Superconducting composite adhesive electrode paste, preparation method of superconducting composite adhesive electrode paste and preparation method of electrode slice of sulfur anode of superconducting lithium-sulfur battery

A technology of electrode slurry and lithium-sulfur battery, which is applied in electrode manufacturing, battery electrodes, secondary batteries, etc. It can solve the problems of health threats to workers, high toxicity, and serious environmental pollution, and achieve the effect of improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

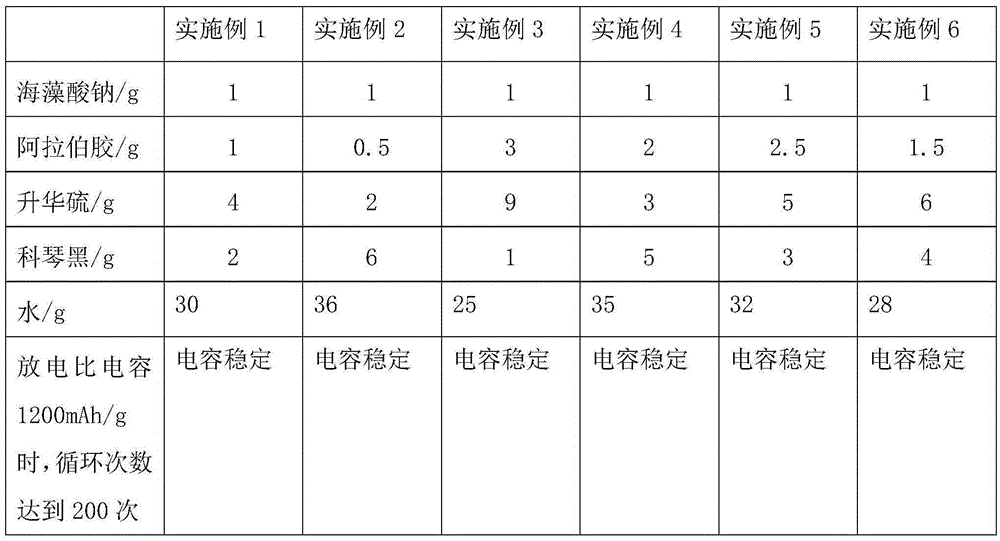

[0023] A superconducting composite gel electrode slurry, the components and contents are shown in Table 1.

[0024] The preparation method is as follows: uniformly mix sodium alginate with gum arabic according to the formula ratio, add water to dissolve and disperse, add elemental sulfur and ketjen black, and stir until uniformly mixed.

[0025] Further preparing it into a sulfur positive electrode sheet for a superconducting lithium-sulfur battery comprises the following steps:

[0026] 1) Wash the aluminum foil with deionized water and acetone in turn, dry it, and cut it into discs with a diameter of 14mm;

[0027] 2) Pour 10-12uL of the above-mentioned slurry on the cleaned and dried aluminum foil, use a scraper with a thickness of 200-400μm to evenly coat the slurry on the rough surface of the aluminum foil, and first vacuum dry at 60°C, The drying time is 8 hours, and the drying temperature at normal pressure is 80° C., and the drying time is 2 hours, so that the positiv...

Embodiment 2

[0030] A superconducting composite gel electrode slurry, the components and contents are shown in Table 1.

[0031] Its preparation method is with embodiment 1.

[0032] The method for making the electrode sheet is the same as in Example 1.

[0033] See Table 1 for the performance test results of the lithium-sulfur battery using the electrode sheets of this implementation.

Embodiment 3

[0035] A superconducting composite gel electrode slurry, the components and contents are shown in Table 1.

[0036] Its preparation method is with embodiment 1.

[0037] The method for making the electrode sheet is the same as in Example 1.

[0038] See Table 1 for the performance test results of the lithium-sulfur battery using the electrode sheets of this implementation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com