A mesoporous magnetic polymer composite sphere, a preparing method thereof and applications of the composite sphere

A technology of water-soluble polymers and composite spheres, which is applied in the preparation methods of peptides, chemical instruments and methods, and alkali metal compounds, etc., and can solve the problems of reducing magnetic responsiveness, magnetic content of composite microspheres, and lower specific saturation magnetization , to achieve high saturation magnetization, good product stability, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

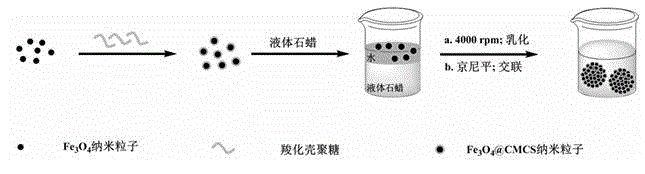

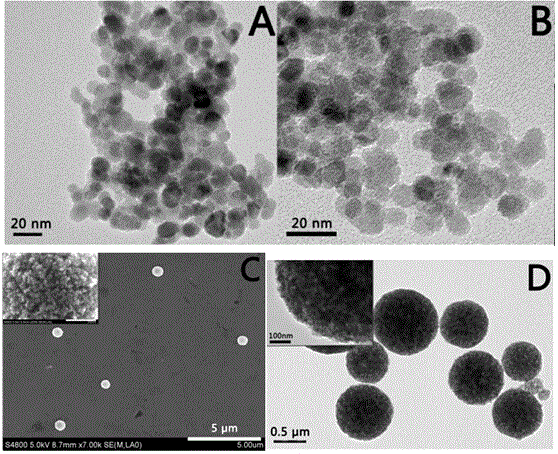

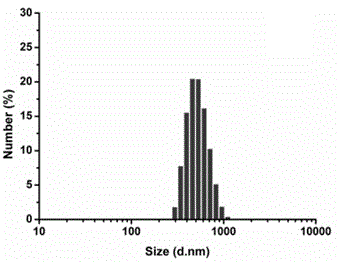

[0044] Example 1 Preparation of Mesoporous Magnetic Polymer Composite Balls

[0045] (1) Fe 3 o 4 Preparation of Superparamagnetic Nanoparticle Suspensions

[0046] Fe 3 o 4 Nanoparticles were synthesized using the traditional co-precipitation method by Fe +2 , Fe +3 Synthesized by co-precipitation with ammonia water. Produced Fe 3 o 4 Dispersed in a certain volume of water to obtain 10mg / ml of Fe 3 o 4 The suspension is ready for use.

[0047] (2) Take 5ml of the above Fe 3 o 4 The suspension was stirred with 5ml of carboxylated chitosan (CMCS) aqueous solution with a concentration of 5mg / ml for 12 hours to obtain Fe with good water solubility 3 o 4 CMCS nanoparticle suspension.

[0048] (3) Add 200ul of the above Fe 3 o 4 The CMCS nanoparticle suspension was added to 10ml liquid paraffin containing 3mlspan80, homogenized and dispersed (4000rpm, 10min) to obtain water-in-oil hybrid droplets.

[0049] (4) Add 25mg of genipin, 1000rpm, 60°C, stir for 4 hours...

Embodiment 2

[0058] (1) Fe 3 o 4 Preparation of Superparamagnetic Nanoparticle Suspensions

[0059] Fe 3 o 4 Nanoparticles were synthesized using the traditional co-precipitation method by Fe +2 , Fe +3 Synthesized by co-precipitation with ammonia water. Produced Fe 3 o 4 Dispersed in a certain volume of water to obtain 10mg / ml of Fe 3 o 4 The suspension is ready for use.

[0060] (2) Take 5ml of the above Fe 3 o 4 The suspension was stirred with 5ml of acrylic acid aqueous solution with a concentration of 5mg / ml for 12 hours to obtain Fe with better water solubility 3 o 4 Acrylic Nanoparticle Suspension.

[0061] (3) Add 200ul of the above Fe 3 o 4 The suspension of acrylic acid nanoparticles was added to 10ml of liquid paraffin containing 3mlspan80, homogenized and dispersed (4000rpm, 10min) to obtain water-in-oil hybrid droplets.

[0062] (4) Add 25mg of ammonium persulfate (APS), 1000rpm, 60°C, stir for 4 hours to initiate acrylic acid polymerization, stabilize the emu...

Embodiment 3

[0067] (1) Preparation of superparamagnetic nanoparticle suspension

[0068] superparamagnetic Fe 2 o 3 Disperse in a certain volume of water to obtain 10mg / ml Fe 2 o 3 The suspension is ready for use.

[0069] (2) Take 25ml of the above Fe 2 o 3 The suspension was stirred with 50 ml of chitosan (CS) aqueous solution with a concentration of 5 mg / ml for 6 hours. Produces Fe with better water solubility 2 o 3 CS nanoparticle suspension.

[0070] (3) Add 1ml of the above Fe 2 o 3 The CS nanoparticle suspension was added to 10ml liquid paraffin containing 6mlspan80, homogenized and dispersed (2000rpm, 5min) to obtain water-in-oil hybrid droplets.

[0071] (4) Add 50mg of glutaraldehyde, 1000rpm, 60°C, stir for 4h, cross-link chitosan, stabilize the emulsification system, and gradually form mesoporous CS / Fe 2 o 3 compound ball.

[0072] The product is characterized by the same method as in Example 1, and the results show that the obtained product is the same as the CM...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com