Low-melting-point compound suspension and preparation method thereof

A compound, low melting point technology, applied in the field of pesticides, can solve the problems of high energy consumption, short development history, flocculation, etc., and achieve the effects of simple equipment selection, simple processing technology, and wide application area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: Preparation of pyraclostrobin suspension concentrate

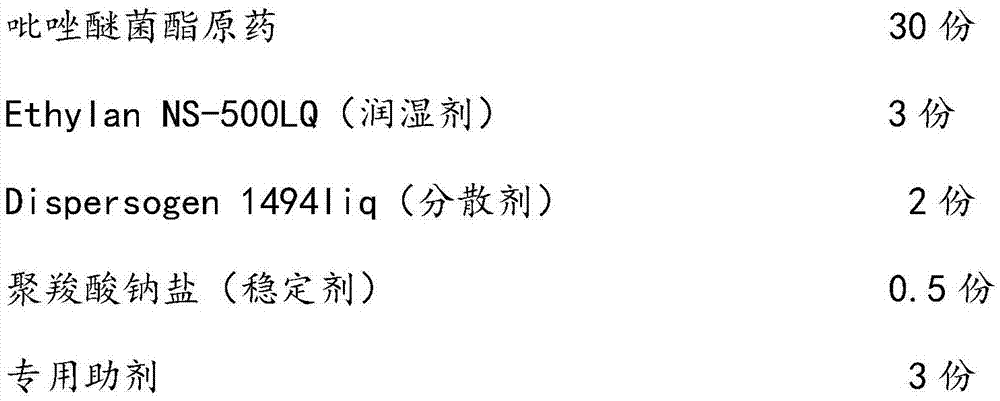

[0022] The content of each component is as follows:

[0023]

[0024]

[0025] Preparation method: first prepare special additives, weigh 8 parts of isooctyl alcohol polyoxyethylene ether, 9 parts of calcium dodecylbenzenesulfonate, 8 parts of diisooctyl sodium sulfosuccinate, 10 parts of secondary octanol and 3 parts of liquid paraffin, placed in a homogenizer, stirred and mixed until uniform, to obtain.

[0026] Add proportionally weighed EthylanNS-500LQ, Dispersogen1494liq, polycarboxylate sodium salt, special additives, ethylene glycol, sodium benzoate, Sag*1522 and water into the stirring tank, stir evenly to obtain the mixed solution A, and then add the mixed solution Add the pyraclostrobin technical substance to A, and stir continuously during the addition process, so that the pyraclostrobin technical substance is completely soaked into the mixture A, and then stir for 30 minutes. Put th...

Embodiment 2

[0027] Embodiment 2: preparation myclobutanil suspension concentrate

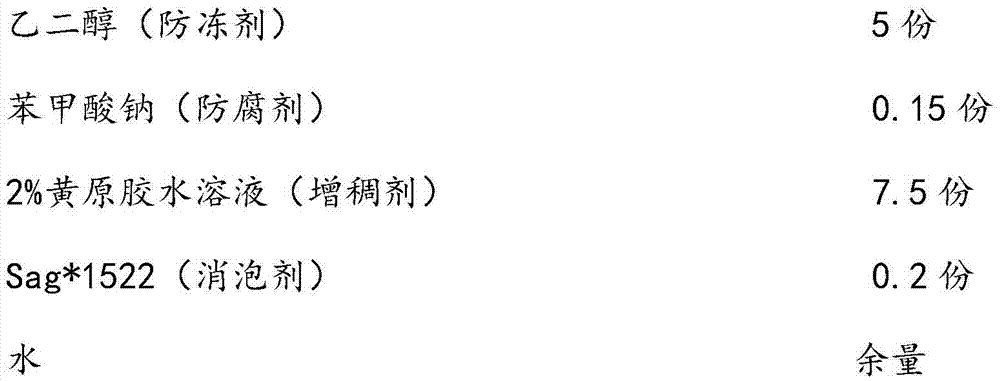

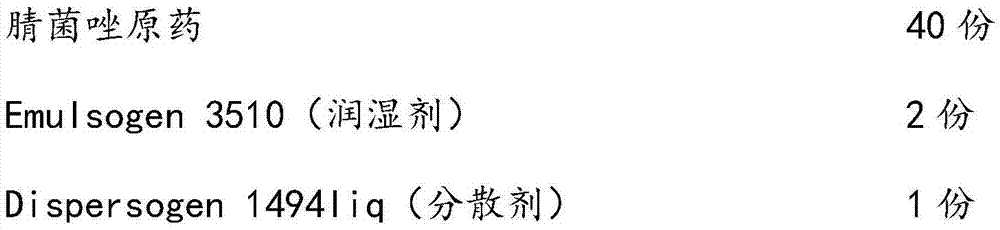

[0028] The content of each component is as follows:

[0029]

[0030]

[0031] Preparation method: first prepare special additives, weigh 13 parts of isooctyl alcohol polyoxyethylene ether, 15 parts of calcium dodecylbenzenesulfonate, 14 parts of diisooctyl sodium sulfosuccinate, 12 parts of sec-octanol and 4 parts of liquid paraffin, placed in a homomixer and stirred until uniform, to obtain.

[0032] Add Emulsogen3510, Dispersogen1494liq, EmulsonAGTRN14105, special additives, ethylene glycol, Cathone, magnesium aluminum silicate, Sag*1572 and water weighed in proportion to the stirring tank, stir evenly to obtain mixed solution A, and then add mixed solution A Add the original drug of myclobutanil to the mixture, and stir continuously during the adding process, so that the original drug of myclobutanil is completely soaked into the mixed solution A, and then stir for another 30 minutes. Put the mi...

Embodiment 3

[0033] Embodiment 3: preparation pendimethalin suspension

[0034] The content of each component is as follows:

[0035]

[0036] Preparation method: first prepare special additives, weigh 20 parts of isooctyl alcohol polyoxyethylene ether, 16 parts of calcium dodecylbenzenesulfonate, 18 parts of diisooctyl sodium sulfosuccinate, 15 parts of sec-octanol and 4 parts of liquid paraffin, placed in a homomixer and stirred until uniform, to obtain.

[0037] Add Emulsogen3510, Dispersogen1494liq, EmulsonAGTRN14105, special additives, ethylene glycol, sodium benzoate, FTRTAF1500 and water weighed in proportion to the stirring tank, stir evenly to obtain a mixed solution A, and then add pendimethalin to the mixed solution A During the addition process, stir constantly, so that the pendimethalin original drug is completely soaked into the mixed solution A, and then stir for another 30 minutes. Put the mixed solution obtained above into a horizontal sand mill for sand grinding in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com