Medium formula improving water holding capacity and air permeability of golden mushroom medium

A culture medium formulation and culture medium technology, which is applied to fertilizers, organic fertilizers, and fertilizer mixtures made of biological waste, can solve the problems of poor water retention capacity, low water content of Flammulina velutipes culture medium, and poor medium permeability, and achieves Strong permeability, rich source of raw materials, and significant effects of increasing production and income

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The present invention also provides a preparation method of a culture medium formula for improving water holding capacity and air permeability of Flammulina velutipes culture medium, comprising the steps of:

[0047] Step 1: Prepare medium raw materials respectively according to parts by weight:

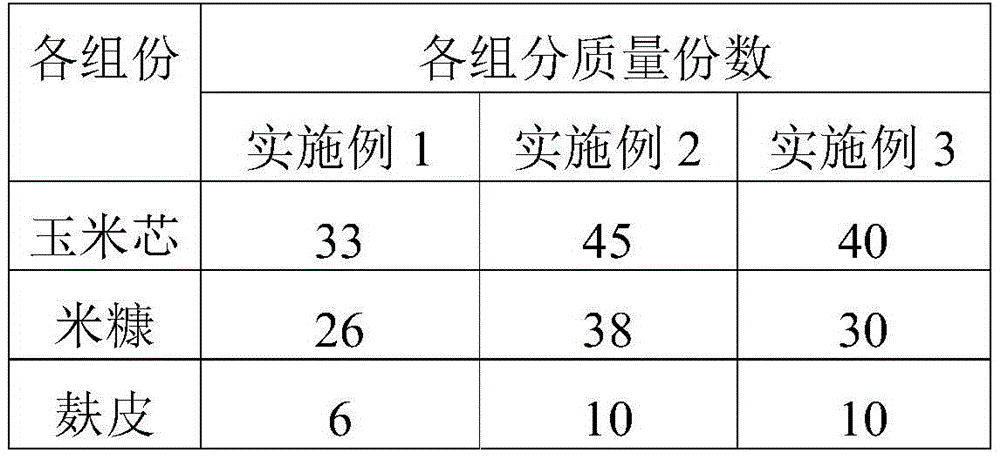

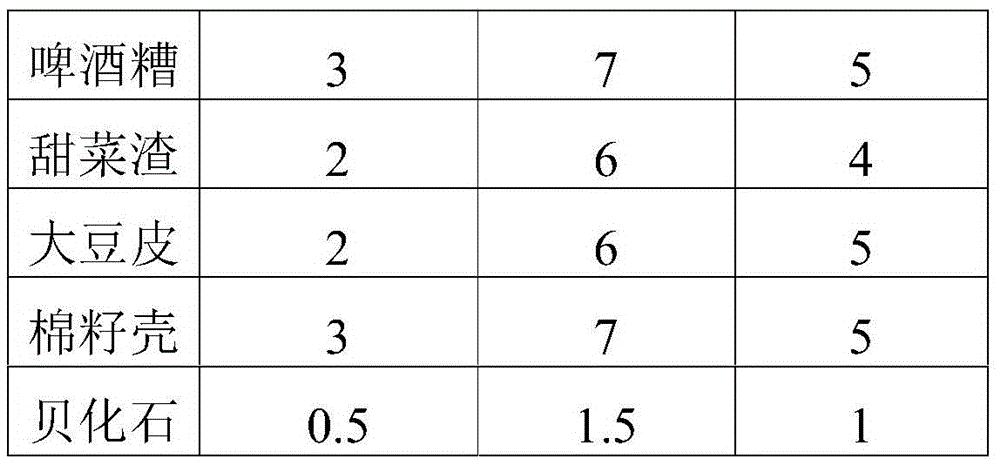

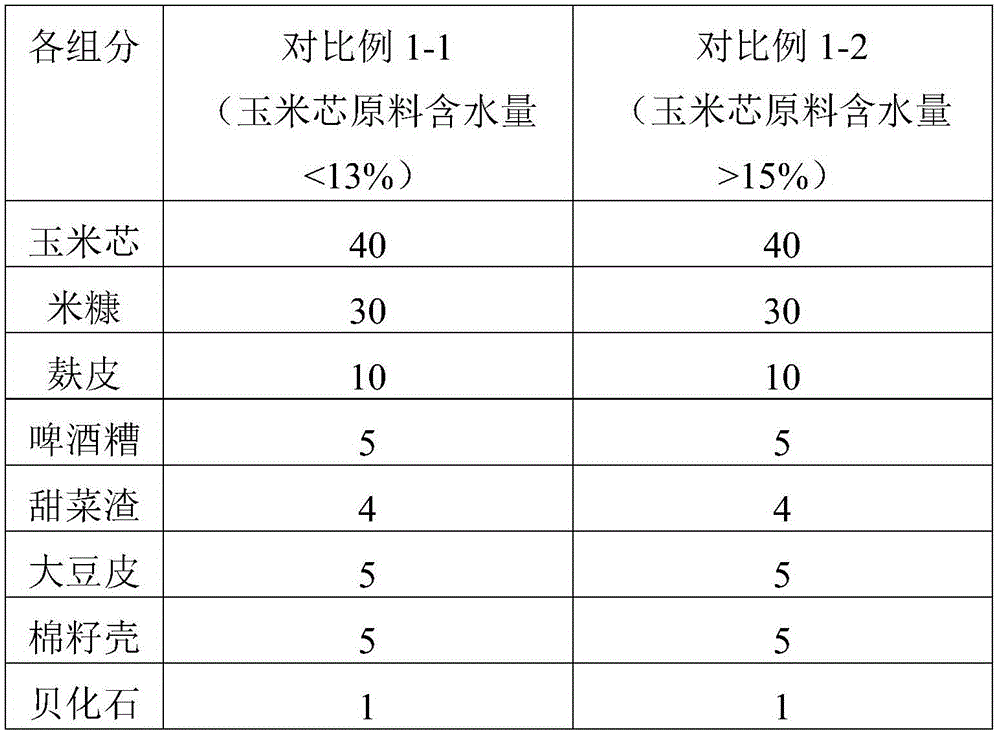

[0048] 33-45 parts of corn cob, 26-38 parts of rice bran, 6-10 parts of bran, 3-7 parts of cottonseed hull, 0.5-1.5 parts of shell fossil, 2-6 parts of soybean hulls, 3-7 parts of brewer's grains, sugar beet residue 2 to 6 copies;

