Environment-friendly and degradable excellent modified bamboo fiber

An environmentally friendly, bamboo fiber technology, applied in fiber processing, fiber mechanical separation, climate sustainability, etc., can solve the problems of long time, difficult to control, rough fermentation method, etc. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

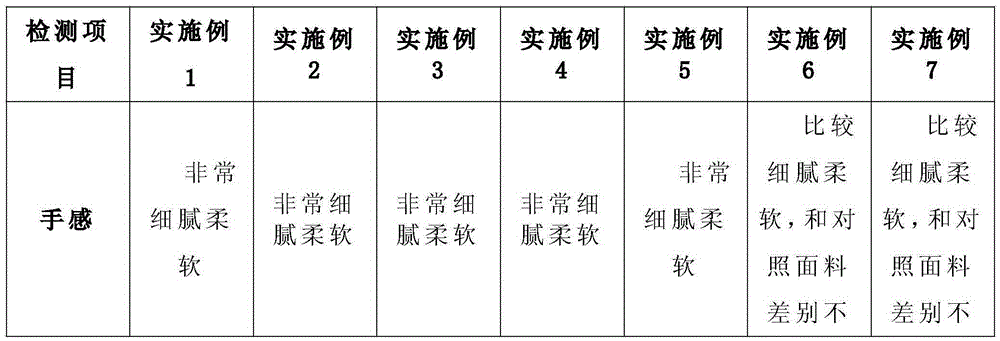

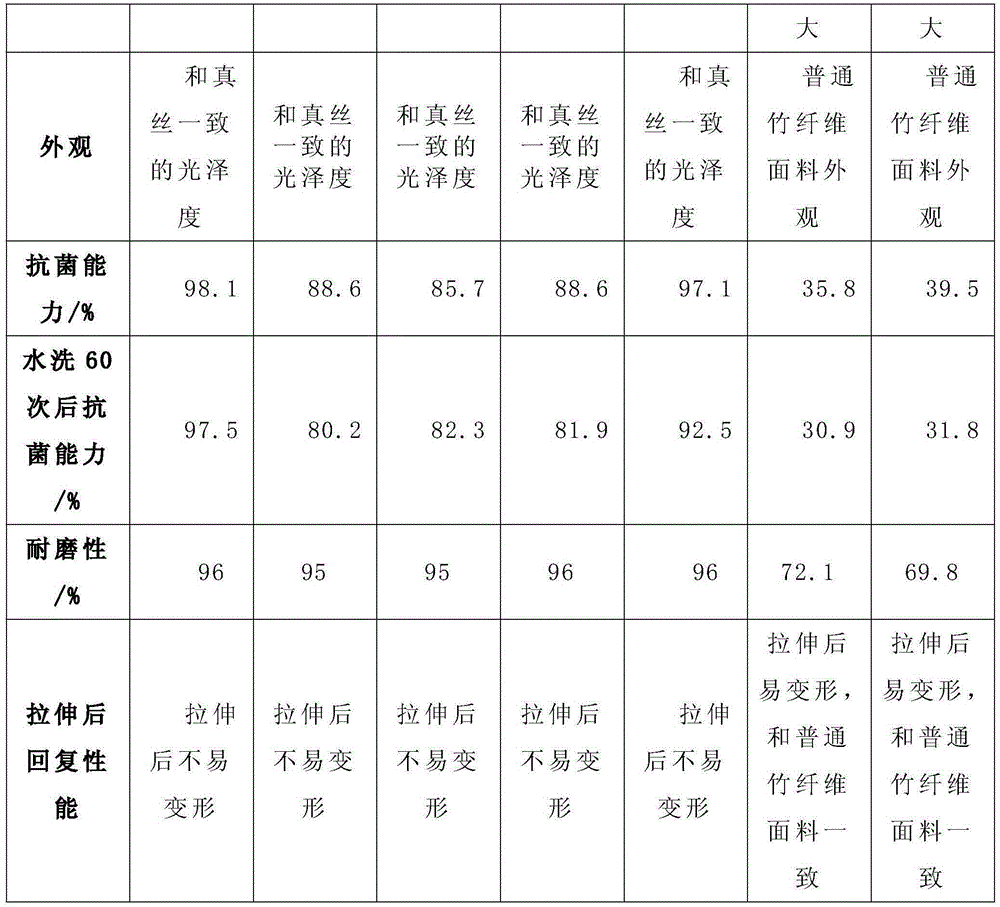

Examples

Embodiment 1

[0022] The bacterial agents used in the present invention are all purchased.

[0023] The preparation method of environmentally friendly and degradable excellent modified bamboo fiber, its preparation steps are as follows:

[0024] (1) Pretreatment: Take 1.5-year-old green bamboo, remove the tips, roots, bamboo joints, and greens, split the bamboo tube into bamboo slices with a width of 5 cm, put them in the boiling treatment solution and boil them for 20 minutes, then take them out, and then remove the bamboo slices. beat to loosen;

[0025] The formula of the boiled treatment solution is, according to the mass percentage, 2% tea saponin, 0.3% papain, 0.5% sodium chloride, and the rest is water;

[0026] (2) Biological fermentation treatment:

[0027] Bacillus subtilis, Sphingomonas, and Lactococcus lactis are formulated into a composite bacterial agent according to the quantitative ratio of 1:0.5:8;

[0028] The pretreated bamboo fiber is dropped into the nutrient solutio...

Embodiment 2

[0034] The preparation method of environmentally friendly and degradable excellent modified bamboo fiber, its preparation steps are as follows:

[0035] (1) Pretreatment: Take 1.5-year-old green bamboo, remove the tip, root, and bamboo joints, remove the green, split the bamboo tube into bamboo slices with a width of 5 cm, put it in the boiling treatment liquid and boil for 20-25min, then take it out, and remove the green bamboo. Beat the pieces to loosen them;

[0036] The formula of the boiled treatment liquid is, according to the mass percentage, tea saponin 2.3%, papain 0.2%, 0.5% sodium chloride, and the rest is water;

[0037] (2) Biological fermentation treatment:

[0038] Bacillus subtilis, Sphingomonas, and Lactococcus lactis are formulated into a composite bacterial agent according to the quantitative ratio of 1:0.5:8;

[0039] The pretreated bamboo fiber is dropped into the nutrient solution and submerged completely, and the formula of the nutrient solution is:

...

Embodiment 3

[0045] The preparation method of environmentally friendly and degradable excellent modified bamboo fiber, its preparation steps are as follows:

[0046] (1) Pretreatment: Get 2.5-year-old green bamboo, remove the tip, root, bamboo joints, and greens, split the bamboo tube into bamboo slices with a width of 5 cm, put them in the boiling treatment solution and boil them for 25 minutes. beat to loosen;

[0047] The formula of the boiled treatment liquid is, according to the mass percentage, tea saponin 2.1%, papain 0.2%, 0.5% sodium chloride, and the rest is water;

[0048] (2) Biological fermentation treatment:

[0049] Bacillus subtilis, Sphingomonas, and Lactococcus lactis are formulated into a composite bacterial agent according to the quantitative ratio of 1:0.5:8;

[0050] The pretreated bamboo fiber is dropped into the nutrient solution and submerged completely, and the formula of the nutrient solution is:

[0051] Corn syrup 1.2g / L, Vitamin B 2 : 20ug / L, vitamin C: 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com