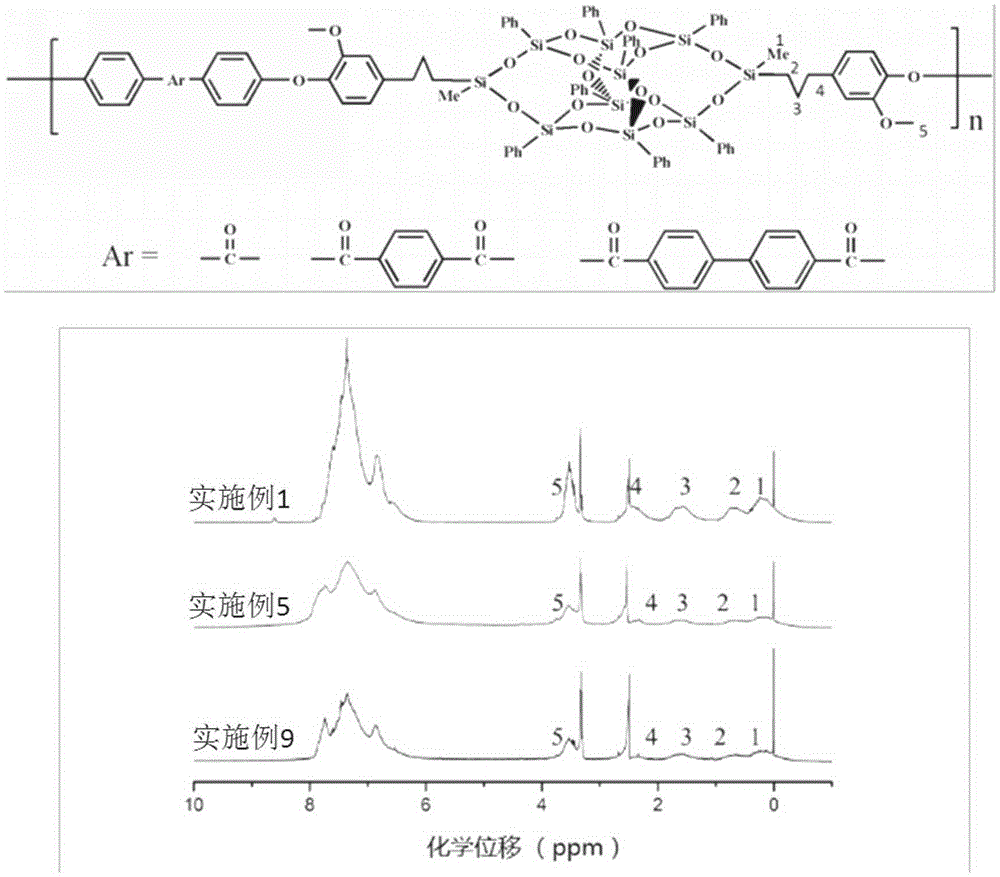

Poly(aryl ether ketone) resin with main chain containing polyhedral oligomeric silsesquioxane double-deck structure, and preparation method thereof

A technology of silsesquioxane and polyaryletherketone, which is applied in the field of low-dielectric hydrophobic polyaryletherketone resin and its preparation, can solve the problems of limited application, poor hydrophobicity and dielectric constant, etc., and achieve simple synthesis route, Excellent overall performance and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

