Germanium antimony selenium infrared glass with antireflection film and preparation method thereof

A technology of infrared glass and anti-reflection film, which is applied to optical components, optics, instruments, etc., can solve the problems of excessive film material, film layer shedding, and great difference in physical and chemical properties, and meet the requirements of transmission and low residual reflectivity , good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

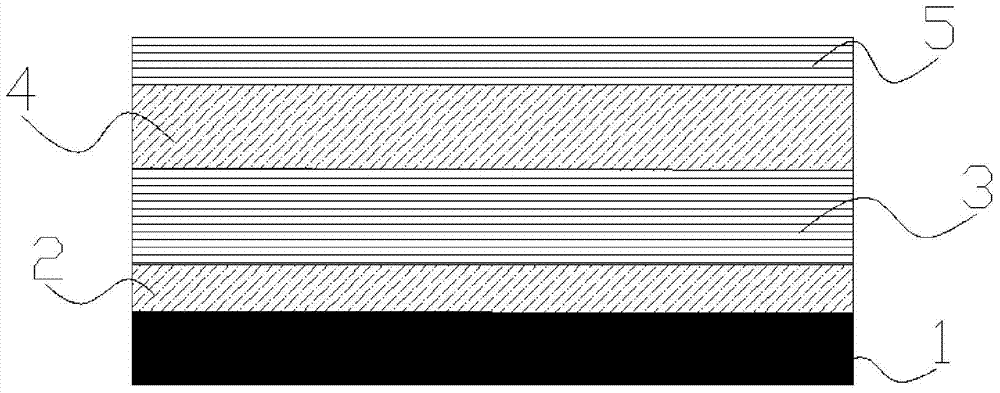

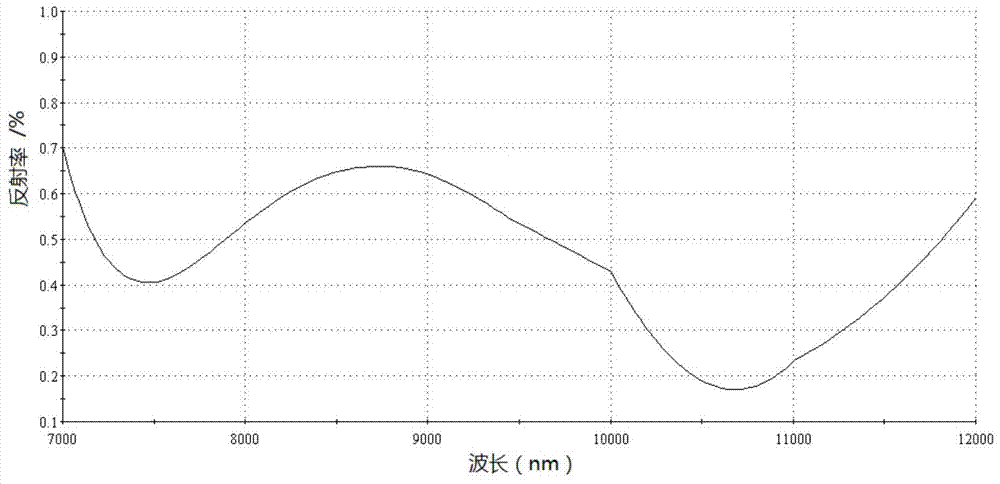

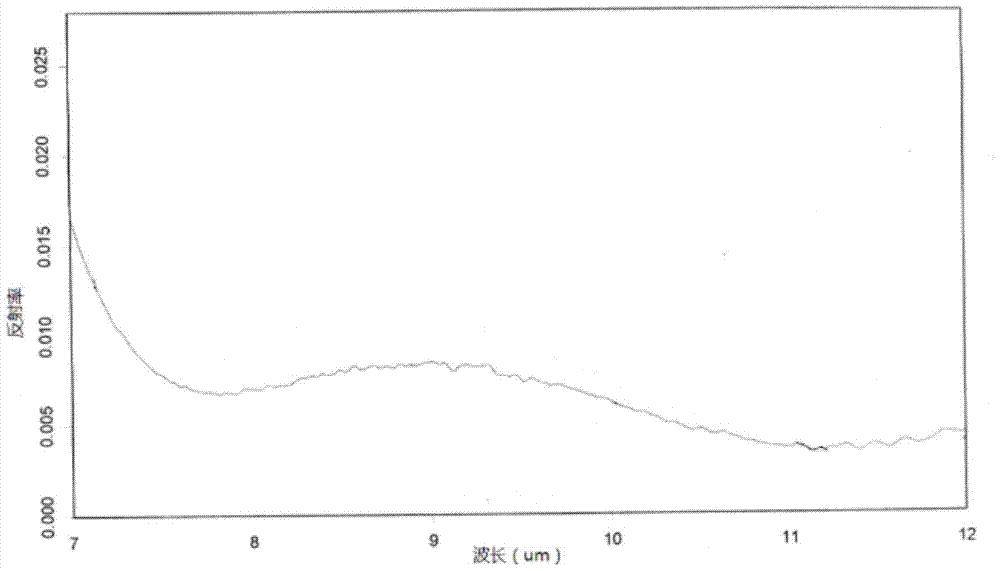

Method used

Image

Examples

Embodiment 1

[0037] The preparation method of the germanium antimony selenium infrared glass with antireflection coating comprises the following steps:

[0038] (1) Cleaning and preheating: Ultrasonic cleaning is performed on the infrared glass substrate with a mixture of acetone and alcohol ether, the cleaning time is 15 minutes each, and finally, the substrate is dried in an oven; after drying, quickly clamp the substrate Place in a vacuum chamber and draw a vacuum. Vacuum up to 5.0×10 -3 pa, adjust the output voltage of the baking lamp, the heating rate is: room temperature -60°C, 30min, 60°C-100°C, 30min, after reaching the temperature, keep warm for 1.2h.

[0039] What needs to be explained here is that germanium antimony selenium infrared glass is a brittle material, and gradient heating can prevent glass breakage caused by drastic temperature changes.

[0040] (2) Ion-assisted cleaning, turn on the ion source, fill the volume of argon gas with 35 sccm, and the pressure of the vacu...

Embodiment 2

[0053] The infrared glass substrates were ultrasonically cleaned with acetone and alcohol ether mixtures for 13 minutes and 16 minutes respectively, and finally, the substrates were dried in an oven.

