Device and method for recycling petroleum and phenol from oilfield industry wastewater and treating and regenerating wastewater

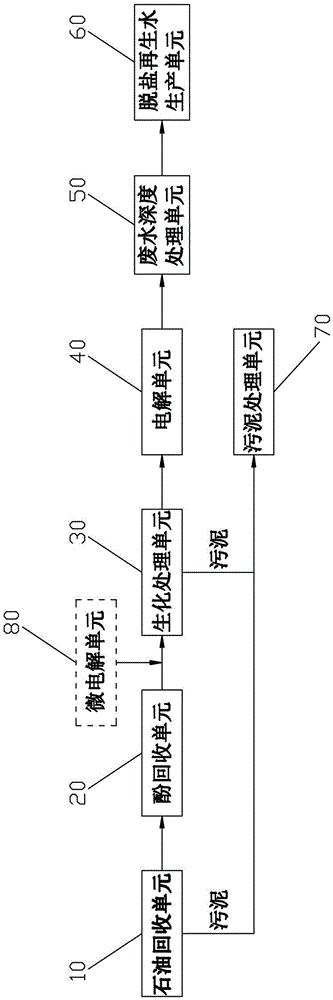

A technology for oil production wastewater and wastewater treatment, which is applied in the fields of resource recycling and environmental engineering, and can solve problems such as failure to meet the discharge standard of COD less than or equal to 50mg/L, consumption of large flocculants and coagulants, and difficulty in recovering oil and processing , to achieve the effect of reducing sludge treatment costs, saving chemical costs, and containing less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

