Plasmon enhancement based electron emitting device and method with light enhancement/modulation

A technology of plasmon enhancement and optical modulation device, which is applied to the structure of electron emission electrode/cathode and optical resonant cavity, can solve the problems of inability to achieve ultrafast electron source and low quantum efficiency of noble metal cathode, and achieve the improvement of electron emission. The effect of emission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

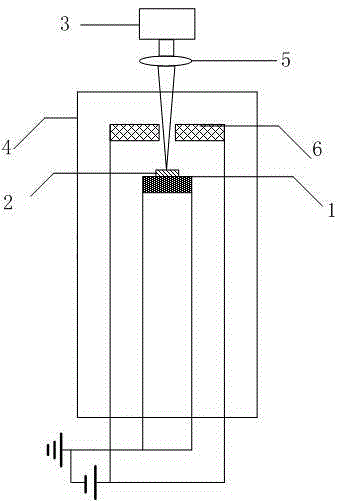

[0025] Example 1: A layer of carbon nanotubes is prepared by screen printing on the surface of the oxygen-free copper substrate, and then a composite cathode structure is formed after the golden triangular plate particle solution is deposited on the surface of the carbon nanotubes by a drop-coating method. according to figure 1 For packaging, the laser irradiates the surface of the composite cathode through the collimation system and the anode containing through holes. Due to the local field enhancement characteristics of the silver nanotriangular plate, a local field that is much greater than the incident laser light field will be formed on the surface of the composite cathode. Carbon nano Under the common potential barrier compression of the local field and the applied voltage, the tube will produce enhanced electron emission.

Embodiment 2

[0026] Example 2: A layer of carbon nanotube film is prepared by chemical vapor deposition on the surface of a silicon wafer containing an iron-nickel catalyst, and then gold nanoparticles are prepared on the surface of the carbon nanotube by evaporation and annealing to form a composite cathode structure. The cathode structure according to figure 1 For packaging, the laser irradiates the surface of the composite cathode through the collimation system and the anode containing through holes. Due to the local field enhancement characteristics of gold nanoparticles, a local field that is much greater than the incident laser light field will be formed on the surface of the composite cathode. Under the common potential barrier compression of the local field and the applied voltage, the tube will produce enhanced electron emission.

Embodiment 3

[0027] Embodiment 3: transfer a layer of graphene material on the surface of the ITO conductive glass substrate, then use the method of spin coating to spin coat a layer of gold nano-star solution on the graphene surface, and dry to form a composite cathode structure of graphene and gold nano-star . The cathode structure according to figure 1 For packaging, the laser passes through the collimation system and the anode containing through holes to irradiate the surface of the composite cathode. Due to the local field enhancement characteristics of gold nanostars, a local field that is much greater than the intensity of the incident laser light field will be formed on the surface of the composite cathode. Electron emission will occur under the common potential barrier compression of the local field and the applied voltage. By changing the intensity of the incident laser, changing the local electric field of the metal nanostructure and the electric field around the graphene, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com