[0054] After the drying is completed, the quick clamping substrate is put into the vacuum chamber, and the vacuum is drawn; the vacuum reaches 8.0×10 -3 pa, adjust the output voltage of the baking lamp, and the heating rate is: room temperature-60°C, 30min, 60°C-120°C, 40min; after reaching the temperature, keep warm for 1.5 hours.

[0055] Filled with argon gas 40sccm, the pressure of the vacuum chamber is 8.0×10 -3 pa, turn on the ion source, and adjust the ion source parameters as follows: anode voltage 100V, anode current 2A, workpiece disk rotation speed 10rpm.

[0056] Plating the first YbF 3 film, the vacuum chamber pressure during evaporation is 1.0×10 -2 pa, the deposition rate is 0.15nm / s, the crystal oscillator is used to control the deposition rate, the deposition...

Embodiment 3

[0065] The infrared glass substrates were ultrasonically cleaned with acetone and alcohol ether mixtures for 18 minutes and 12 minutes respectively, and finally, the substrates were dried in an oven.

[0066] After the drying is completed, the quick clamping substrate is put into the vacuum chamber, and the vacuum is drawn; the vacuum reaches 1.0×10 -2 pa, adjust the output voltage of the baking lamp, and the heating rate is: room temperature-60°C, 30min, 60°C-120°C, 40min; after reaching the temperature, keep warm for 1.5 hours.

[0067] Filled with argon gas 40sccm, the pressure of the vacuum chamber is 2.0×10 -2 pa, turn on the ion source, and adjust the ion source parameters as follows: anode voltage 150V, anode current 1A, workpiece disk rotation speed 20rpm.

[0068] Plating the first YbF 3 film, the vacuum chamber pressure during evaporation is 2.0×10 -2 pa, the deposition rate is 0.15nm / s, the deposition rate is controlled by a crystal oscillator, the deposition opt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com