Oxidized graphene/pure graphene/polyaniline ternary conductive composite material and preparation method thereof

A composite material, graphene technology, used in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of poor water solubility, oxygen-containing functional groups affecting conductivity, coagulation, etc., to achieve good conductivity, superior ratio Capacitance value, effect of high cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

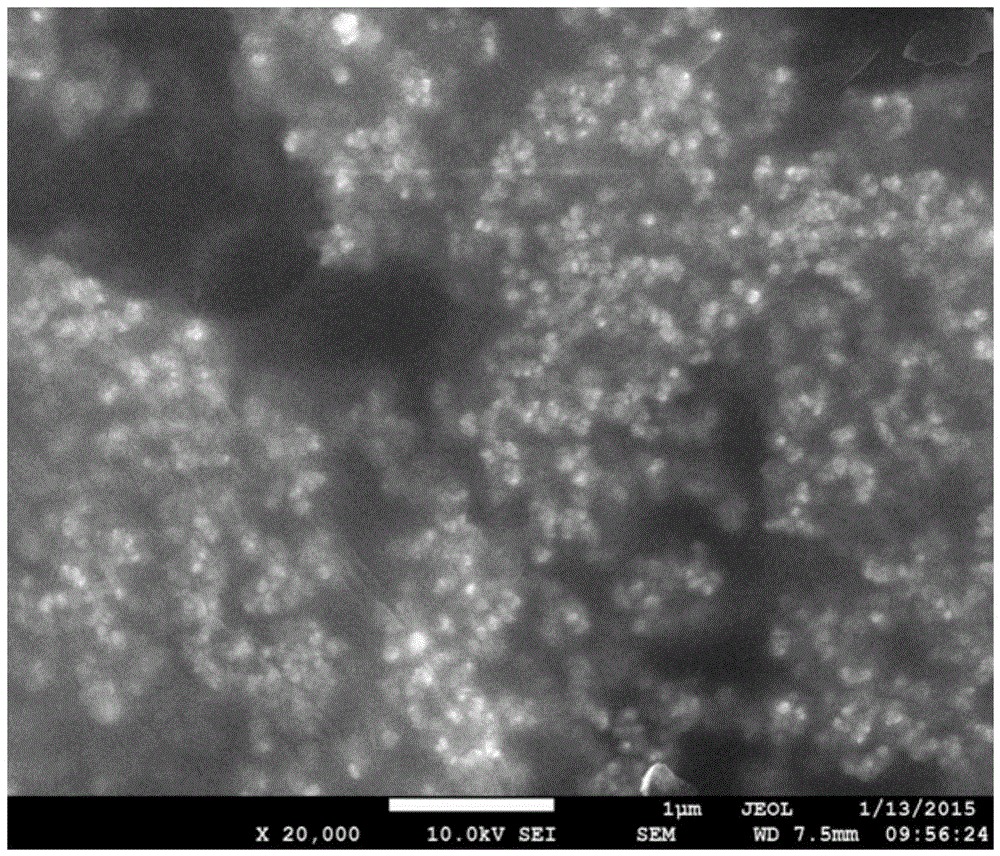

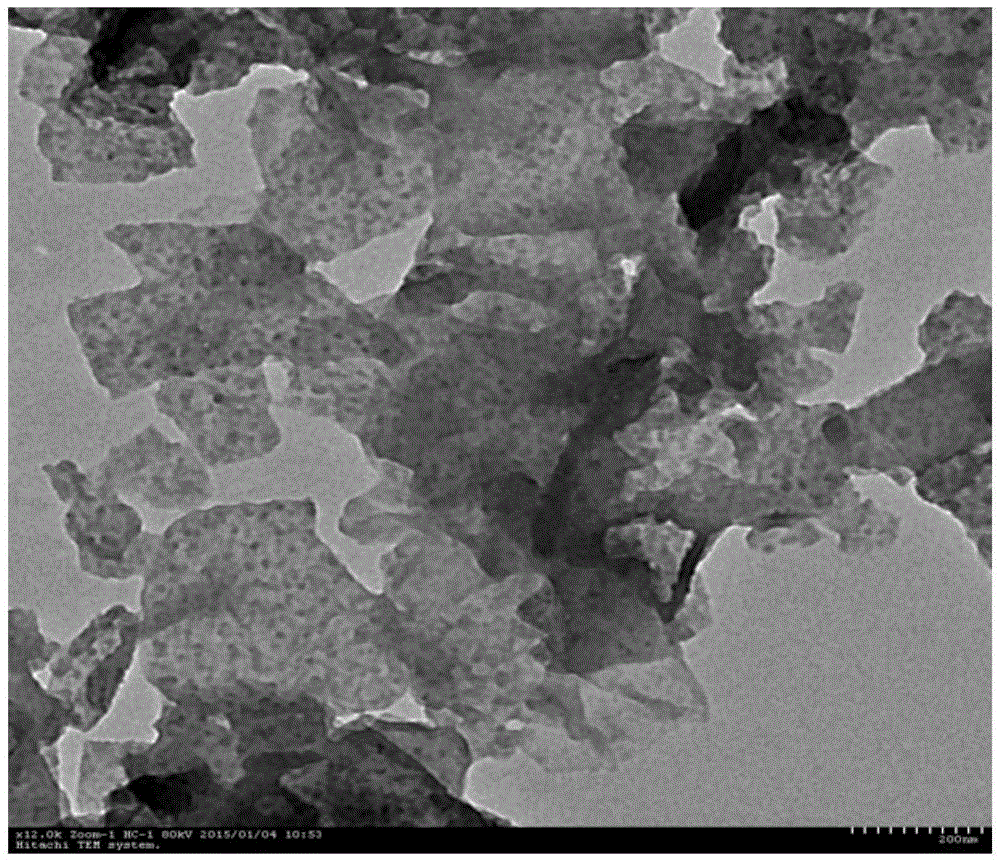

[0023] The preparation method of graphene oxide / pure graphene / polyaniline ternary composite material according to the present invention comprises the following steps: 1) preparation of graphene oxide / pure graphene composite: preparing pure graphite by liquid phase exfoliation Graphene oxide dispersion, adding graphite oxide into water to make a 0.5mg / mL solution and ultrasonically dispersing to obtain a graphene oxide dispersion; directly mixing the graphene oxide dispersion (water phase) and pure graphene dispersion (organic phase) and Ultrasonic for 30 minutes, ultrasonically dispersed after centrifugation and washing to obtain graphene oxide / pure graphene dispersion system; 2) Preparation of graphene oxide / pure graphene / polyaniline ternary composite material: the