Early-strength waterproof agent for ordinary Portland cement

A common portland cement and waterproofing agent technology, applied in the field of early-strength waterproofing agent, can solve problems such as harm or impact on the human body and the environment, achieve excellent waterproof performance, and promote the effect of early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

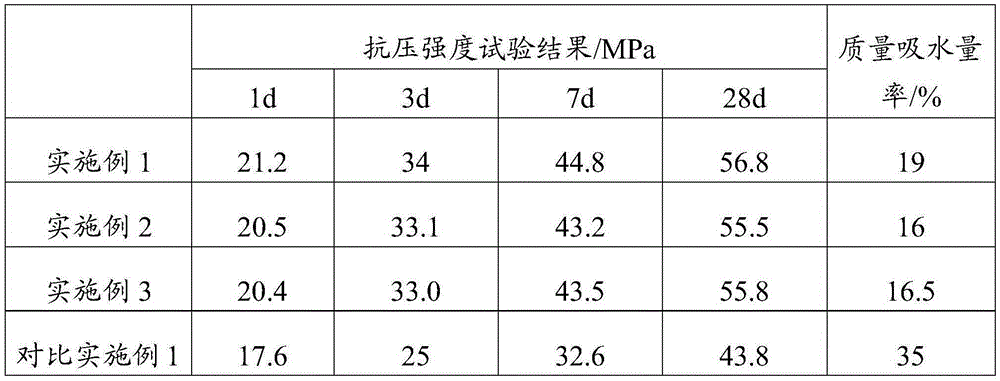

Examples

Embodiment 1

[0014] Take g as the unit, weigh the following component raw materials: calcium sulfate 200g, sodium tripolyphosphate 7g, sodium hydroxide 200g, stearic acid 7g, fatty acid potassium 0.7g, nut oil 0.4g, linolenic acid 0.2g, particle size is 250 Objective 0.4g of hydrogenated rosin, 0.3g of gelatin, 15g of diatomite with a particle size of 200, and 0.01g of rutin are mixed and stirred evenly to obtain an early-strength waterproofing agent for ordinary Portland cement, which is ready for use.

[0015] Weigh 200g of ordinary Portland cement, 50g of quartz sand, soak the quartz sand in alkaline water with a mass concentration of 50% for 5h before use, 5g of fly ash, 10g of naphthalenesulfonate formaldehyde condensate superplasticizer, diameter It is 50g of crushed stones of 10-15mm, and 4g of the above-mentioned prepared early-strength waterproofing agent is used for ordinary Portland cement. Put the obtained ordinary Portland cement, quartz sand, fly ash, naphthalene sulfonate fo...

Embodiment 2

[0019] Take g as the unit, weigh the following component raw materials: calcium sulfate 100g, sodium tripolyphosphate 5g, sodium hydroxide 100g, stearic acid 5g, fatty acid potassium 0.5g, nut oil 0.2g, linolenic acid 0.1g, particle size is 150 Objective 0.2g of hydrogenated rosin, 0.2g of glue and 10g of diatomaceous earth with a particle size of 200 are mixed and stirred evenly to obtain an early-strength waterproofing agent for ordinary portland cement, which is ready for use.

[0020] Weigh 200g of ordinary Portland cement, 50g of quartz sand, soak the quartz sand in alkaline water with a mass concentration of 50% for 6h before use, 5g of fly ash, 10g of naphthalenesulfonate formaldehyde condensate superplasticizer, diameter It is 50g of crushed stones of 10-15mm, and 2g of the above-mentioned prepared early-strength waterproofing agent is used for ordinary Portland cement. Put the ordinary Portland cement, quartz sand, fly ash, naphthalene sulfonate formaldehyde condensat...

Embodiment 3

[0024] Take g as the unit, weigh the following component raw materials: calcium sulfate 300g, sodium tripolyphosphate 10g, sodium hydroxide 300g, stearic acid 10g, fatty acid potassium 1g, nut oil 0.5g, linolenic acid 0.3g, particle size is 200 mesh 0.6g of hydrogenated rosin, 0.4g of animal glue and 20g of diatomite with a particle size of 200 are mixed and stirred evenly to obtain an early-strength waterproofing agent for ordinary Portland cement, which is ready for use.

[0025] Weigh 200g of ordinary Portland cement, 50g of quartz sand, soak the quartz sand in alkaline water with a mass concentration of 50% for 5h before use, 5g of fly ash, 10g of naphthalenesulfonate formaldehyde condensate superplasticizer, diameter It is 50g of crushed stones of 10-15mm, and 6g of the above-mentioned prepared early-strength waterproofing agent is used for ordinary Portland cement. Put the obtained ordinary Portland cement, quartz sand, fly ash, naphthalene sulfonate formaldehyde condens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com