Composite photocatalyst SiO2/CNI, preparation method therefor and application in field of hydrogen production by water photolysis

A catalyst and compound light technology, applied in chemical instruments and methods, physical/chemical process catalysts, hydrogen production, etc., can solve the problems of low hydrogen content, high raw material cost, limited increase in photocatalytic efficiency of modified catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 5

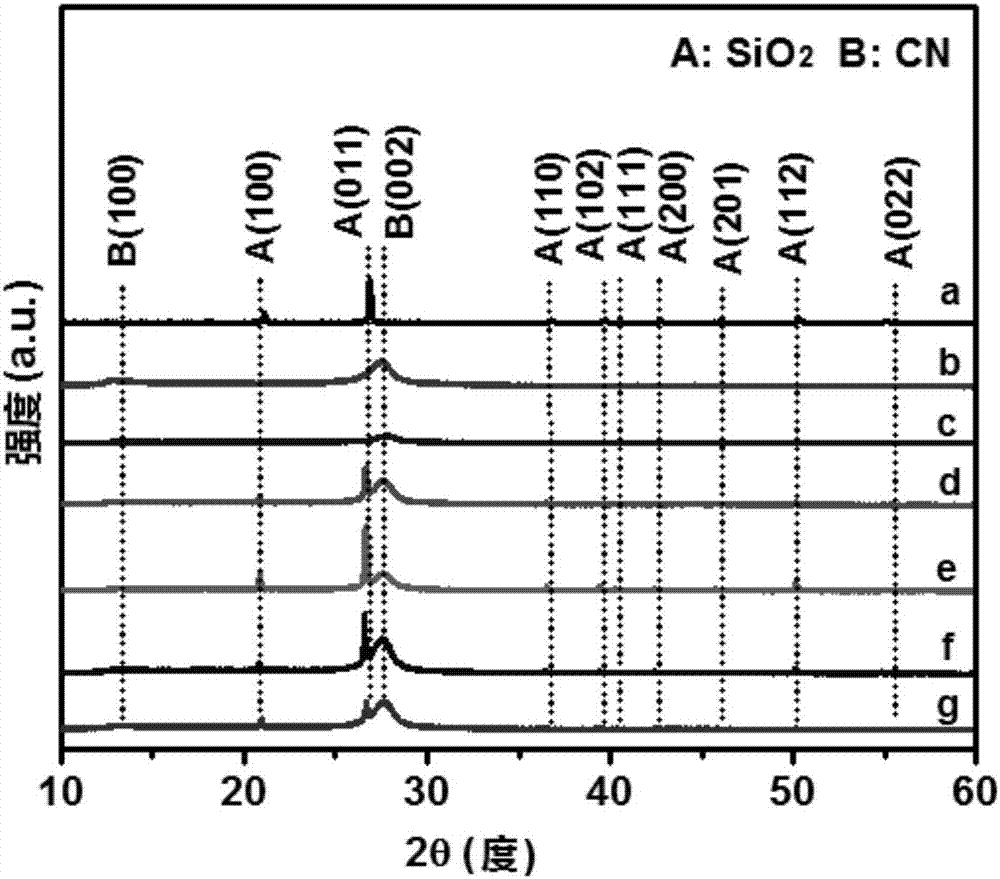

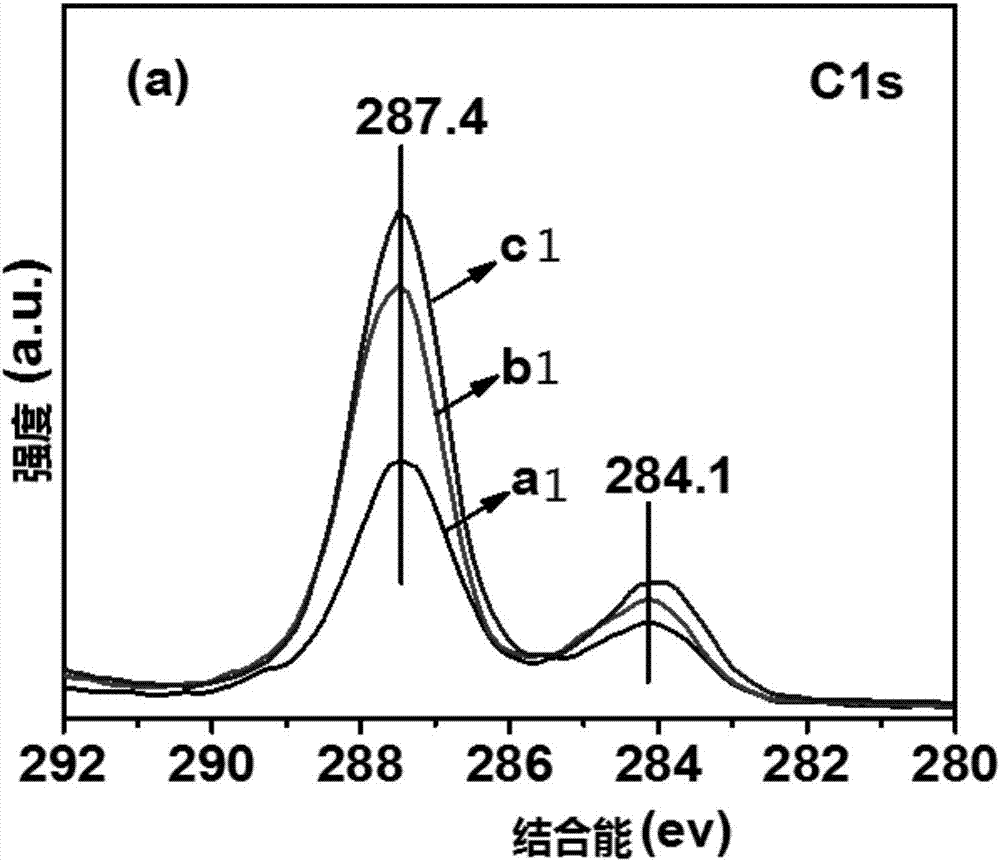

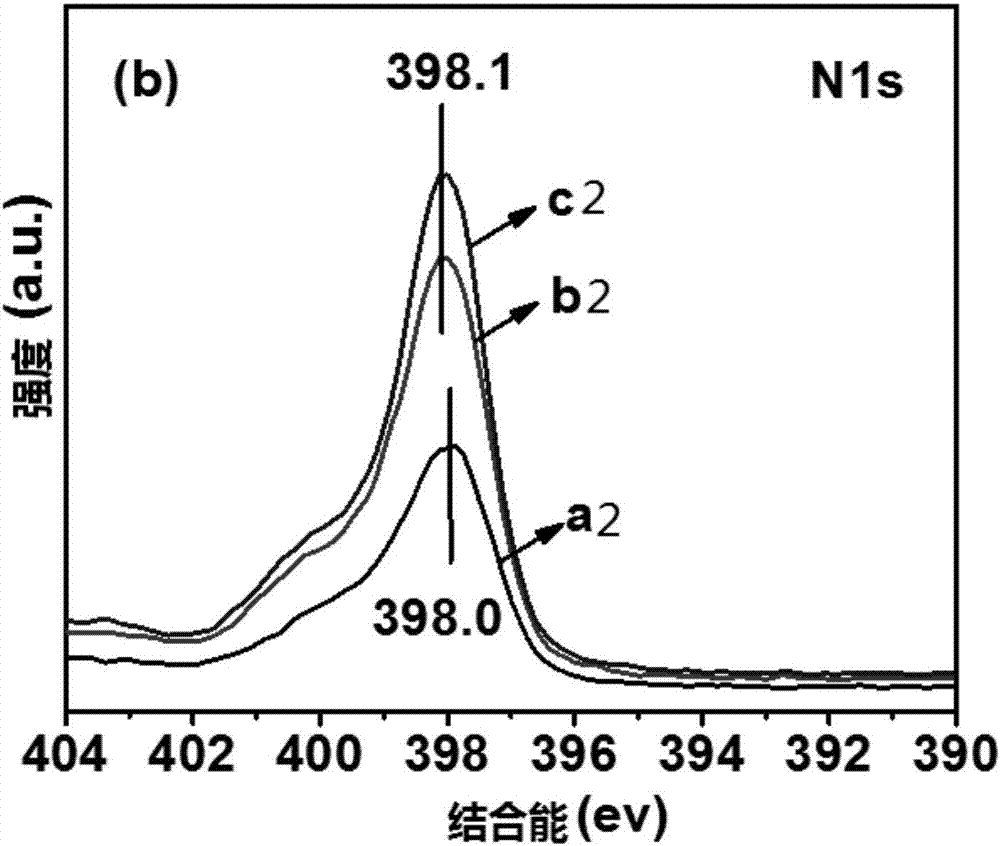

[0046] The inventors have found through research that SiO 2 The carrier has the characteristics of surface dispersion effect, large specific surface area and porous structure. When SiO 2 Carbon nitride with graphite phase (g-C 3 N 4 ) after recombination to form a binary semiconductor composite photocatalyst, its photocatalytic activity is significantly improved, and is not bound by any theory. The stages can be transferred and separated, thereby prolonging the life of the carriers, thereby improving the photocatalytic reactivity.

[0047] According to a third aspect of the present invention, there is provided a method for preparing the above-mentioned composite photocatalyst SiO 2 The method of / CNI is characterized in that, the method comprises the following steps:

[0048] Step 1, mixing the nitrogen-containing organic matter with the iodine-containing compound, calcining, optionally cooling, and then purifying to obtain a CNI sample.

