A kind of halophilic desulfurization bacterial strain and its application

A bacterial strain and hydrogen sulfide technology, applied in the field of microorganisms, can solve the problems of poor stability of the biological desulfurization system, low osmotic pressure resistance, and influence on industrial applications, so as to reduce the operating cost of biological desulfurization, high osmotic pressure resistance, and less waste water The effect of discharge and consumption of lye

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

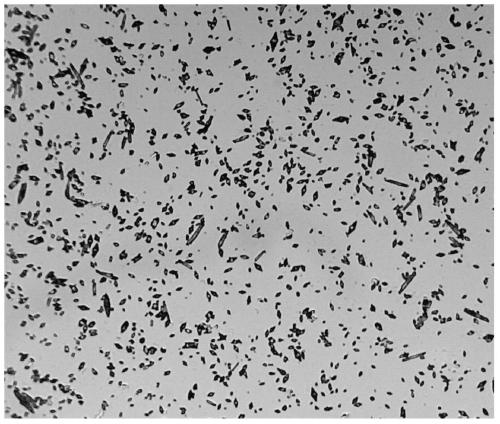

[0046] Experiment on halophilicity of desulfurization strain NPE-1

[0047] 1. Feed CO into NaOH solutions with different concentrations of 2%, 3%, 4%, 5%, 6%, and 7% respectively 2 , so that the pH of each NaOH solution is between 8.5-9.0, and about 4%, 6%, 8%, 10%, 12%, 14% Na 2 CO 3 and NaHCO 3 mixed solution.

[0048] 2. Add NaHS solution with a pH of 8.5-9.0 to different concentrations of NaHS 2 CO 3 and NaHCO 3 In the mixed solution, the final concentration of NaHS was kept at about 1%.

[0049] 3. To different Na 2 CO 3 and NaHCO 3 Inject the same amount of NPE-1 strains into the mixed solution of the same concentration, and place it in a shaker at 37°C for shaking culture.

[0050] 4. Observe the growth of NPE-1 strain at each concentration every 8 hours.

[0051] After testing, it was found that NPE-1 in 14% Na 2 CO 3 and NaHCO 3 In the mixed solution, the growth is slow, the number of bacteria does not increase, and the Na content below 10% 2 CO 3 and...

Embodiment 2

[0053] Desulfurization Effect Test of Desulfurization Bacteria Strain NPE-1

[0054] 1. Air source composition: H 2 S concentration 0.4%, CO 2 Concentration 45%, N 2 Concentration 54%;

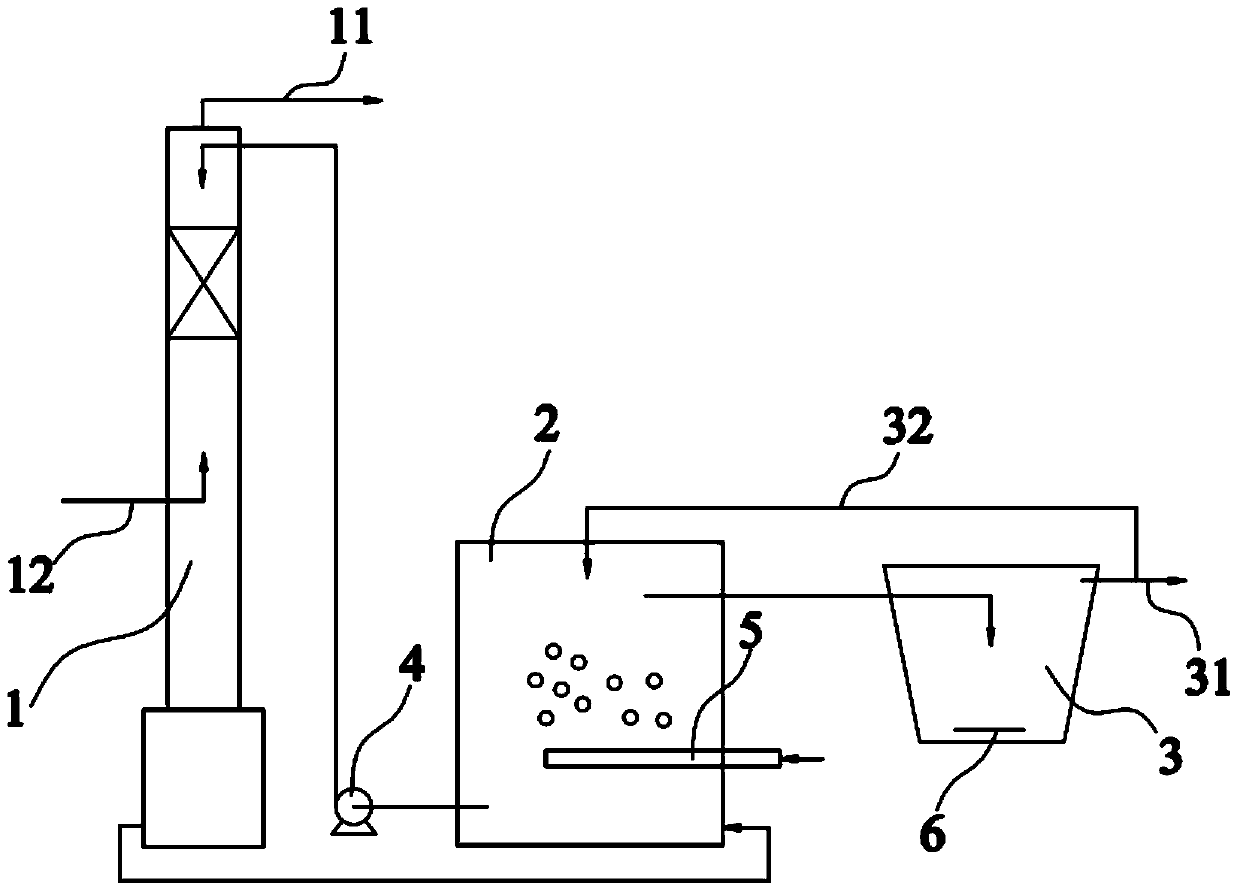

[0055] 2. Test equipment: adopt figure 1 The device shown is a self-made scrubber, cylindrical, with a ground diameter of 10cm and a height of 1200cm; a self-made biological regeneration reactor, which belongs to an upflow aerobic reactor, with an effective volume of 42L, a bottom diameter of 25cm, and a total height of 100cm; elemental sulfur separator Self-made, conical, effective volume 5L, total height 60cm;

[0056] 3. Culture conditions: 37°C, pH8.5-9.0, ORP (Oxidation-Reduction Potential, oxidation-reduction potential) controlled between -320mv and -400mv;

[0057] 4. Washing liquid composition: 7%-10% Na 2 CO 3 and NaHCO 3 mixture;

[0058] After the whole system is stable, by analyzing the H in the gas entering and leaving the system 2 S concentration, the calculated NPE-1 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com