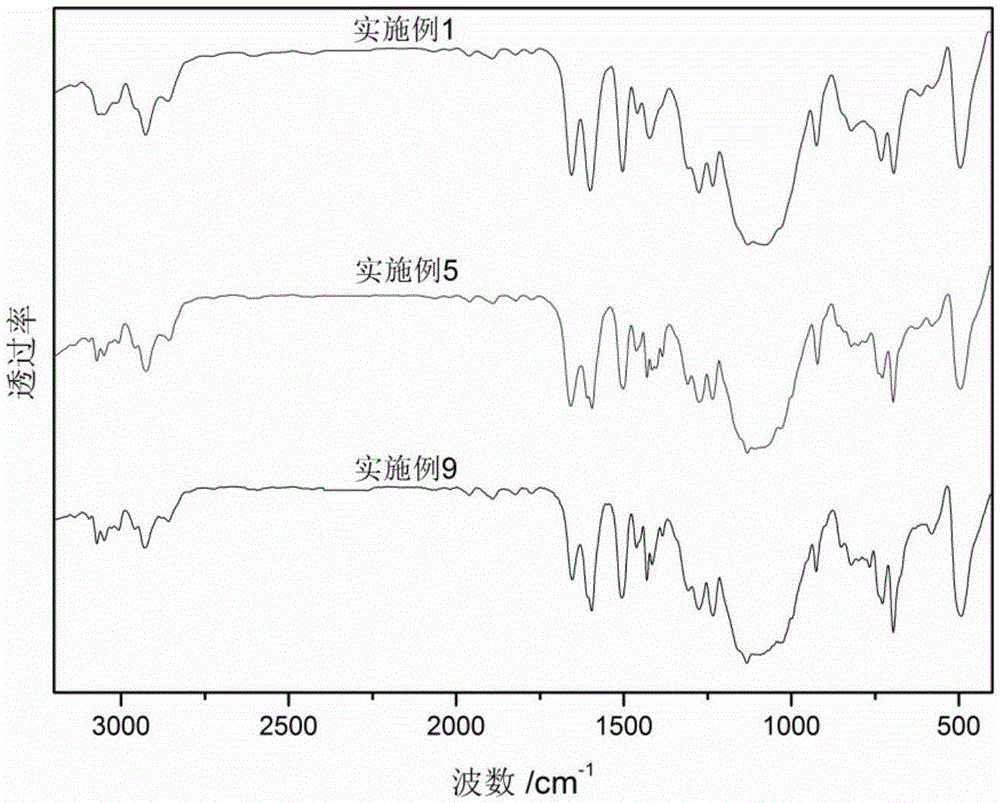

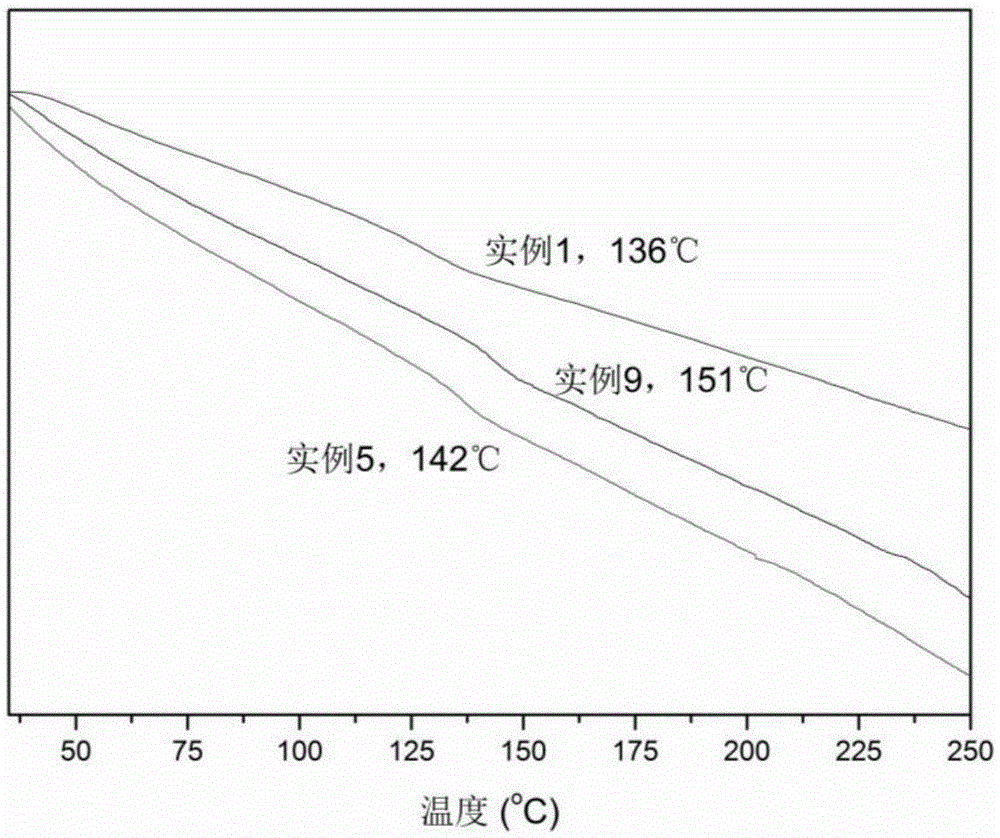

Embodiment 1

[0019] Under nitrogen protection, add 1.4822g (0.001mol) 2OH-DDSQ, 0.2182g (0.001mol) 4,4′-difluorobenzophenone and 0.166g (0.0012mol) potassium carbonate, 6.8mL sulfolane as solvent, and 3.4mL toluene as water-carrying agent. Raise the temperature to 140°C, and react with water to form a salt for 3 hours. Sequentially raise the temperature to 170°C, react at 190°C and 220°C for 2 hours each, and then precipitate out in deionized water. After pulverizing, wash 3 times with deionized water and methanol respectively, dry, then obtain the polyarylether ketone that main chain contains cage type silsesquioxane double plywood structure, product structural formula is shown in (1), and yield is 89.3%.

Embodiment 2

[0021] Under nitrogen protection, add 1.4822g (0.001mol) 2OH-DDSQ, 0.2182g (0.001mol) 4,4′-difluorobenzophenone and 0.166g (0.0012mol) potassium carbonate, 8.5mL sulfolane, and 4.3mL toluene are water-carrying agents. Raise the temperature to 140°C, and react with water to form a salt for 3 hours. Sequentially raise the temperature to 170°C, react at 190°C and 220°C for 2 hours each, and then precipitate out in deionized water. After pulverizing, wash 3 times with deionized water and methanol respectively, dry, then obtain the polyarylether ketone that main chain contains cage type silsesquioxane double plywood structure, product structural formula is shown in (1), and yield is 92.5%.

Embodiment 3

[0023] Under nitrogen protection, add 1.4822g (0.001mol) 2OH-DDSQ, 0.2182g (0.001mol) 4,4′-difluorobenzophenone and 0.138g (0.001mol) potassium carbonate, 8.5mL sulfolane, and 4.3mL toluene are water-carrying agents. Raise the temperature to 140°C, and react with water to form a salt for 3 hours. Sequentially raise the temperature to 170°C, react at 190°C and 220°C for 2 hours each, and then precipitate out in deionized water. After pulverizing, wash 3 times with deionized water and methanol respectively, dry, then obtain the polyarylether ketone that main chain contains cage type silsesquioxane double plywood structure, product structural formula is shown in (1), and yield is 87.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com