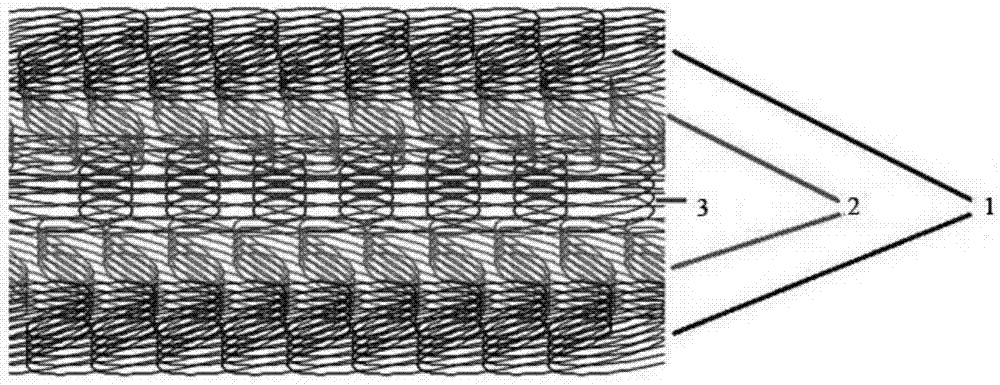

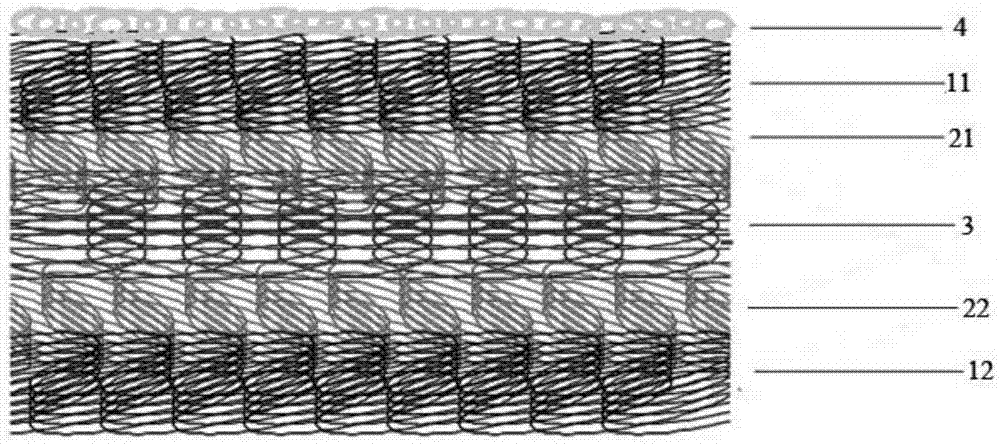

Composite tissue repairing sheet and preparation method thereof

A tissue repair and composite technology, applied in the field of biomedicine, can solve the problems of loss of mechanical strength of woven mesh, decreased repair performance of electrospun membrane, difficult control of processing technology, etc., and achieves good microstructure, microstructure retention, and good repair. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for preparing a composite tissue repair patch, comprising the following steps:

[0037] S1. Preparation of Electrospinning Film Layer A:

[0038] Dissolve PLA in hexafluoroisopropanol solution with a PLA concentration of 8% (g / ml) to obtain a homogeneous polymer solution; put the PLA solution into an electrospinning syringe and adjust the speed of the microsyringe pump to 10mL / h, adjust the voltage of the high-voltage generator to 22KV, adjust the receiving distance of the receiving device to 18cm, perform electrospinning, and close the electrospinning after reaching a thickness of 0.3mm to obtain a PLA electrospinning film layer.

[0039] S2. Preparation of electrospun membrane B:

[0040] Dissolve PCL in hexafluoroisopropanol solution, the concentration of PCL is 20% (g / ml), to obtain a uniform polymer solution, put the PCL solution into the electrospinning syringe, and adjust the speed of the micro syringe pump to 4mL / h, adjust the voltage of the high-...

Embodiment 2

[0044] A method for preparing a composite tissue repair patch, comprising the following steps:

[0045] S1. Preparation of Electrospinning Film Layer A:

[0046] Dissolve PLA in hexafluoroisopropanol solution with a PLA concentration of 6% (g / ml) to obtain a homogeneous polymer solution; put the PLA solution into an electrospinning syringe and adjust the speed of the micro-syringe pump to 8mL / h, adjust the voltage of the high-voltage generator to 20KV, adjust the receiving distance of the receiving device to 20cm, perform electrospinning, and close the electrospinning after reaching a thickness of 0.3mm to obtain PLA electrospinning film layer A.

[0047] Repeat once to prepare two PLA electrospun film layers A in total.

[0048] S2. Preparation of electrospun membrane B:

[0049] Dissolve PCL in hexafluoroisopropanol solution, the concentration of PCL is 18% (g / ml), to obtain a uniform polymer solution, put the PCL solution into the electrospinning syringe, adjust the spee...

Embodiment 3

[0055] A method for preparing a composite tissue repair patch, comprising the following steps:

[0056] S1. Preparation of Electrospinning Film Layer A:

[0057] Dissolve PLA in hexafluoroisopropanol solution with a PLA concentration of 6% (g / ml) to obtain a homogeneous polymer solution; put the PLA solution into an electrospinning syringe and adjust the speed of the micro-syringe pump to 8mL / h, adjust the voltage of the high-voltage generator to 20KV, adjust the receiving distance of the receiving device to 20cm, perform electrospinning, and close the electrospinning after reaching a thickness of 0.3mm to obtain PLA electrospinning film layer A.

[0058] Repeat once to prepare two PLA electrospun film layers A in total.

[0059] One piece of PLA electrospun film layer A is loaded with chitosan anti-adhesion material.

[0060] S2. Preparation of electrospun membrane B:

[0061] Dissolve P4HB in chloroform solution, the concentration of P4HB is 5% (g / ml), to obtain a unif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com