oxidation Add the aniline monomer solution containing HCl and the ammonium persulfate solution dispersed in water to the graphene / pure graphene composite solution, stir and react for more than 8 hours, vacuum filter...

Embodiment

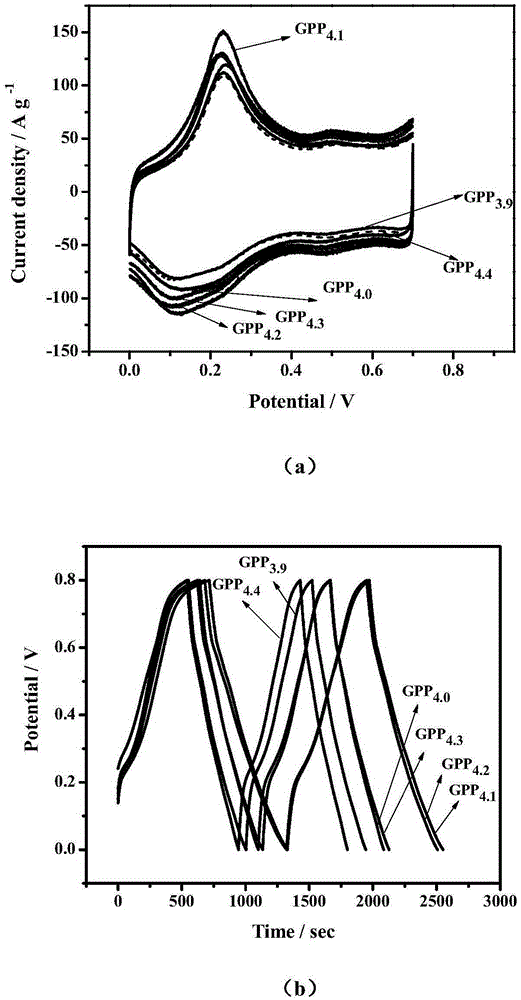

[0027] Add graphite oxide to water and ultrasonically disperse for 0.5-2h to form a uniform graphene oxide (GO) dispersion with a concentration of 0.5mg / mL, and use DMSO and trisodium citrate to obtain pure graphene (PG) dispersion , the concentration is 0.5mg / mL; take a certain amount of PG / DMSO dispersion and GO / H2O dispersion and mix them directly, wherein the mass ratio of PG to GO is 2:3, after ultrasonication for 30min, vacuum filter and wash directly in water Ultrasonic dispersion (or disperse the GO / PG composite into water by centrifugation); add the aniline monomer solution containing HCl and the ammonium persulfate solution dispersed in water to the GO / PG composite solution and stir for 8 hours , wherein the mass ratio of GO / PG composite to aniline is 1 / 4.1, and ultrasonically dispersed after vacuum filtration and washing to obtain a ternary composite of GO / PG / PANI; the prepared coating liquid is dropped onto a polished glass The carbon electrode and the cleaned FTO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com