[0049] In the present invention, ...

Embodiment 1

[0094] (1) Accurately weigh 2.0g of dicyandiamide and 1.0g of ammonium iodide in a small beaker (ammonium iodide should be weighed in the dark), add 10ml of deionized water, and place the small beaker in a water bath at 80°C Evaporate to dryness in a water bath at 80°C for 6 hours; put the obtained sample into an agate mortar and grind it finely, then put it in a crucible and place it in a box-type resistance furnace for calcination at 550°C for 4 hours, then take it out, cool the obtained sample to room temperature, and grind Finely pack into the sample bag to prepare the CNI catalyst as it is;

[0095] The obtained CNI was transferred as it was to a small beaker filled with 80 mL of distilled water, then washed with water, acid washed (HCl, 1mol / L), alkali washed (NaOH, 1mol / L), washed with water again, and suction filtered to remove all unreacted harmful Surface substance: Put the treated sample in an oven at 80°C and dry for 5 hours. After the drying is completed, grind th...

Embodiment 2~4

[0098] The method used in embodiment 2~4 is similar to embodiment 1, difference is only in step (2) SiO 2 The weights are 0.2000g, 0.1200g and 0.1000g respectively, and the composite catalysts prepared are SiO 2 / CNI(1:15), SiO2 2 / CNI(1:25), SiO2 2 / CNI (1:30).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com