[0049] Step 2: Put these raw materials into the mixing pot in order of corn cob, rice bran, bran, brewer's grains, beet residue, soybean hulls, cottonseed shells, shell fossils, etc. After adding water, the water content of the medium is controlled at 68% to 72%, and the medium is stirred evenly;

[0050] Step 3: Use a fully automatic bottling machine, which requires uniform bottling and moderate compactness;

[0051] Wherein, in step 2, put the...

Embodiment

[0061] 1. Raw material mixing

[0062] Preparation of medium formulations for improving water holding capacity and air permeability of Flammulina velutipes culture medium: Prepare raw materials respectively according to each component in Table 1 and the mass fraction of each component. Put skins, brewer's grains, sugar beet dregs, soybean hulls, cottonseed hulls, shell fossils, etc. into the stirring pot in sequence, dry stirring for 25 minutes, and then slowly add water at 15-25°C, the speed of adding water should not exceed 150 liters per minute, add water When the water content is 68% to 72%, stir for another 70 minutes and stir evenly;

[0063] Among them, the requirements for beet pulp are: to process the beet pulp. The processing method is that the beet is peeled off the skin and whiskers, and then turned into beet granules after sugar extraction. The water absorption of the beet granules is required to be greater than 500%. white beet core, the particles after soaking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com