Cultivation method for lentinula edodes

A cultivation method and technology of shiitake mushrooms, which are applied in mushroom cultivation, cultivation, plant cultivation, etc., can solve the problems of affecting the growth of shiitake mushroom hyphae, easy mold contamination of sawdust, and low productivity of shiitake mushrooms, so as to inhibit the growth of miscellaneous bacteria and provide biological The effect of learning efficiency and increasing the yield of shiitake mushrooms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

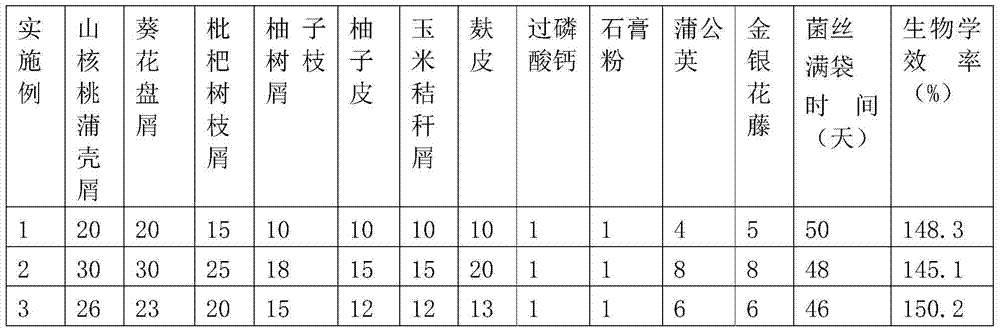

Embodiment 1

[0023] A cultivation method of shiitake mushrooms, comprising the following steps:

[0024] (1) Making cultivation material

[0025] The cultivation material formula is: 20 parts of hickory cattail crumbs, 20 parts of sunflower disc crumbs, 15 parts of loquat twig chips, 10 parts of grapefruit twig chips, 10 parts of grapefruit peel, 10 parts of corn stalk chips, 10 parts of bran, superphosphate 1 part, 1 part of gypsum powder, 4 parts of dandelion, 5 parts of honeysuckle vine; said substances are parts by weight of dry matter;

[0026] Pecan husk scraps are obtained after harvested hickory nuts are mechanically stripped off the cattail husks; 1. Corn stalks are dried in the sun and crushed;

[0027] Make planting material according to above-mentioned formula:

[0028] 1. Weigh grapefruit peel, dandelion, and honeysuckle vine respectively according to the above parts by weight, crush to 50-100 mesh, and set aside;

[0029] ② Weigh the hickory cattail husk, sunflower disc, ...

Embodiment 2

[0036] A cultivation method of shiitake mushrooms, comprising the following steps:

[0037] (1) Making cultivation material

[0038] The cultivation material formula is: 30 parts of hickory cattail crumbs, 30 parts of sunflower disc crumbs, 25 parts of loquat twig chips, 18 parts of grapefruit twig chips, 15 parts of grapefruit peel, 15 parts of corn stalk chips, 20 parts of bran, superphosphate 1 part, 1 part of gypsum powder, 8 parts of dandelion, 8 parts of honeysuckle vine; said substances are parts by weight of dry matter;

[0039] Production Method:

[0040] 1. Weigh grapefruit peel, dandelion, and honeysuckle vine respectively according to the above parts by weight, crush to 50-100 mesh, and set aside;

[0041] ② Weigh the hickory cattail husk, sunflower disc, loquat twig, grapefruit twig, corn stalk shavings according to the above parts by weight, mix well, add water and stir;

[0042] ③Mix the substances in step ① and step ② with bran, superphosphate, and gypsum po...

Embodiment 3

[0048] A cultivation method of shiitake mushrooms, comprising the following steps:

[0049] (1) Making cultivation material

[0050] The cultivation material formula is: 26 parts of hickory cattail husks, 23 parts of sunflower discs, 20 parts of loquat twigs, 15 parts of grapefruit twigs, 12 parts of grapefruit peels, 12 parts of corn stalks, 13 parts of bran, superphosphate 1 part, 1 part of gypsum powder, 6 parts of dandelion, 6 parts of honeysuckle vine; said substances are parts by weight of dry matter;

[0051] Production Method:

[0052] 1. Weigh grapefruit peel, dandelion, and honeysuckle vine respectively according to the above parts by weight, crush to 50-100 mesh, and set aside;

[0053] ② Weigh the hickory cattail husk, sunflower disc, loquat twig, grapefruit twig, corn stalk shavings according to the above parts by weight, mix well, add water and stir;

[0054] ③Mix the substances in step ① and step ② with bran, superphosphate, and gypsum powder, and place them ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com