60°C under vacuum to obtain carbon nanotubes with cyanamide adsorbed on the surface .

[0038] (2) Put the carbon nanotubes prepared in step (1) into a tube furnace, control the heating rate to 2° C. / min, raise the temperature to 500° C., and perform heat treatment in a nitrogen atmosphere for 6 hours; cool to room temperature to obtain a graphite phase C 3 N 4 / carbon nanotube composites.

[0039](3) Disperse the composite material obtained in step (2) into 10 mL of n-butanol solvent, then add butyl titanate, and form a uniform dispersion by stirring. The mass fraction of the composite material in the dispersion liquid is 20 parts, and the mass fraction of...

Embodiment 2

[0043] A kind of graphite phase C that the present invention relates to 3 N 4 / The preparation method of carbon nanotube composite counter electrode, comprises steps as follows:

[0044] (1) Add 500mg of carbon nanotubes to 25mL, 20wt% cyanamide solution, heat and reflux at 90°C for 6 hours, then filter, and dry at 60°C under vacuum to obtain carbon nanotubes with cyanamide adsorbed on the surface .

[0045] (2) Put the carbon nanotubes prepared in step (1) into a tube furnace, control the heating rate to 6° C. / min, raise the temperature to 600° C., and heat-treat for 2 hours under a nitrogen atmosphere; cool to room temperature to obtain a graphite phase C 3 N 4 / carbon nanotube composites.

[0046] (3) Disperse the composite material obtained in step (2) into 10 mL of isopropanol solvent, then add titanium isopropoxide, and form a uniform dispersion by grinding. The mass fraction of the composite material in the dispersion is 60 parts, and the mass fraction of the add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com