Single-mode vertical cavity surface emitting laser transceiver module and optical signal propagation method

A vertical cavity surface emission, transceiver module technology, applied in the field of optical interconnection, can solve the problem of not considering polarization sensitivity, and achieve the requirements of reducing alignment accuracy, improving interconnection bandwidth and interconnection density, and easy coupling and alignment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

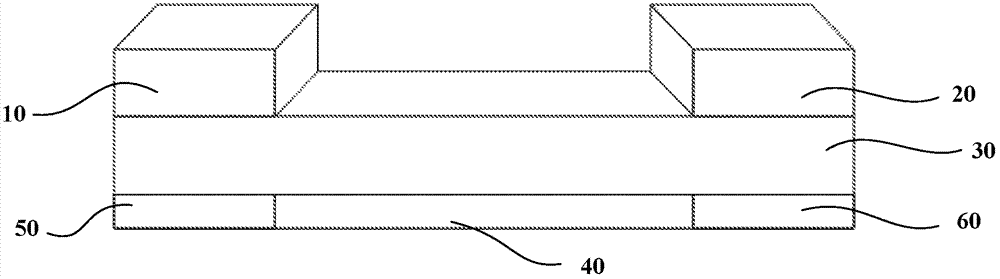

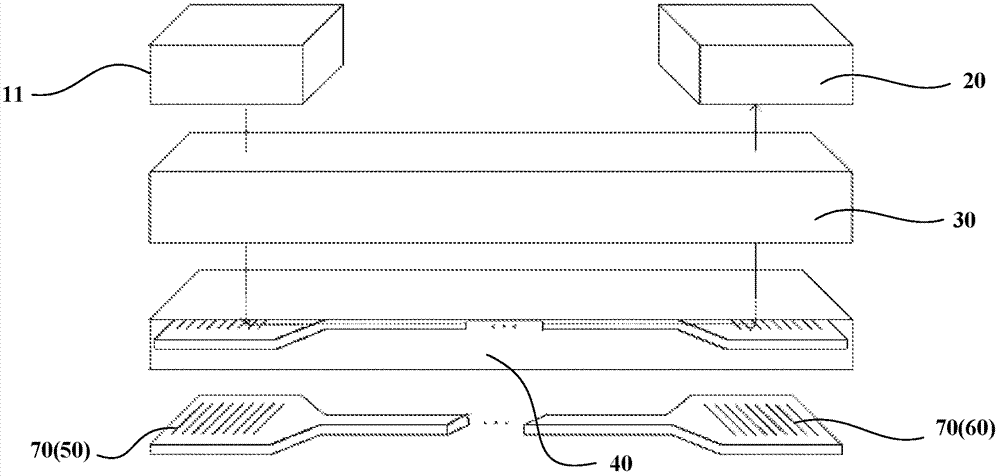

[0057] like image 3 As shown, the single-mode photonic crystal VCSEL is a single-polarized single-mode photonic crystal VCSEL11, and the vertical grating coupler is a one-dimensional single-polarization vertical grating coupler 70, that is, the first vertical grating coupler 50 and the second vertical grating coupler 60 are both is a one-dimensional single-polarization vertical grating coupler 70, and the coupling angle of the one-dimensional single-polarization vertical grating coupler 70 is 90°, and the light polarization mode of the one-dimensional single-polarization vertical grating coupler is the same as that of a single-polarized single-mode photonic crystal The light polarization modes of the VCSEL 11 are matched.

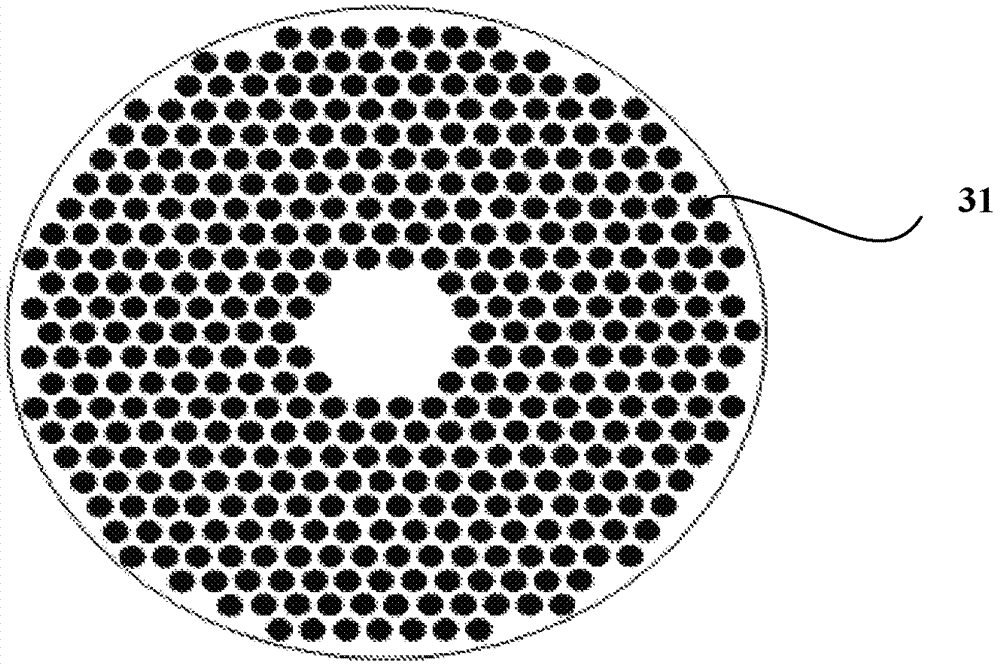

[0058] reference together Figure 4 and Figure 5 , Figure 4 shows the structure of a single-polarized single-mode photonic crystal VCSEL, Figure 5 The end face structure of the two-dimensional photonic crystal VCSEL is shown; wherein, the single-pol...

Embodiment 2

[0065] like Figure 8 As shown, the single-mode photonic crystal VCSEL is a single-mode photonic crystal VCSEL 12 in a non-polarized mode, the vertical grating coupler is a two-dimensional vertical grating coupler 80, and the coupling angle of the two-dimensional vertical grating coupler 80 is 90°, that is, the first Both the one vertical grating coupler 50 and the second vertical grating coupler 60 are two-dimensional vertical grating couplers 80 .

[0066] The non-polarized mode single-mode photonic crystal VCSEL 12 includes: an n-type ohmic contact layer, a substrate, an underlying distributed Bragg mirror DBR, an active layer, an oxide layer arranged in sequence along the direction away from the n-type ohmic contact layer and a top layer DBR; wherein, the top layer DBR is etched with a two-dimensional photonic crystal VCSEL and a p-type ohmic contact layer, and the etched two-dimensional photonic crystal VCSEL includes a plurality of circular holes. The two-dimensional ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com