Method for measuring content of aluminum powder in titanium tetrachloride suspension liquid

A technology of titanium tetrachloride and suspension, applied in the field of chemical analysis, to achieve good precision and recovery, and strong practical application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

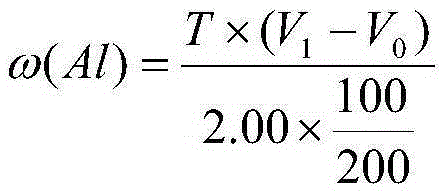

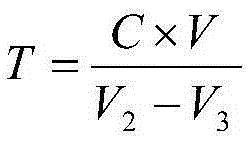

Method used

Image

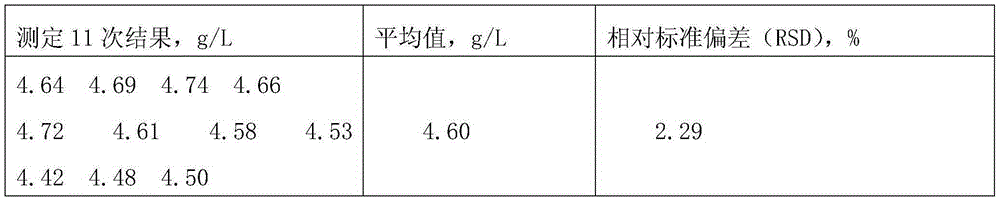

Examples

Embodiment 1

[0052] Example 1 Copper Standard Solution Back Titration Determination of Aluminum Powder Content in the Thick Titanium Tetrachloride Suspension

[0053] a. Use a dry plastic graduated straw to accurately pipette 2.00mL of 1# suspension into a 100mL centrifuge tube filled with 50mL of ethanol, shake well, and filter it into a beaker with fast filter paper. Before filtering, filter the filter paper, funnel and beaker with ethanol respectively. After the solution is wetted and filtered dry, wash the centrifuge tube and precipitate with ethanol for 8-10 times;

[0054] b. Heat and dissolve the precipitate with 10mL hydrochloric acid (1+1), add 10mL nitric acid and 5mL perchloric acid, evaporate to dryness with perchloric acid fumes, remove and cool, add 10mL hydrochloric acid (1+1) and heat to dissolve, add water to 100mL ;

[0055] c. Add 2-3mL ferric chloride solution (100g / L), boil it down, adjust it with sodium hydroxide solution (400g / L) until the precipitation of ferric hy...

Embodiment 2

[0076] Example 2 Zinc Standard Solution Back Titration Determination of Aluminum Powder Content in the Thick Titanium Tetrachloride Suspension

[0077] a. Use a dry glass graduated dropper to accurately pipette 2.50mL of 1# suspension into a 100mL ordinary test tube filled with 60mL of ethanol, shake well, and filter it into a beaker with a fast filter paper. Before filtering, use the filter paper, funnel and beaker respectively Wet with ethanol solution, filter and dry, wash the test tube with ethanol and precipitate 8-10 times;

[0078] b. Heat and dissolve the precipitate with 10mL hydrochloric acid (1+1), add 10mL nitric acid and 5mL perchloric acid, evaporate to dryness with perchloric acid fumes, remove and cool, add 10mL hydrochloric acid (1+1) and heat to dissolve, add water to 100mL ;

[0079] c. Add 2-3mL ferric chloride solution (100g / L), boil it down, adjust it with sodium hydroxide solution (400g / L) until the precipitation of ferric hydroxide just appears (at thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com