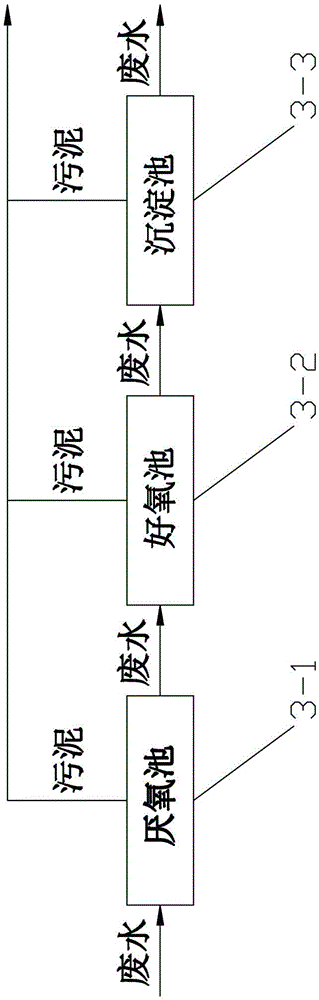

Method used

Image

Examples

Embodiment 1

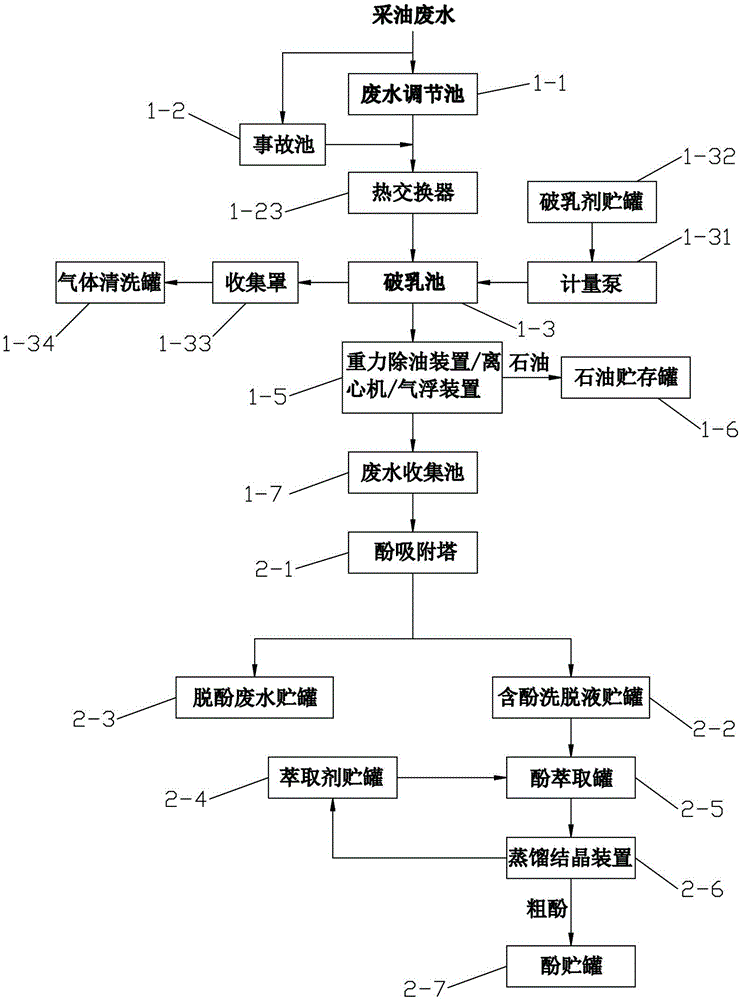

[0076] (1) Demulsification: Collect the oil production wastewater into the wastewater regulating tank 1-1 through the pipeline and mix it evenly in the wastewater regulating tank 1-1, adjust the water volume of the wastewater, and detect that its oil content is 50mg / L, COD is 300mg / L, The SS is 50mg / L, the salt content is 1000mg / L, and the pH is 6.5. Pump the oil production wastewater that has passed through the wastewater adjustment tank into the demulsification tank 1-3, add sulfuric acid to adjust the pH to 6 for demulsification, and press 5g / m 3 Join PAM.

[0077] (2) Oil recovery: pump the oil production waste water obtained from the demulsification in step (1) into the gravity deoiling device 1-5, and separate and recover the oil by gravity sedimentation to obtain 49g / m 3 And deoiled oil production wastewater, petroleum is stored in petroleum storage tanks 1-6, deoiled oil production wastewater is stored in wastewater collection pools 1-7, and the COD of wastewater drop...

Embodiment 2

[0090] (1) Demulsification: Collect the oil production waste water in the regulating pool 1-1 through the pipeline and mix it evenly in the regulating pool 1-1, adjust the water volume of the waste water, and detect that the oil content is 6000mg / L, the COD is 7000mg / L, and the SS is 500mg / L, salt content 20000mg / L, pH 9.5. Pump the oil production wastewater that has passed through the adjustment tank into the pH adjustment tank (demulsification tank) 1-3, add sulfuric acid to adjust the pH to 2 to break the emulsion, and press 10g / m 3 Join PAM.

[0091] (2) Oil recovery: the oil production wastewater obtained in step (1) demulsification is separated and recovered by a centrifuge to obtain 5998g / m of oil 3 And deoiling wastewater, oil is stored in storage tanks 1-6, deoiling wastewater is stored in wastewater collection pools 1-7, and the COD of wastewater drops from 7000mg / L to 892mg / L.

[0092] The centrifugal separation is to pump the demulsified oil production wastewater...

Embodiment 3

[0105] (1) Demulsification: Collect the oil production wastewater into the wastewater regulating tank 1-1 through the pipeline and mix it evenly in the wastewater regulating tank 1-1, adjust the water volume of the wastewater, and detect that its oil content is 450mg / L, COD is 610mg / L, The SS is 200mg / L, the salt content is 3200mg / L, and the pH is 7.2. Pump the oil production wastewater that has passed through the wastewater adjustment tank into the demulsification tank 1-3, add sulfuric acid to adjust the pH to 4 for demulsification, and press 4g / m 3 Join PAM.

[0106] (2) Oil recovery: pump the oil extraction waste water obtained from step (1) demulsification into the centrifuge 1-5 for separation, and recover 448g / m of oil 3 and oil production wastewater after deoiling, petroleum is stored in oil storage tanks 1-6, and oil production wastewater after deoiling is stored in wastewater collection pools 1-7.

[0107] The centrifugal separation is to pump the demulsified oil r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com